Mine hoist

A technology of mine hoist and braking mechanism, which is applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems of shortened life of steel wire rope, small bearing capacity, reduced flexibility, etc., so as to improve the friction coefficient and avoid stress concentration. , the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

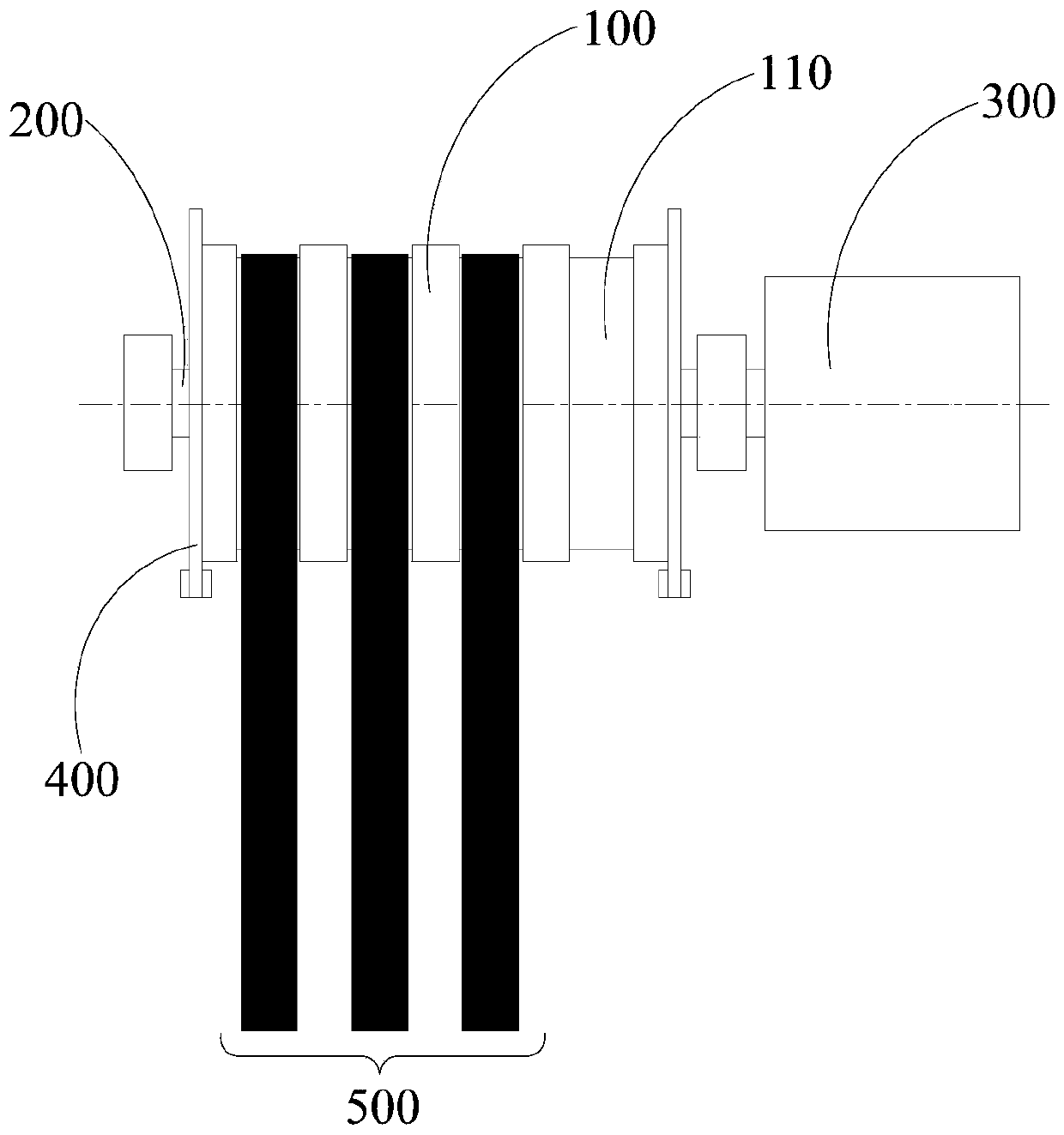

Embodiment 1

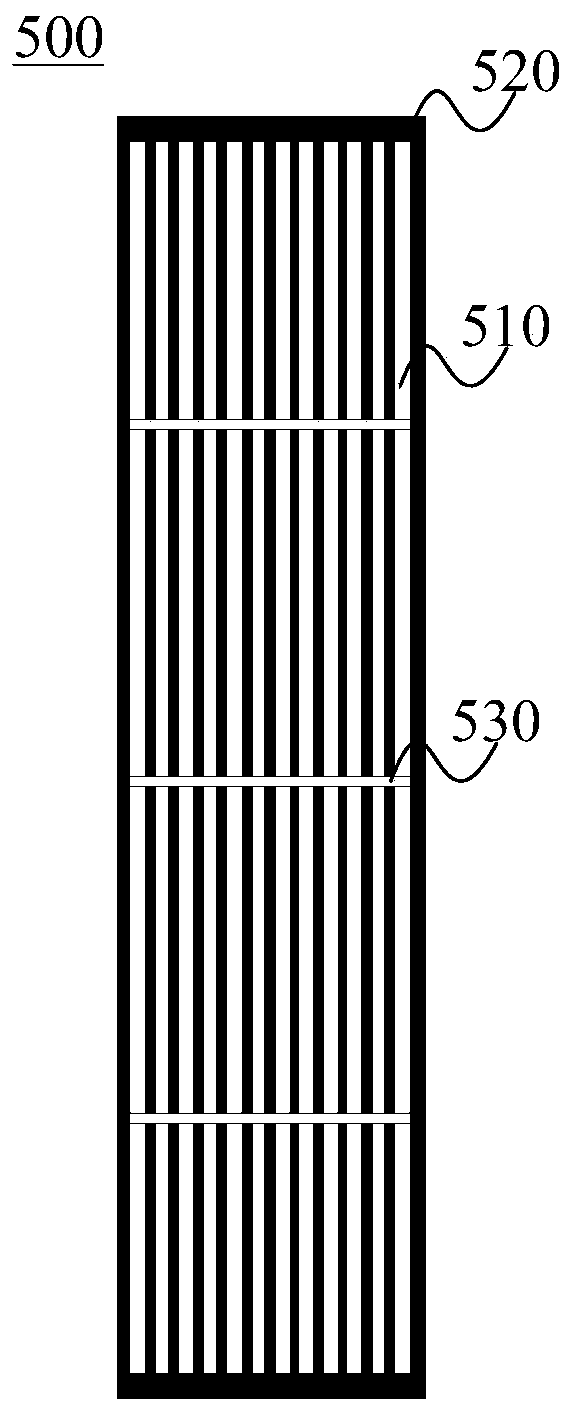

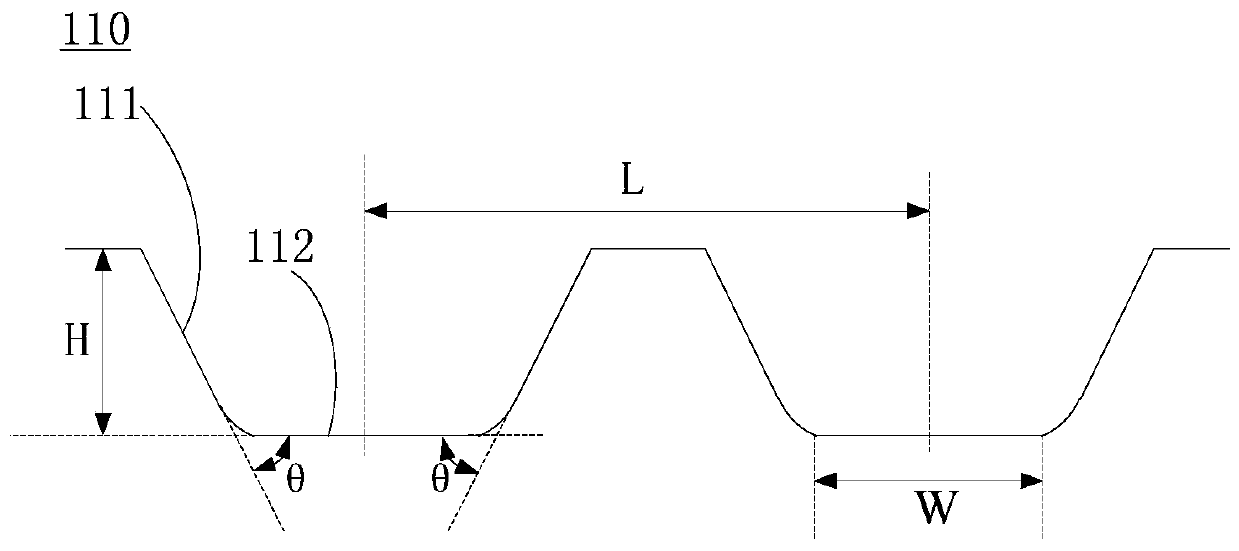

[0044] The lifting height is 1950m, the self-weight of the lifting container is 30t, and the normal load is 10t. A mine hoist with 6 limiting grooves and 6 lifting compound belts is used. The angle between the two sides and the bottom of the limiting groove is 110 degrees. The width of the bottom surface of the limiting groove is 233mm and the depth is 28mm. The section size of the hoisting composite belt is 230mm×28mm (width×thickness), the diameter of a single wire rope in the hoisting composite belt is 20mm, the diameter of the friction wheel of the mine hoist is 2.8m, and the width is 3.0m. No deviation occurred.

Embodiment 2

[0046] The lifting height is 1950m, the self-weight of the lifting container is 30t, and the normal load is 10t. A mine hoist with 6 limiting grooves and 6 lifting composite belts is used. The angle between the two sides and the bottom of the limiting groove is 110 degrees. The width of the bottom surface of the limiting groove is 203mm, and the depth is 24mm. The section size of the lifting composite belt is 200mm×24mm (width×thickness), the diameter of a single high-performance fiber rope in the lifting composite belt is 16mm, the diameter of the friction wheel of the mine hoist is 2.25m, and the width is 2.8m. There is no deviation phenomenon in the lifting composite belt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com