Magnetofluid hydraulic grinding wheel and controllable finishing processing method

A finishing process and magnetic fluid technology, applied in the direction of bonded grinding wheel, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult adjustment of the size of the processing area, poor processing quality, low processing efficiency, etc., and achieve obvious magneto-rheological effect , improve the processing quality, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

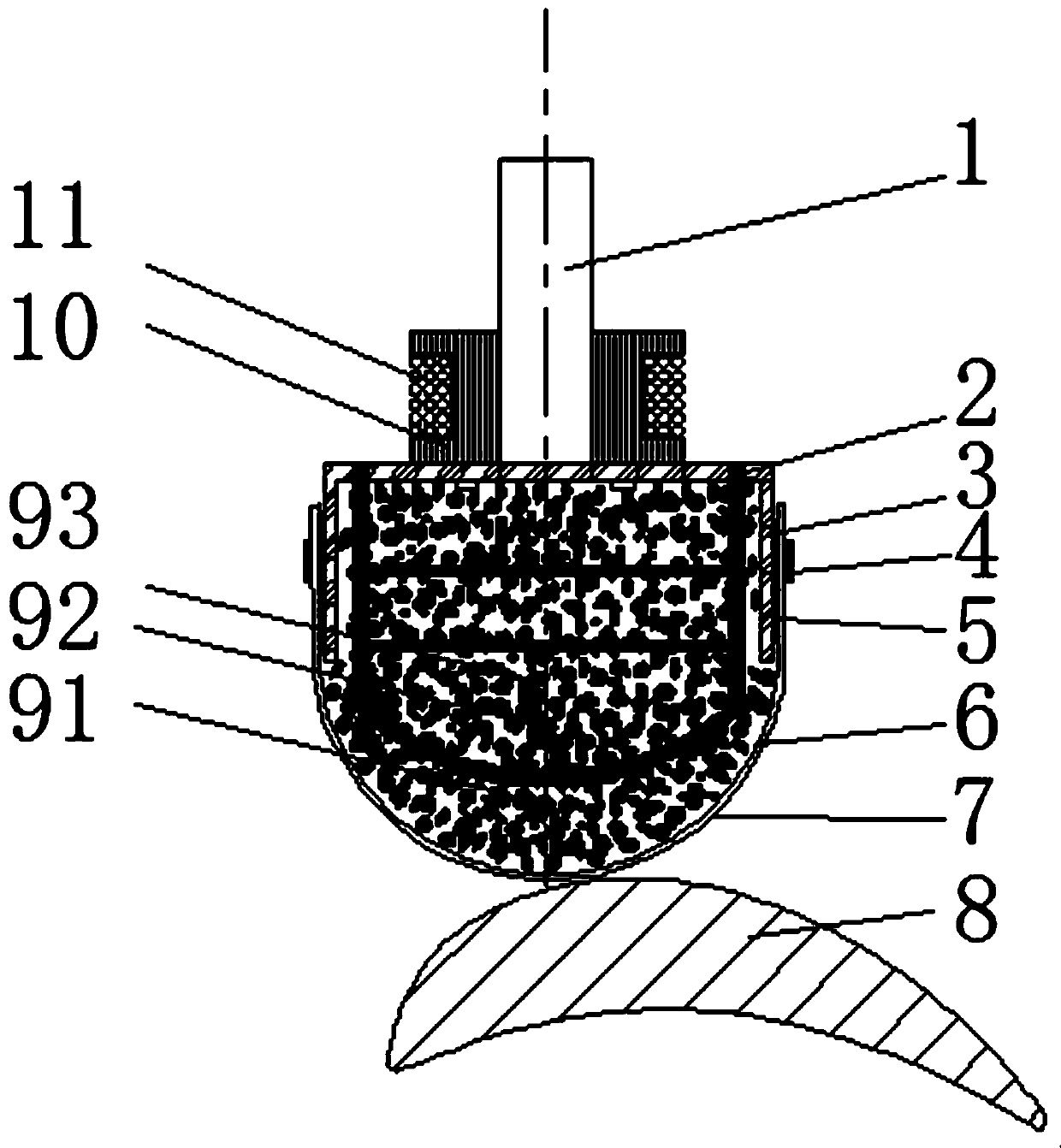

[0042] combine figure 1 , figure 2 , Image 6 , a magnetic fluid hydraulic grinding wheel, which is connected to the main shaft 1 of the machine tool, including a spherical crown grinding wheel 7, a grinding wheel base 3, and a magnetic field generating device;

[0043]The grinding wheel base 3 is connected to the main shaft 1, and the grinding wheel base 3 is provided with a magnetic field generating device and a spherical crown grinding wheel 7, and a magnetic fluid is sealed between the spherical crown grinding wheel 7 and the grinding wheel base 3, and the spherical crown grinding wheel 7 is a flexible rubber-based diamond Grinding wheel; a fastening ring 4 is also provided between the spherical crown grinding wheel 7 and the grinding wheel base 3 . Based on Pascal's law, after the magnetic fluid is squeezed by the workpiece 8, the internal static pressure will be transferred to the entire surface of the workpiece 8 in contact with the spherical crown grinding wheel 7, ...

Embodiment 2

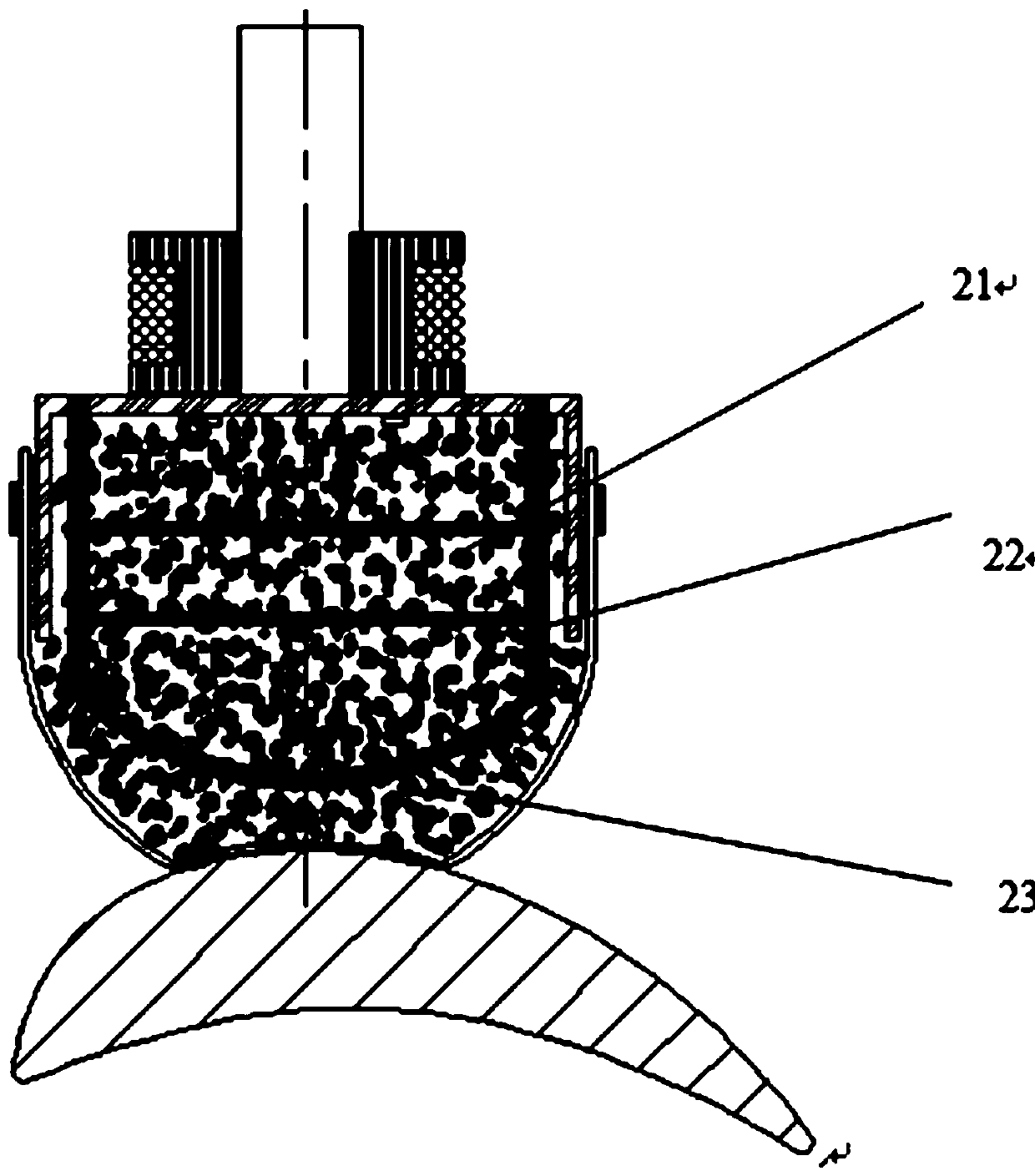

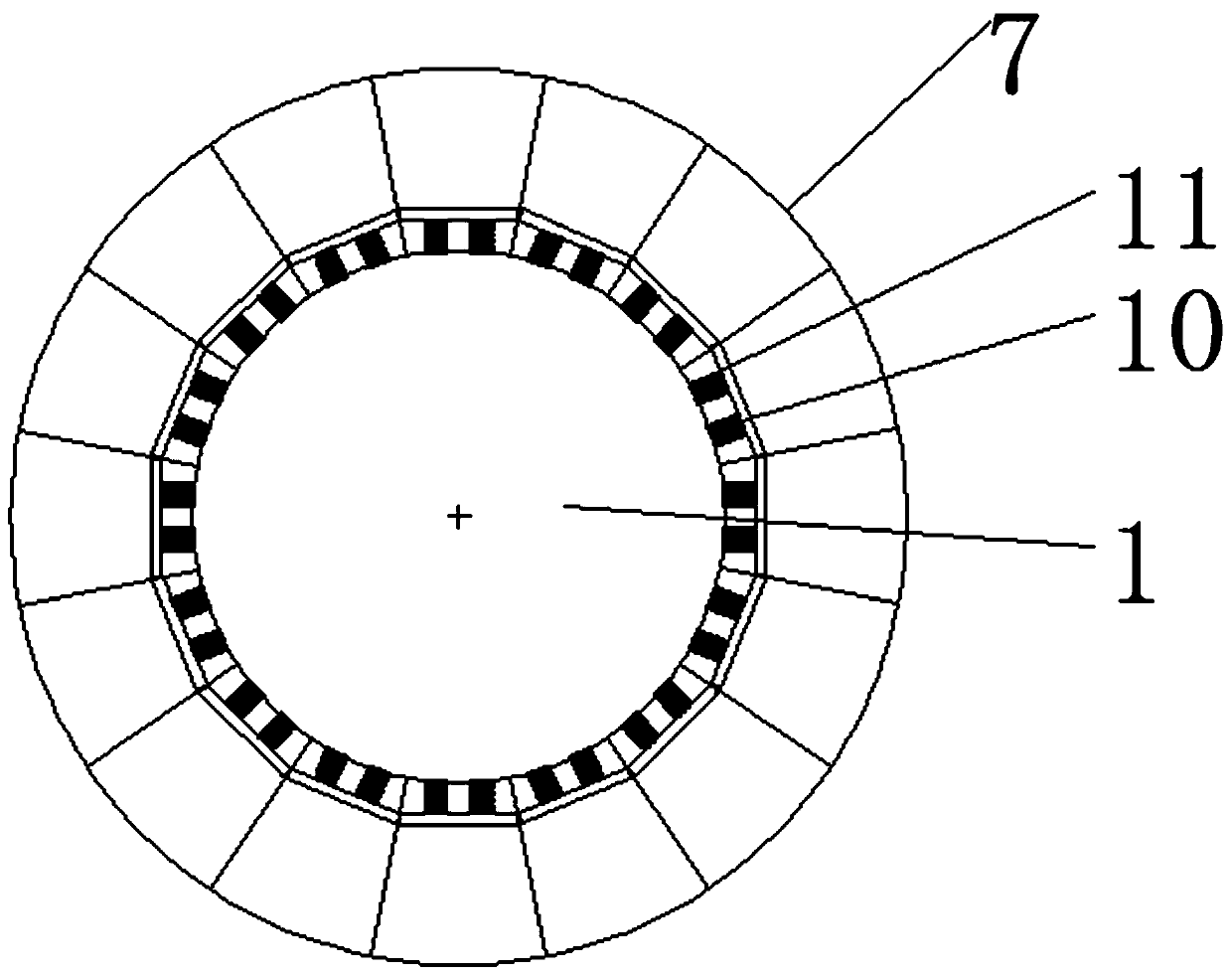

[0056] In combination with Example 1 and figure 2 , image 3 , Figure 4 , The difference from Embodiment 1 is that in this embodiment, the installation and layout of the hydraulic grinding wheel and the main shaft 1 are different. In this embodiment, the hydraulic grinding wheels are evenly distributed around the main shaft 1, and the spherical crown grinding wheels 7 of multiple hydraulic grinding wheels form an annular abrasive belt. At the same time, the spherical crown grinding wheel 7 of the hydraulic grinding wheel is in the shape of a fan-shaped plate, and a plurality of spherical crown grinding wheels 7 in the shape of a fan-shaped plate form an annular grinding wheel.

Embodiment 3

[0058] In combination with Example 1 and figure 2 , image 3 , Figure 4 , Figure 5 , the difference with embodiment 2 is that, in addition to forming the annular grinding wheel, the hydraulic grinding wheel in the annular grinding wheel can rotate, and the present embodiment also includes the following parts;

[0059] The rotating motor 12 is fixedly arranged on the main shaft 1 and is used to drive the hydraulic grinding wheel. At this time, the end face of the spherical crown grinding wheel 71 of the hydraulic grinding wheel is an arc surface;

[0060] A planetary gear 13, one end is connected with the drive shaft of the rotating electrical machine 12, and the other end is meshed with the axial internal teeth of the ring gear 14;

[0061] The ring gear 14, its inner ring side wall is provided with the axial inner teeth meshed with the planetary gear 13, its lower end surface (from Figure 5 Seen from the middle direction) is provided with a face gear matching with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com