A kind of method for preparing betamethasone intermediate

A betamethasone and strain technology, applied in the field of steroid biopharmaceuticals, can solve the problems of low input amount of recombinant strains, chemical synthesis pollution, low conversion rate, etc., to increase the risk of impurities, rich sources, and reduce production costs. and the effect of environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Arthrobacter simplex CPCC 140451 was used as the transformed strain.

[0065] (1) Strain slant culture process: use a 500mL eggplant-shaped bottle, according to the following ratio: glucose 13g / L, yeast extract 16g / L, agar 18g / L, pH7.0-8.0 to prepare slant medium, each eggplant-shaped After sterilizing 100mL of bottled liquid at 121°C for 30 minutes, set up the slope, and place it in a 32°C incubator for 2 days after the slope solidified and formed. After culturing at 32°C for 2 days, the eggplant-shaped bottles were collected and placed in a refrigerator at 4°C until use.

[0066] (2) Strain shake flask culture process: use 500mL shake flask, according to the following ratio: glucose 11.8g / L, corn steep liquor 6g / L, peptone 8g / L, KH 2 PO 4 4g / L, pH7.0-8.0 to prepare shake flask seed medium and fermentation transformation medium, each shake flask liquid 100mL, in which 1.0g / L compound I was added as induction before the fermentation transformation medium was sterilize...

Embodiment 2

[0068] Embodiment 2: Take Arthrobacter simplex CPCC 140451 as the transformation strain

[0069] (1) Strain slant culture and shake flask culture process: same as Example 1, the difference is that 1.5 g / L compound I was added as induction before the fermentation transformation medium was sterilized.

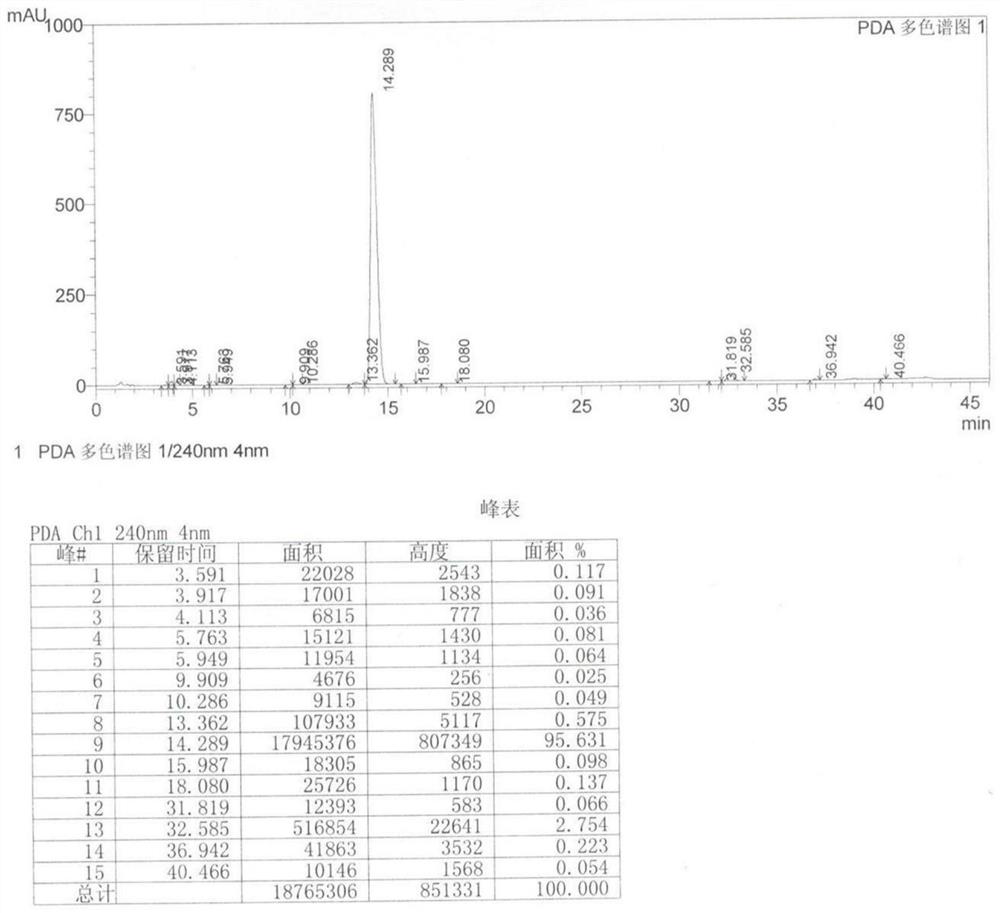

[0070] (2) Feed conversion process: add 10% ammonia water to the cultured 100mL fermentation broth, adjust the pH value to 9.5, weigh 6g of compound I, put it into a shaker flask, add 0.1% DMF (V / V), shake well Afterwards, the transformation was carried out at 34°C and 220rpm for 70 hours. After the transformation was completed, the temperature was raised to 70°C to terminate the reaction. Take 1mL of the transformation solution, add 20mL of acetone and sonicate it for 30min, and perform HPLC analysis after centrifugation. The conversion rate was 93.136%.

Embodiment 3

[0071] Embodiment 3: Take Arthrobacter simplex CPCC 140451 as the transformation strain

[0072] (1) Strain slant culture and shake flask culture process: same as Example 1, the difference is that 2.0 g / L compound I was added as induction before the fermentation transformation medium was sterilized.

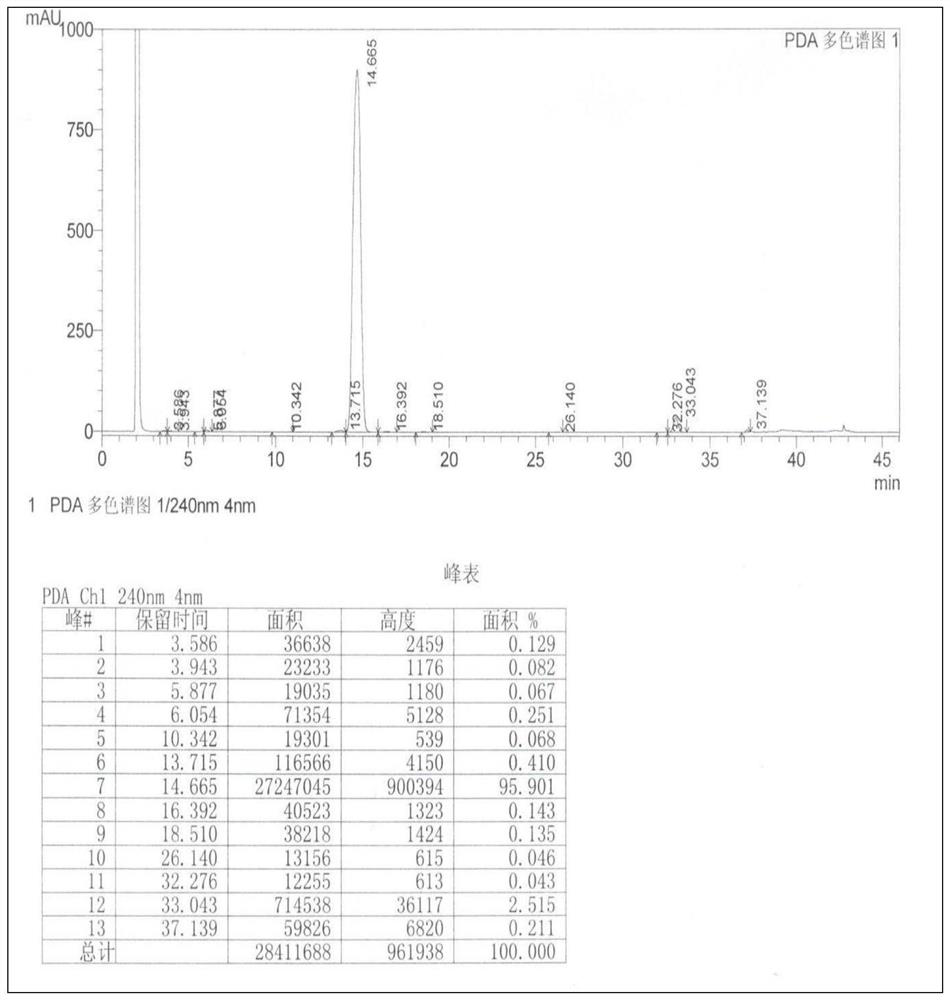

[0073] (2) Feed conversion process: add 15% aqueous sodium hydroxide solution to the cultured 100mL fermentation broth, adjust the pH value to 10.0, weigh 5g of compound I, put it into a shaker flask, add 0.1% DMSO (V / V) After shaking well, transform at 32°C transformation temperature and 220rpm rotation speed for 65 hours. After the transformation is completed, raise the temperature to 80°C to terminate the reaction. Take 1mL transformation solution, add 20mL acetone and sonicate for 30min, and perform HPLC analysis after centrifugation. The transformation rate is 94.632%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com