Platform type machine tool bed

A platform type, machine tool technology, applied in the field of data machine tools, can solve the problems of poor lubrication effect on the top surface of tailstock guide rails and high tail guide rails, and achieve the effects of reducing friction, enhancing lubrication effect and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

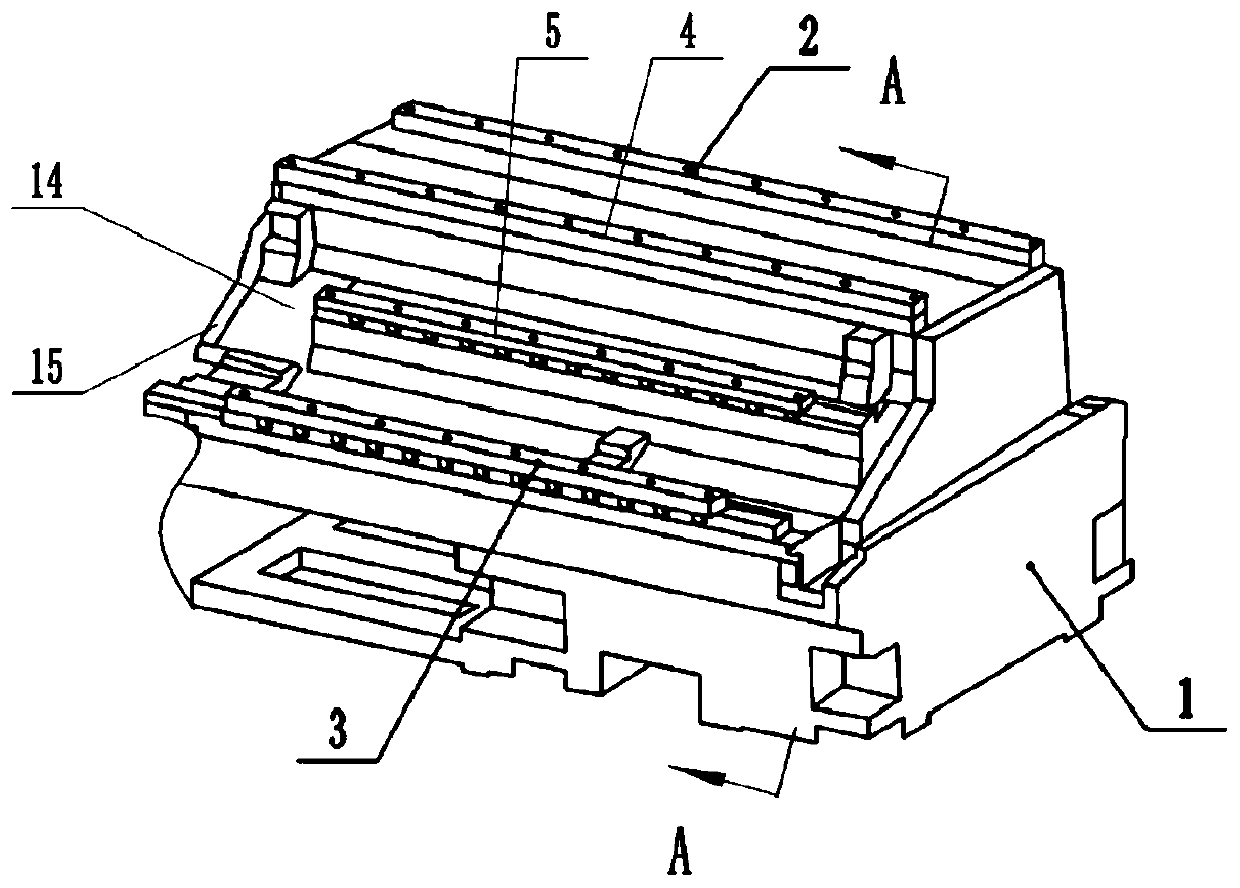

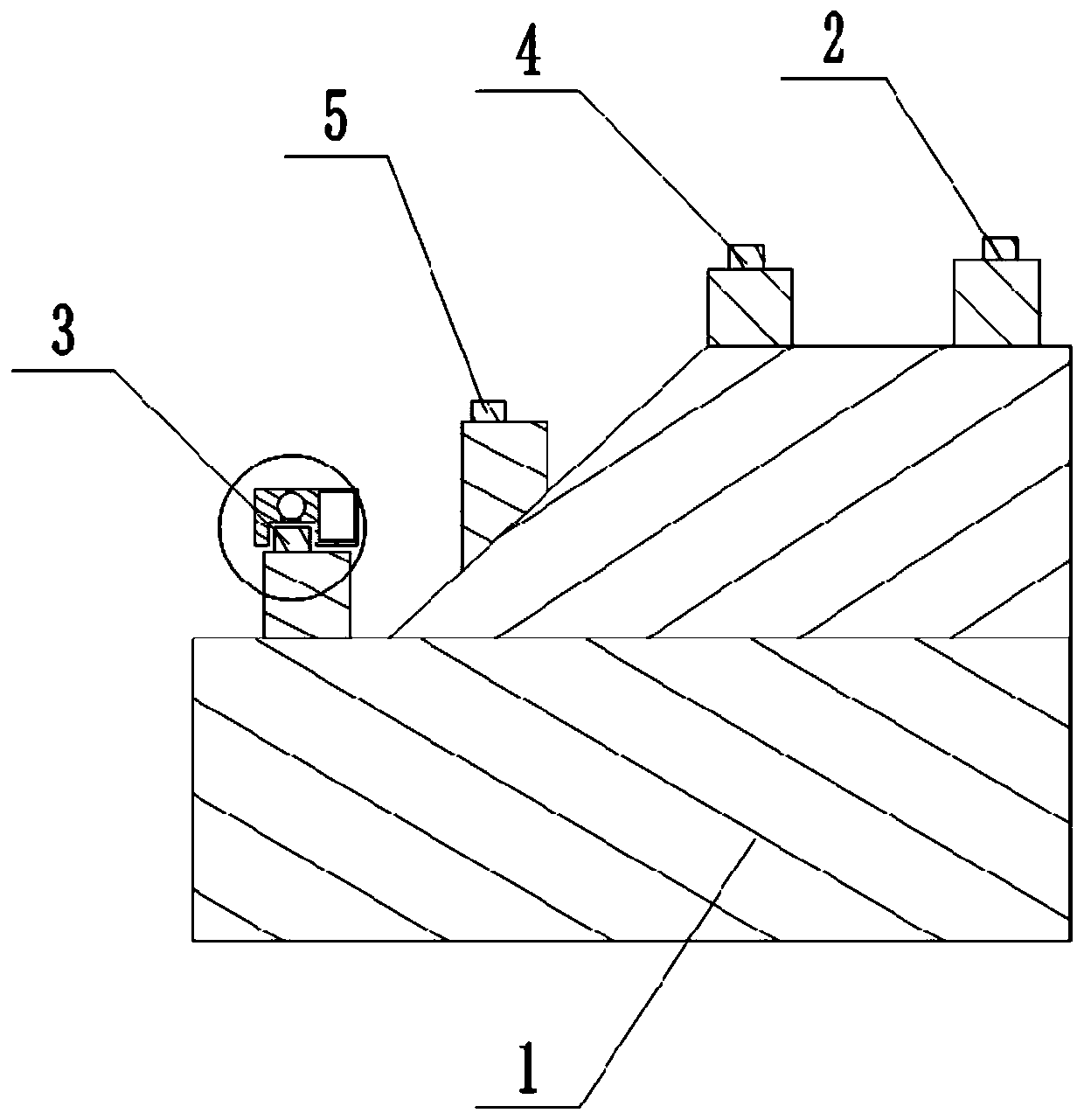

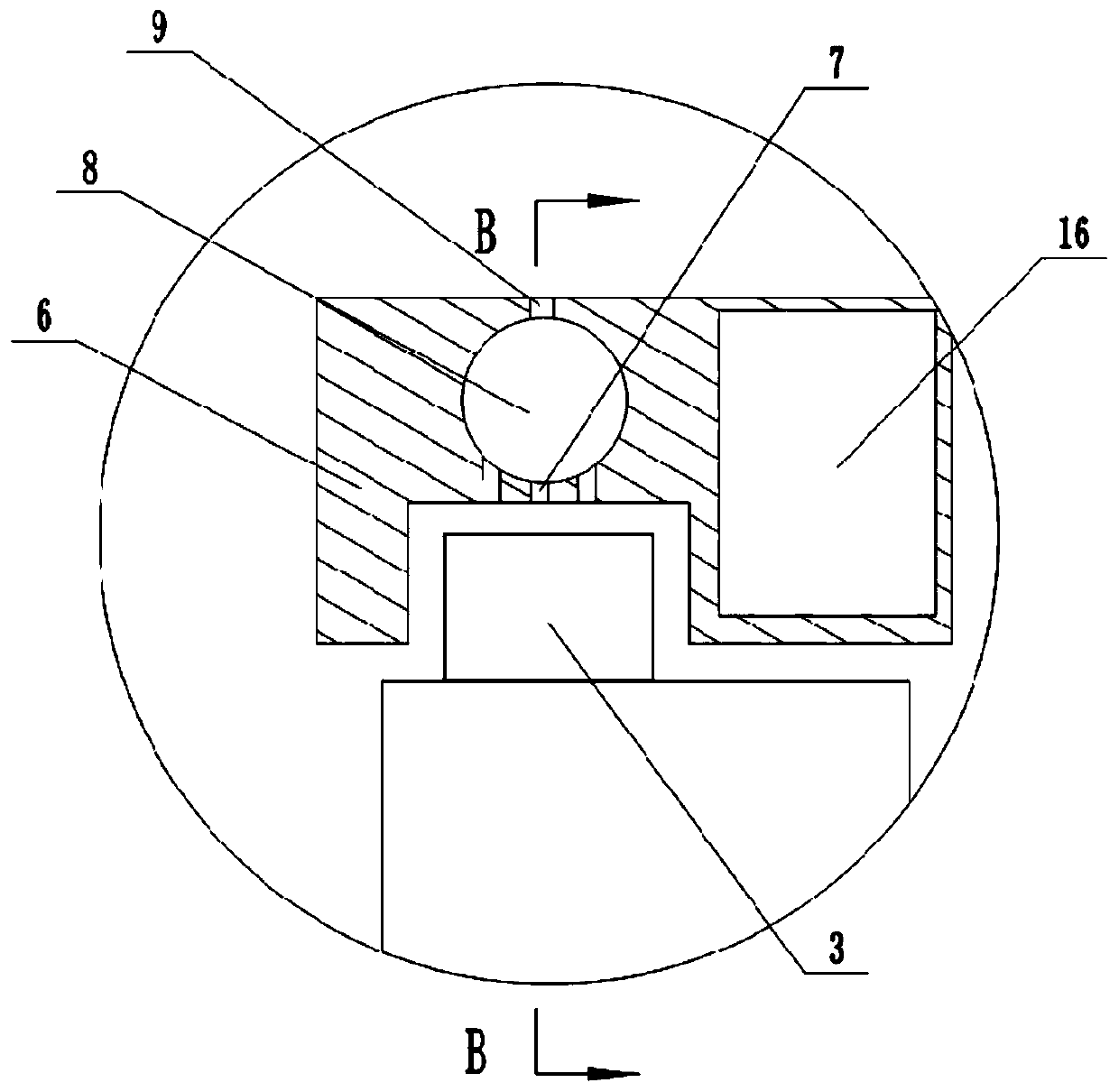

[0037] Basic as attached figure 1 , figure 2 Shown: a platform type machine bed, including a bed base 1 and a tailstock guide rail, the tailstock guide rail is fixedly installed on the top surface of the bed base 1 longitudinally (the length direction of the bed base 1), and the number of tailstock guide rails is two, For the convenience of description, the two tailstock rails are named the first tailstock rail 3 and the second tailstock rail 5 respectively. The first tailstock rail 3 and the second tailstock rail 5 are arranged horizontally in steps. The top surfaces of a tailstock guide rail 3 and a second tailstock guide rail 5 are both parallel to the positioning base surface at the bottom of the bed base 1, and a slider 6 is slidably connected to the first tailstock guide rail 3 and the second tailstock guide rail 5 to The slider 6 on the first tailstock guide rail 3 is taken as an example to illustrate the structure of the slider 6, such as image 3 , Figure 4 As shown, ...

Embodiment 2

[0044] Such as Image 6 , Figure 7 As shown, the difference between this embodiment and the first embodiment is that the driving mechanism includes a mounting portion 12 and a wiper 13 that are fixedly connected to each other by bolts. The wiper 13 is erected on the tailstock rail and attached to the tailstock rail. In the cleaning layer, the friction damping between the wiper 13 and the tailstock rail is greater than the friction damping between the slider 6 and the tailstock rail. Here, the slider 6 is made of stainless steel and the wiper 13 is made of rubber as an example; the free end of the piston rod 11 and the installation The part 12 is fixedly connected by bolts.

[0045] Such as Image 6 As shown, when in use, the tailstock assembly slides back and forth on the guide rail to drive the slider 6 to slide back and forth synchronously. When the sliding block 6 moves to the left, the wiper 13 moves to the right relative to the sliding block 6, thereby driving the piston 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap