Free-form surface uniform copying grinding device and grinding method

A profiling grinding and uniform technology, which is applied in the parts of grinding machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of uneven grinding force and difficult to control, so as to improve the processing quality and reduce the processing efficiency. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

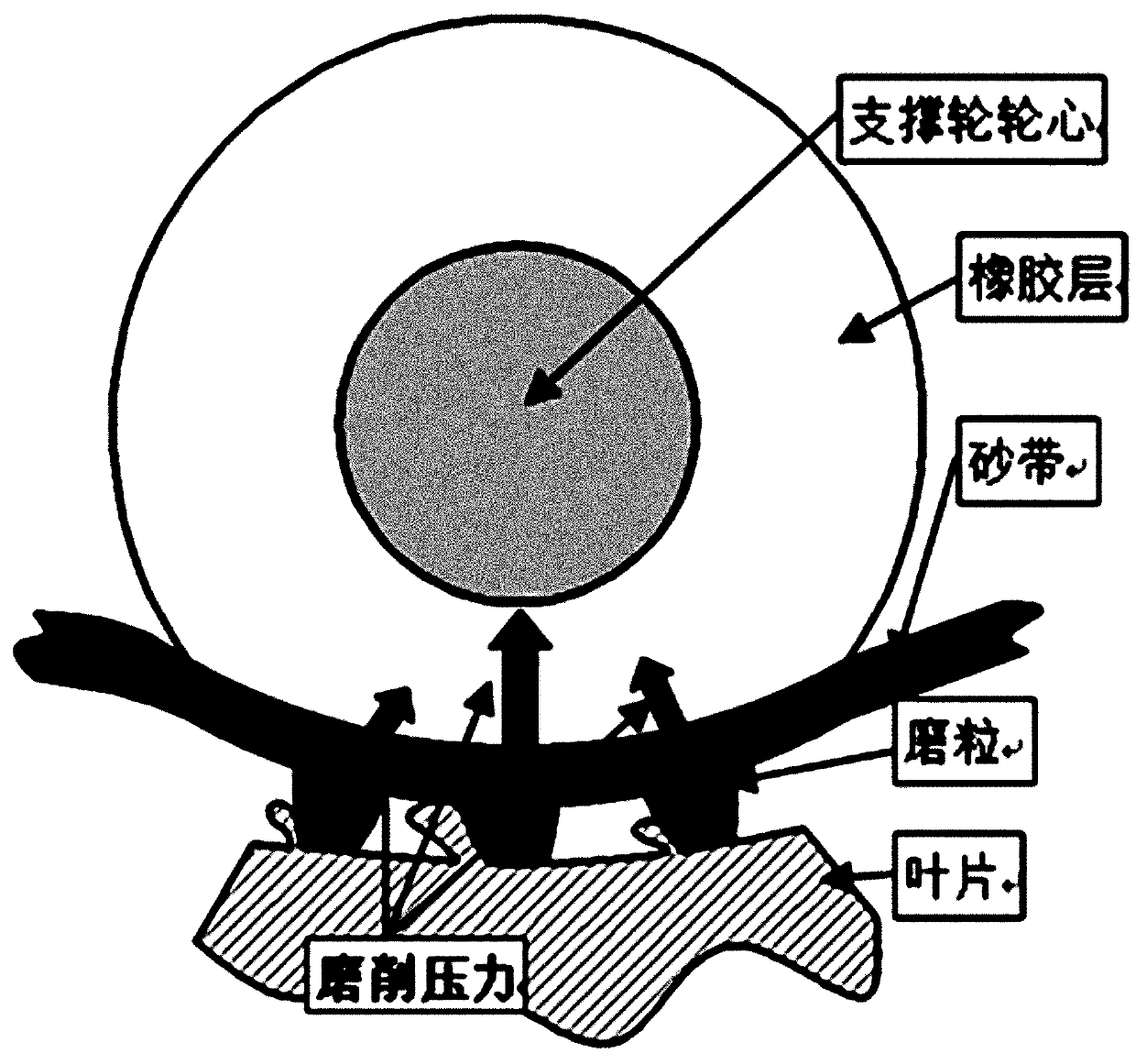

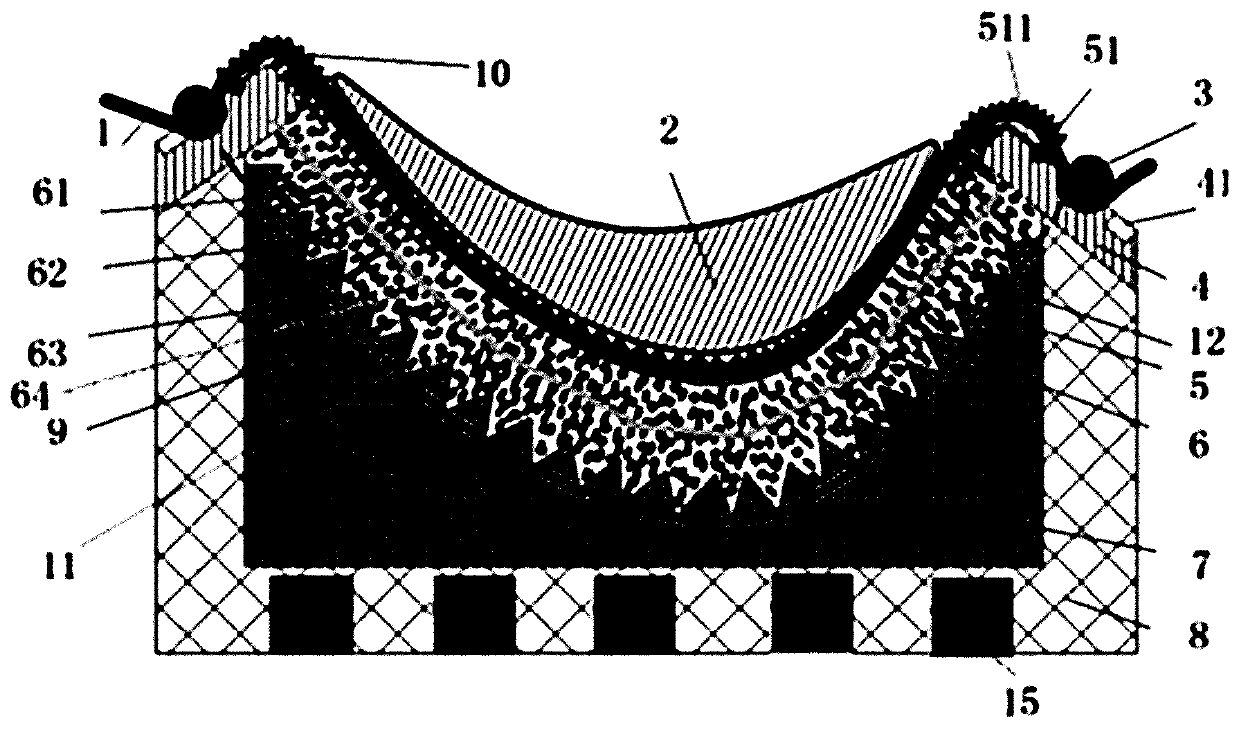

[0048] combine figure 1 , figure 2 , Figure 5 , a free-form surface uniform profiling grinding device and method, comprising a profiling grinding abrasive belt 1, a profiling grinding head 7, which drives the abrasive belt by a drive mechanism (the drive mechanism uses an abrasive belt drive part of the prior art or Commercially available products generally at least include a driving wheel, a tensioning wheel, a speed change mechanism, and a power assembly, which will not be described one by one in this patent) and are attached to the surface of the workpiece 2 for grinding; the profiling grinding head 7 is provided with There is a profiling surface 11 matching the surface shape of the workpiece 2; a profiling force application mechanism, which includes a magnetorheological glue 6; Between the glue container 8 and the profiling grinding head 7; the magnetorheological glue 6 is also provided with a profiling inner cooling channel 9. A profiling inner cooling channel 9 is s...

Embodiment 2

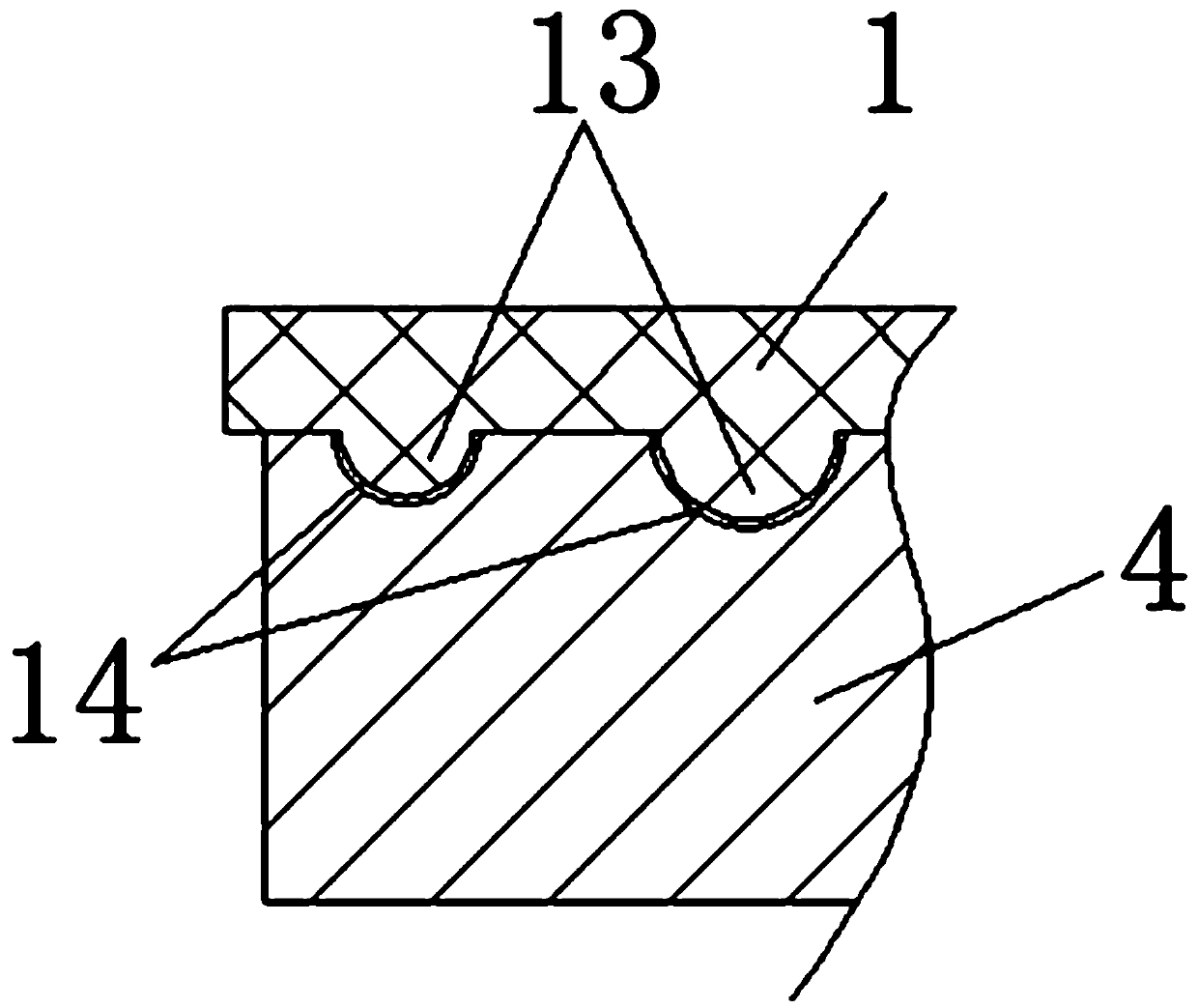

[0068] In combination with Example 1 and image 3 , Figure 4 , the difference with Embodiment 1 is that in this embodiment, no elastic-enhanced rubber pad 5 and rubber pad fastening ring 51 are provided, and both sides of the profiling grinding abrasive belt 1 are provided with a sliding seal assembly, which includes concave-convex Cooperating chute 14 and slide rail 13, slide rail 13 is arranged on the profiling grinding abrasive belt 1, specific position is the both sides of abrasive belt movement direction, and chute 14 is arranged on the top outside of grinding head. It is also possible to use a mode in which the chute 14 is arranged on the profiling grinding belt 1 and the slide rail 13 is arranged on the grinding head. The profiling grinding abrasive belt 1 uses a grinding abrasive belt with a flexible substrate, and is also provided with a sealable sealing layer or sealing glue on the abrasive belt. In this example figure 2 Among them, the chute 14 is set on the li...

Embodiment 3

[0071] In conjunction with Example 1, and Image 6, the difference from Example 1 is that the magnetorheological glue is also provided with a magnetorheological glue rod 16, which includes a rubber sleeve, and its inner seal is filled with magnetorheological glue 6, and the rubber sleeve is arranged in a rod shape. Its top is in contact with the inner side of the abrasive belt or the inner side of the rubber gasket, and the bottom is connected or in contact with the profiling surface of the profiling grinding head through a spring (not shown in the figure). The limit groove of the above-mentioned spring; the outside of the rubber sleeve is also provided with ordinary fluid (such as silicone oil), which can enhance its overall fluidity and improve the rapid response and uniformity of hydrostatic pressure.

[0072] During specific implementation, in this case, the workpiece presses the abrasive belt and compresses the magneto-rheological glue stick 16. At this time, the spring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com