Corrosion protection for air-cooled condensers

An air-cooled, corrosion-protected technology used in steam/vapor condensers, instrumentation, damage protection, etc. to solve problems such as reduced heat transfer efficiency, equipment downtime, and reduced product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

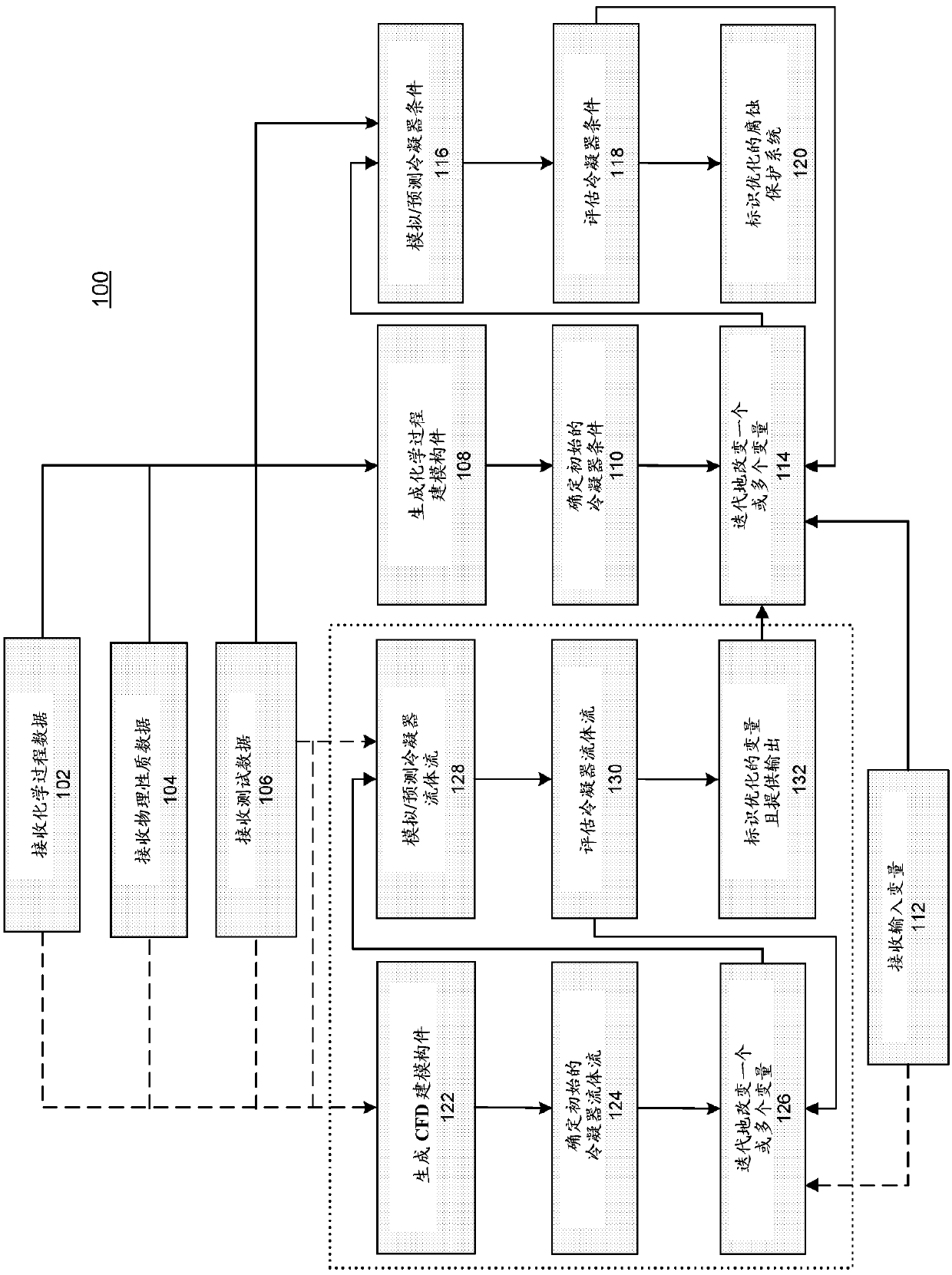

[0016] A method for developing an optimized corrosion protection system for air-cooled condensers is disclosed. The generated model was used to optimize the treatment and supply of corrosion inhibitors to the vapor system of an air-cooled condenser in order to inhibit and minimize corrosion. In general, a corrosion inhibitor is any substance that effectively reduces the rate of corrosion when added to the environment. Inhibitors can be identified with respect to their function (eg, removal of corrosive species, passivation, precipitation, or adsorption). The solution optimizes, for example, the chemistry of corrosion protection feed, timing, feed rate and feed point.

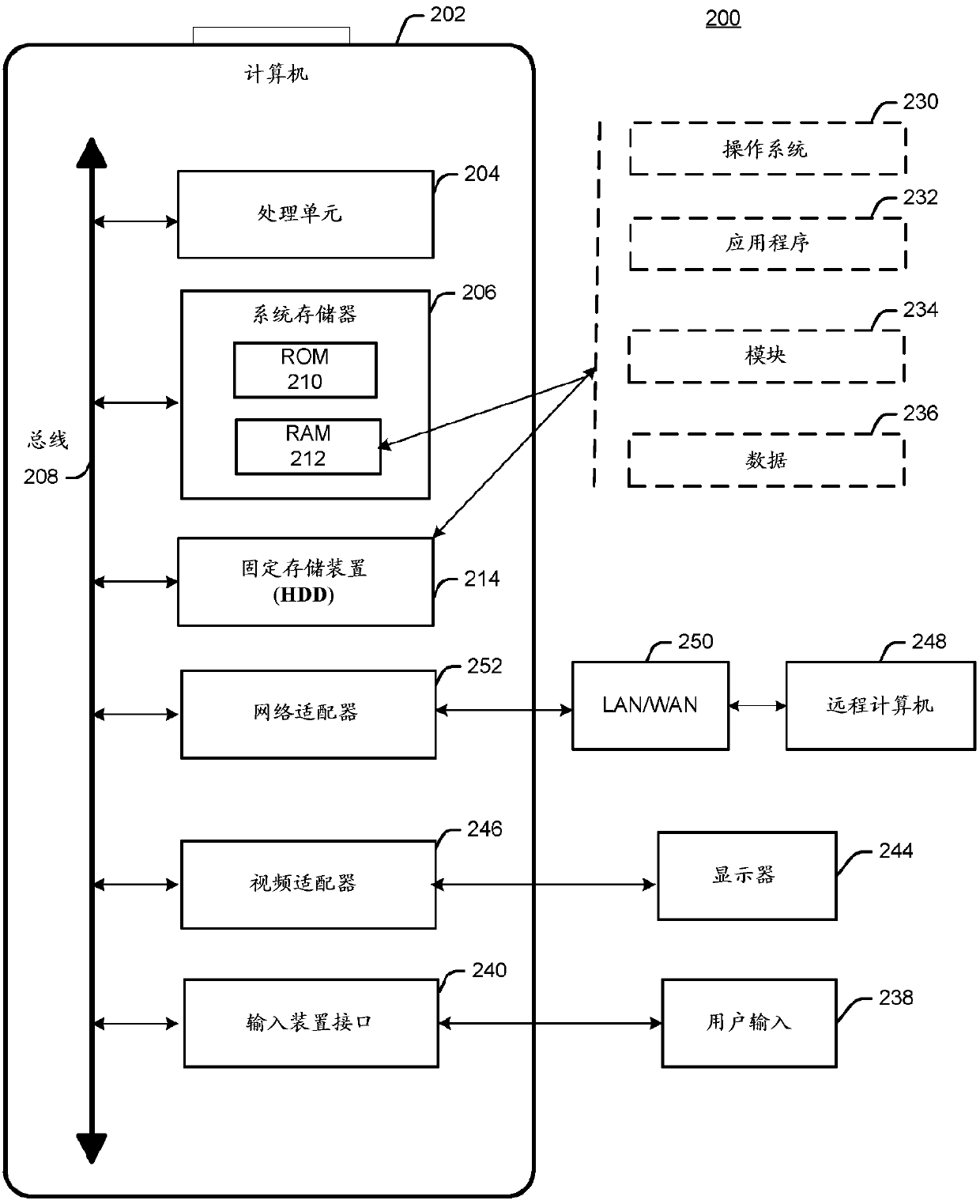

[0017] In an embodiment, a computer-implemented method for establishing a corrosion protection system for an air-cooled condenser utilizes one or more processors and associated memory storing one or more programs executed, the one or more programs including instructions for: receiving data associated with at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com