Circular goods shelf temporary storage system

A caching system and racking technology, applied in the field of circular rack caching system, can solve the problems of reducing the efficiency of the outbound and warehousing of turnover boxes, increasing the movement path of robots, and storing a small number of turnover boxes, etc., so as to shorten the movement path and occupy more space. The effect of small area and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

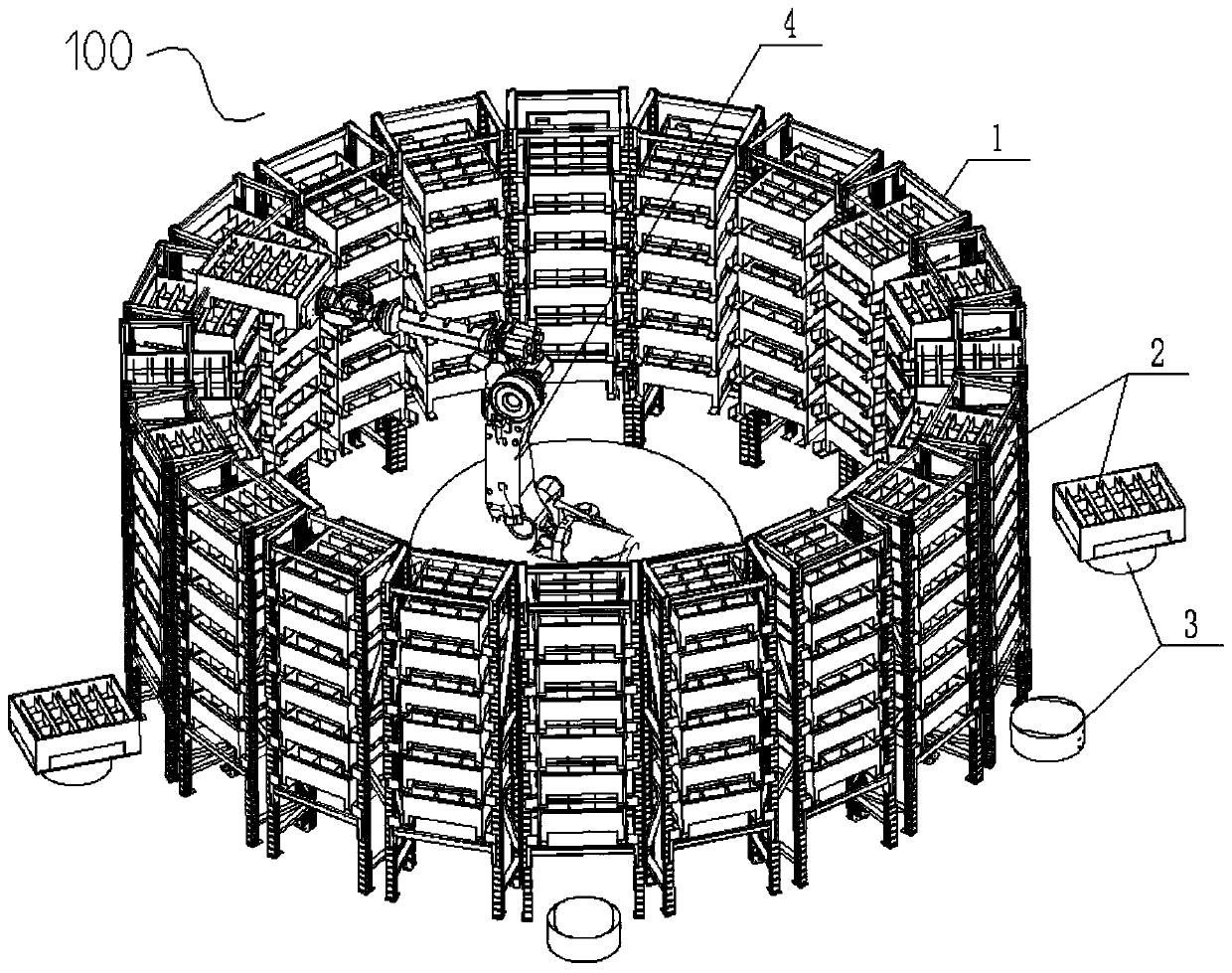

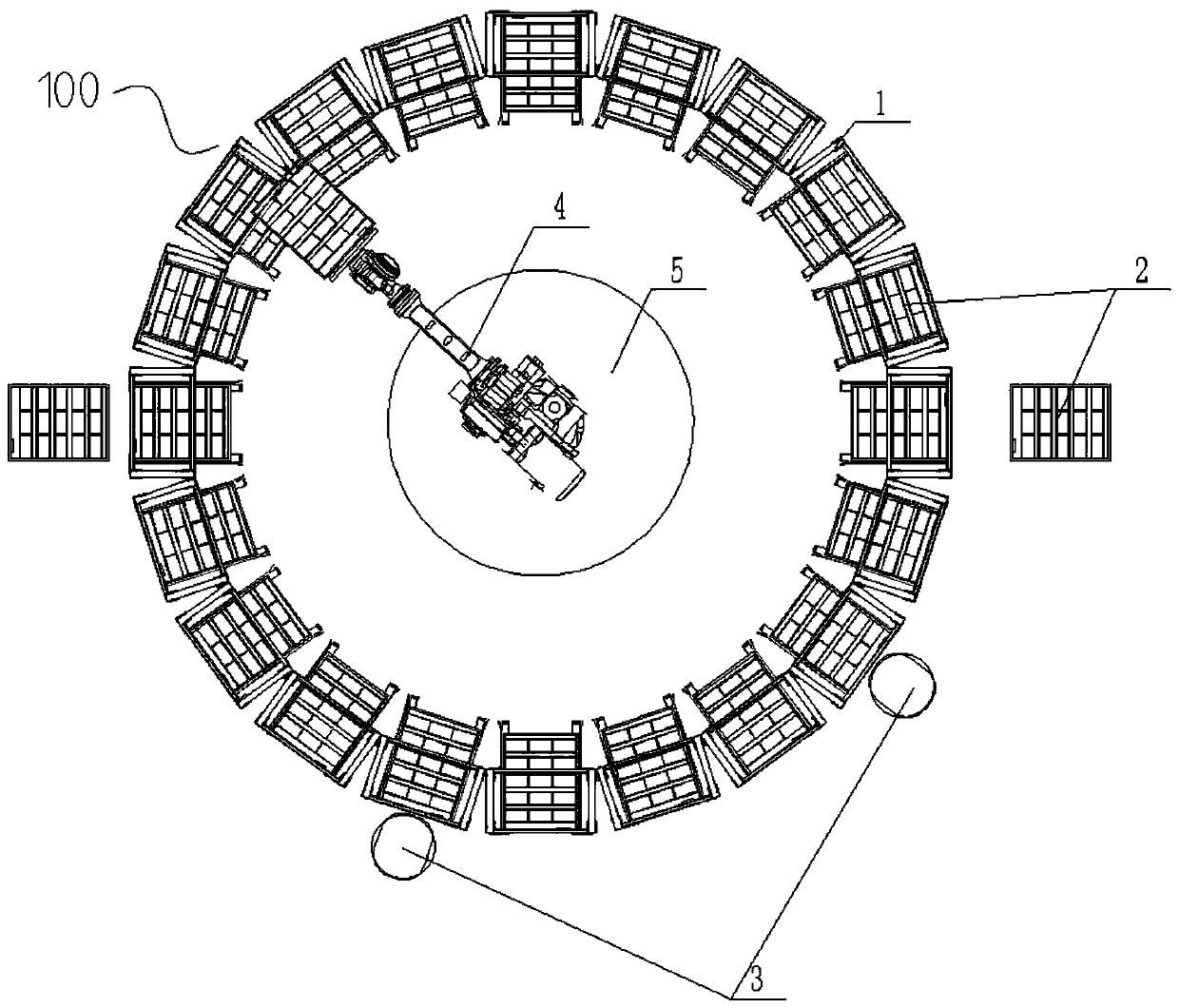

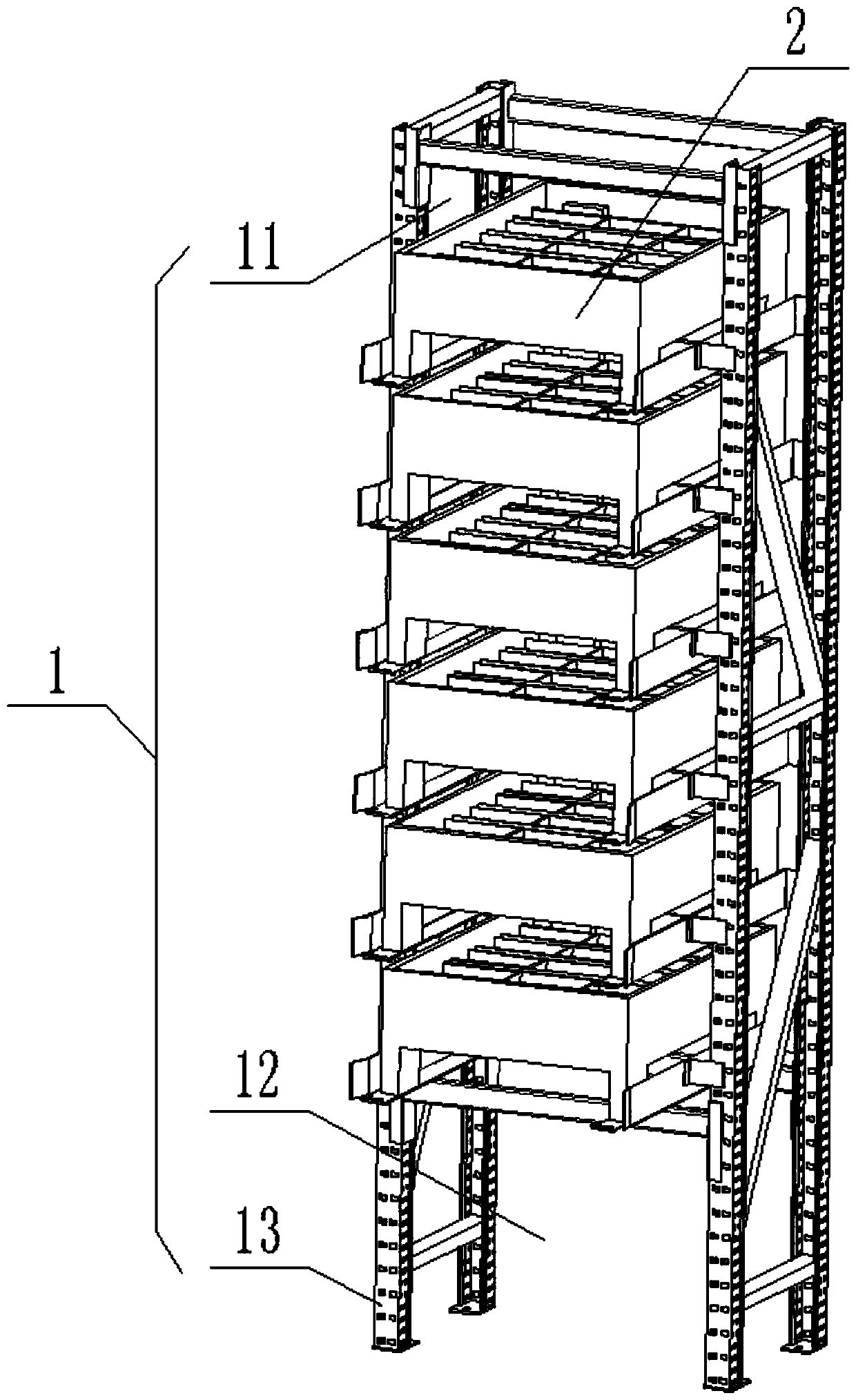

[0038] see Figure 1-8 , the present embodiment provides a circular shelf buffering system, the circular shelf buffering system includes a buffer storehouse 100, a transport vehicle 3 and a robot 4, the buffer storehouse 100 includes a plurality of shelves 1 distributed along the circumference, each shelf 1 has It includes a storage compartment 11 and a transportation compartment 12, and the storage compartment 11 is used for placing the turnover box 2. The transport vehicle 3 can load the turnover box 2 , and enters and exits the buffer warehouse 100 through the transport slot 12 . The robot 4 is located in the center of the buffer warehouse 100 , and the robot 4 can drive the turnover box 2 to switch between the shelving grid 11 and the transport vehicle 3 . Such a setting makes it unnecessary to set additional openings for the output and storage of the turnover boxes 2 in the buffer warehouse 100, increases the number of storage turnover boxes 2, and improves the utilizati...

Embodiment 2

[0050] see Figure 6 and Figure 7 , different from the above-mentioned embodiment one, in order to improve the stability of the bracket, a reinforcing rib 135 is provided on the bracket 13, and the two ends of the reinforcing rib 135 are installed on the two adjacent pillars 131 respectively, so that it is connected with the two A triangular stable area is formed between the pillars 131. According to the characteristics of the stability of the triangle, the strength of the bracket 13 is improved, thereby improving the stability of the shelf 1, so that the turnover box 2 is placed on the shelf 1 more stably.

[0051] In this embodiment, the specific number of reinforcing ribs 135 is not limited, and can be adjusted according to the specific weight of the turnover box 2, as long as the strength requirement can be met.

[0052] In addition, preferably a plurality of holes (not shown in the figure) are provided equidistantly along the axial direction on the reinforcing rib 135, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com