Installing system and method of matrix type system artistic chandelier

An installation system and installation method technology, applied in lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of non-cross construction, high installation height of chandeliers, long construction period, etc., saving time and cost, and efficient construction. Convenience and the effect of reducing welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

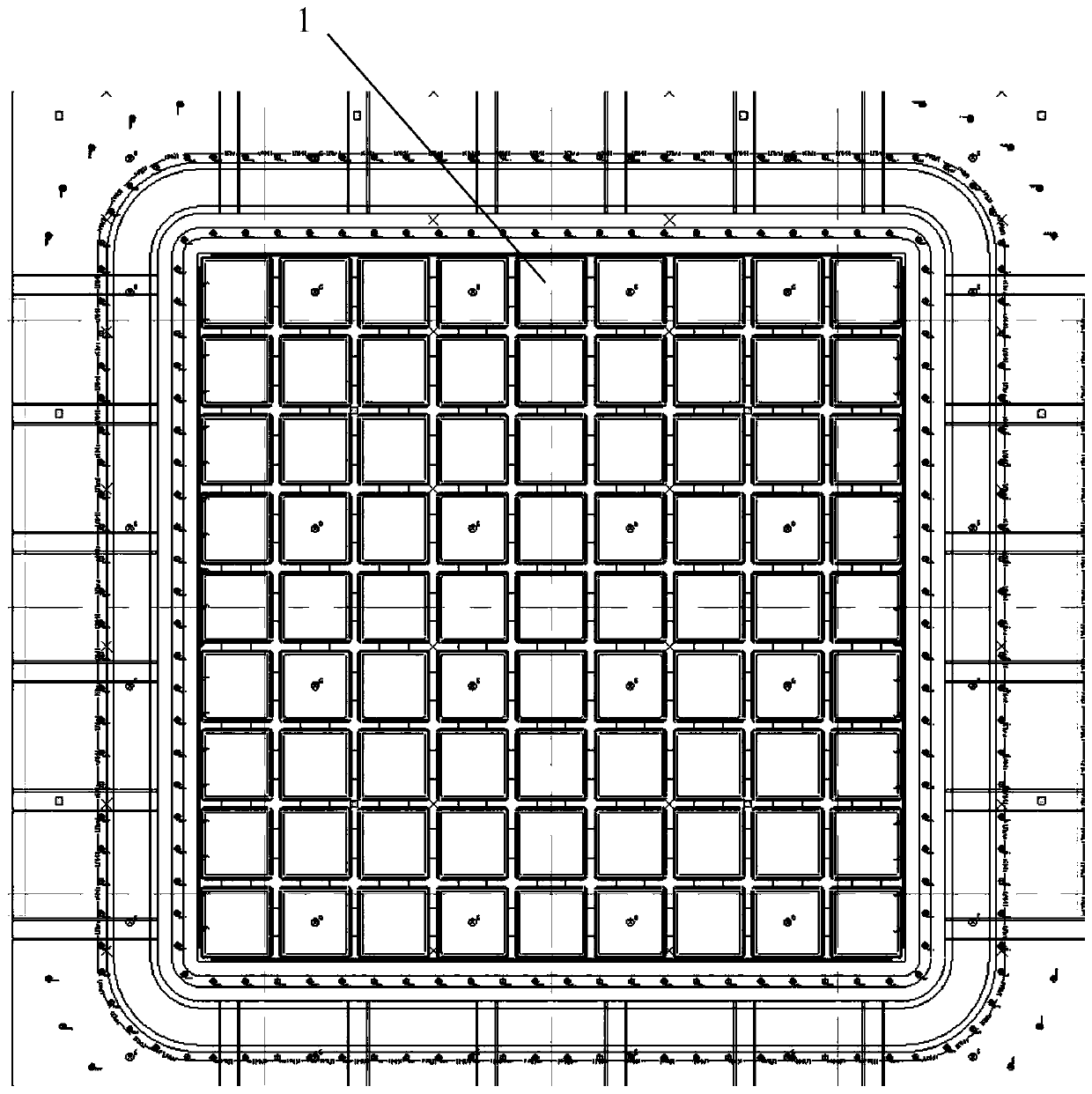

[0054] figure 1 It is the overall schematic diagram of the matrix pendant lamp installation system in this embodiment.

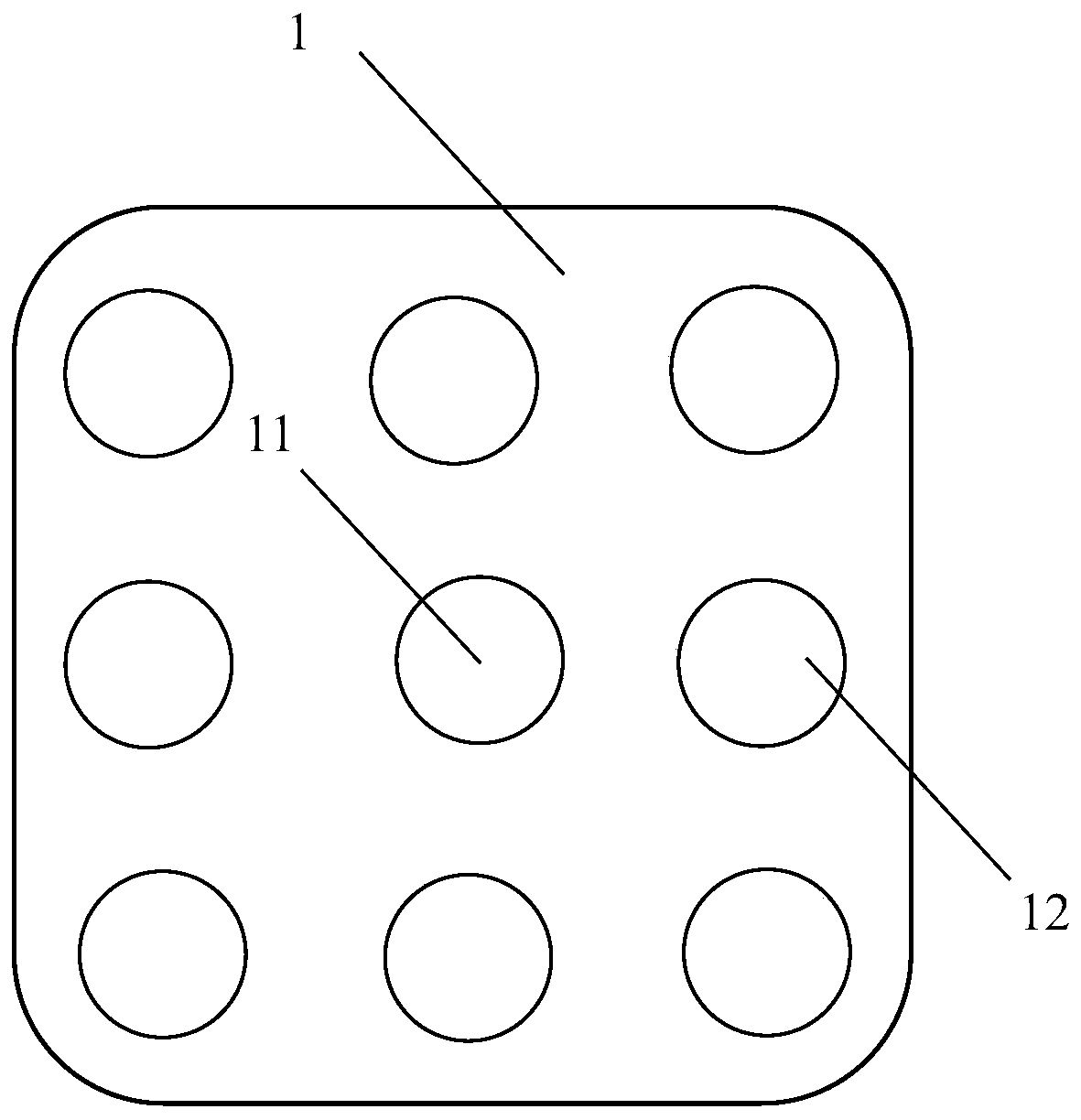

[0055] figure 2 It is a schematic diagram of a single chandelier installation point in this embodiment.

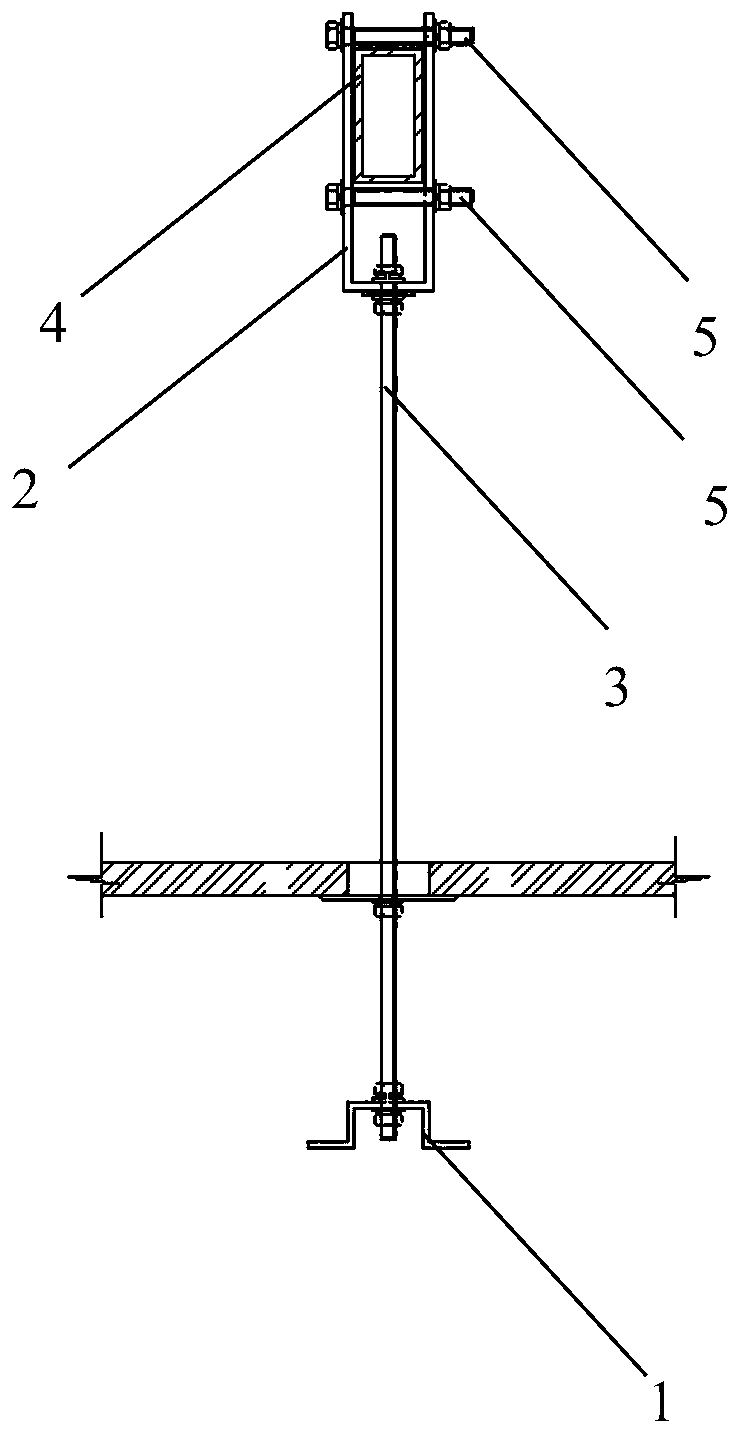

[0056] image 3 It is a schematic diagram of the installation structure of a single chandelier in this embodiment.

[0057] Such as figure 1 , figure 2 , image 3 As shown, this embodiment proposes an integral pendant light installation system, which is installed on the main steel frame of the suspended ceiling, including: a first number of pendant lights 1, a second number of fixing members 3, a second number of connecting members 2, and a conversion Layer steel frame 4.

[0058] Wherein, the first number of pendant lamps 1 have a second number of installation points, and the steel frame 4 of the conversion layer has a second number of hanging points, and the above-mentioned installation points and the hanging points are installed in one-to-one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com