Glass debris collection system for solar cell module lamination production line

A technology for solar cell components and glass fragments, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve problems such as discomfort and inconvenience, achieve simple cleaning work and improve cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals.

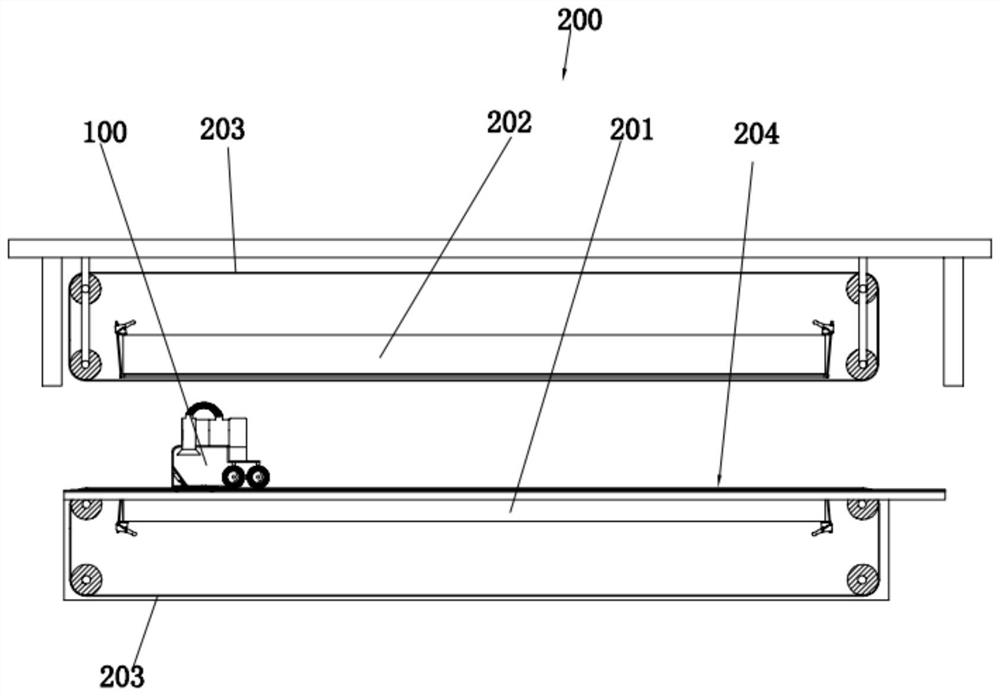

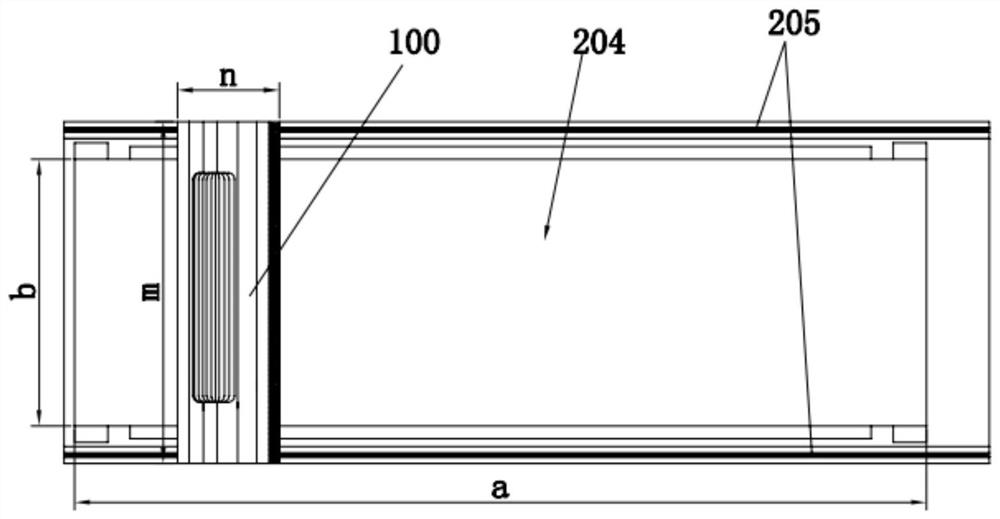

[0035] combine figure 1 and figure 2 As shown, the part of the upper surface of the high-temperature cloth 203 above the lower lamination platform 202 of the laminator 200 is defined as the first cleaning surface 204, wherein the length direction of the first cleaning surface 204 is the same as that of the high-temperature cloth 203 on this surface. The conveying direction is parallel, and the general laminator 200 explosion plate is directly broken on the first cleaning surface 204, such as figure 2 As shown, the length a of the first cleaning surface 204 and the width b of the first cleaning surface 204 .

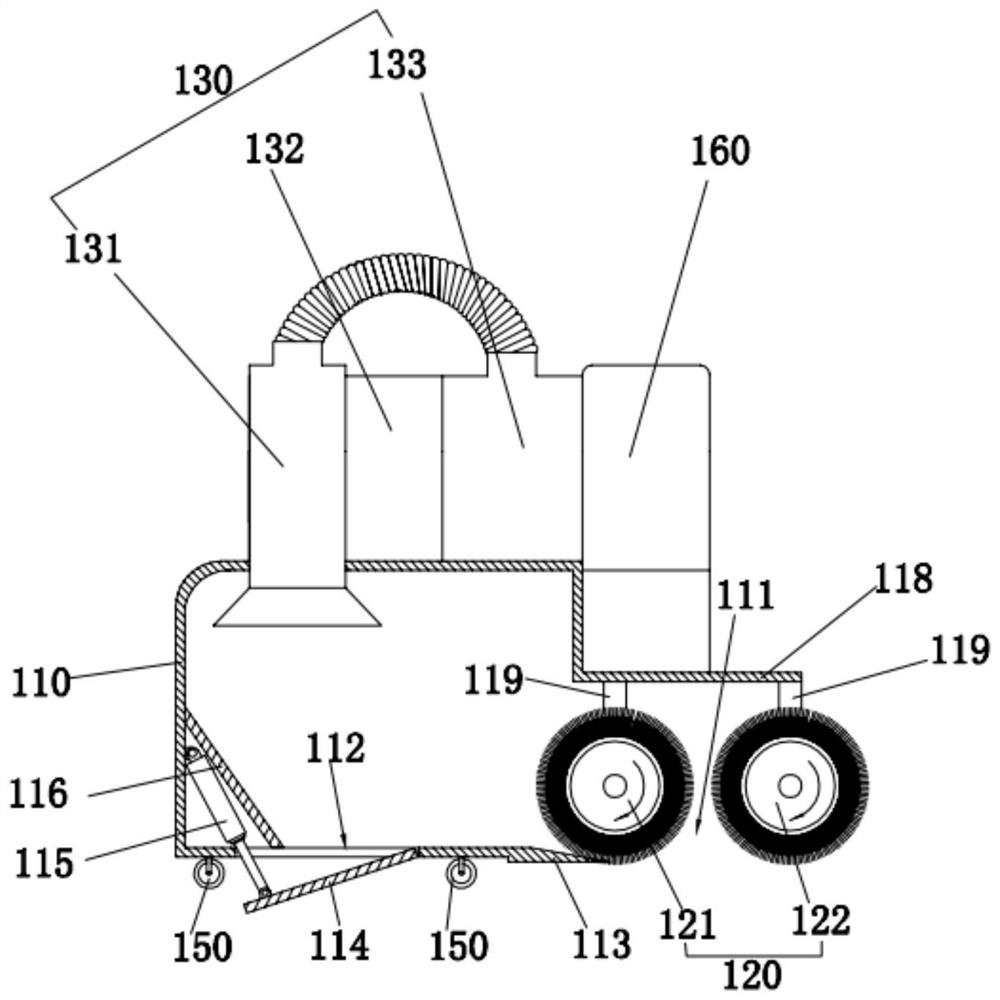

[0036] A glass shard collection system 100 of a solar cell module lamination production line is used to collect glass shards that explode on a laminator 200, such as image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com