A water conservancy construction mud conveying device

A technology for construction mud and conveying device, which is applied in infrastructure engineering, construction and other directions, can solve problems such as handling difficulties, and achieve the effects of lightening the burden, reducing the volume and reducing the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

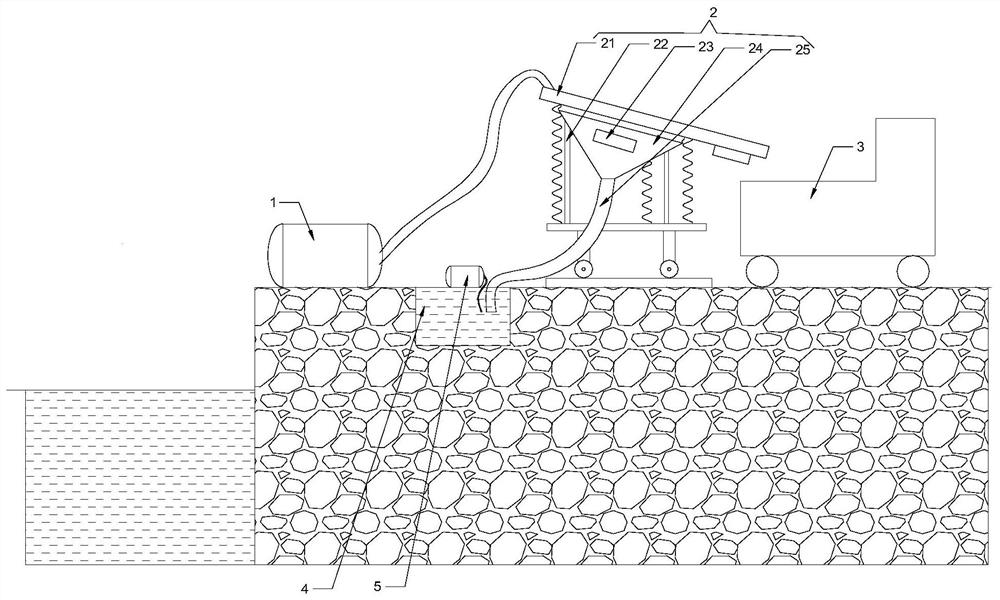

[0018] Such as figure 1 As shown, the present invention proposes a mud delivery device for water conservancy construction, comprising: a mud pump 1, whose input end is communicated with the mixture at the construction site; a separation device 2, which is communicated with the output end of the mud pump 1, and the separation device 2 is used to separate the mixture The medium mud is separated from the granular stones; the transfer vehicle 3 is used to catch and transfer the granular stones obtained by the separation equipment 2; the sedimentation tank 4 is arranged next to the construction site, and the sedimentation tank 4 catches the mud separated by the separation equipment 2; And the water pump 5, its input end communicates with the upper part of the sedimentation tank 4, and its output end communicates with the water source. First, the mud pump 1 pumps the granular stones produced by the mud into the separation device 2; then, the separation device 2 separates the mud fro...

Embodiment 2

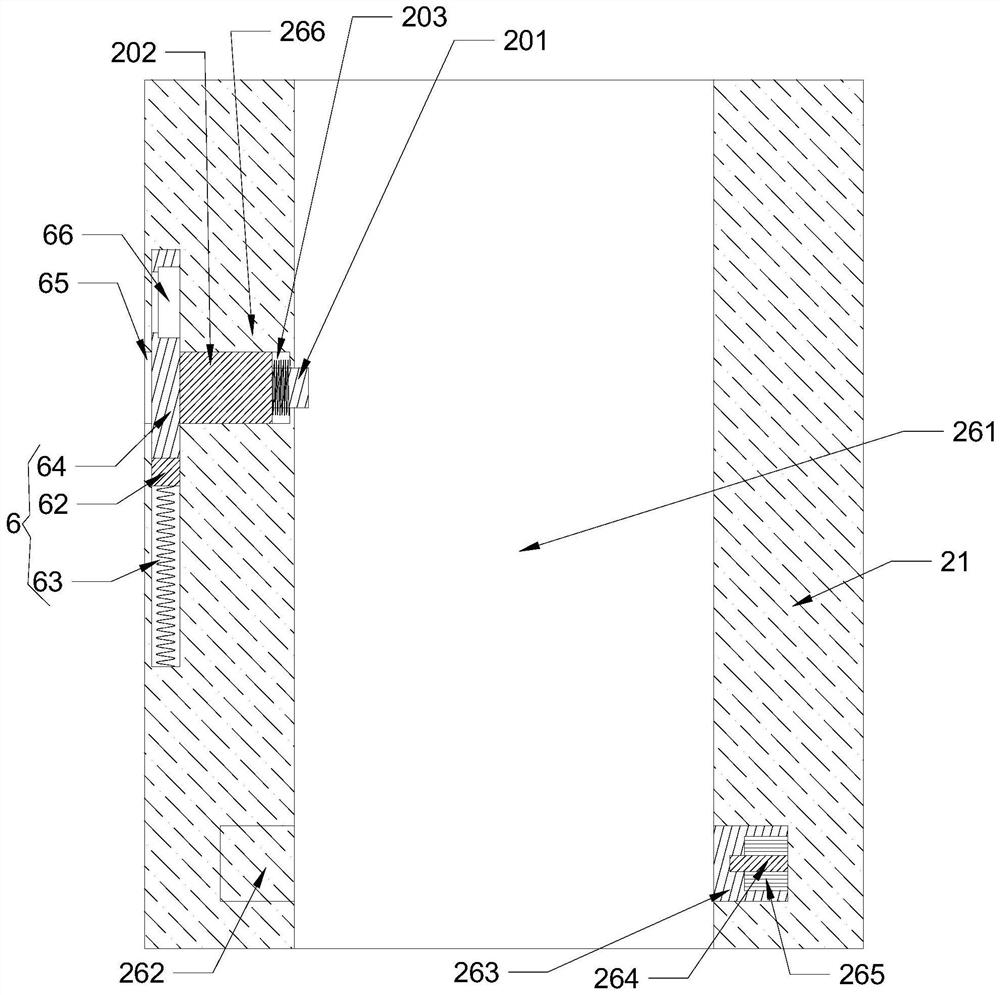

[0021] The difference between this embodiment and Embodiment 1 is: on the basis of Embodiment 1, the structure at the separation screen 21 is changed, and other structures remain unchanged.

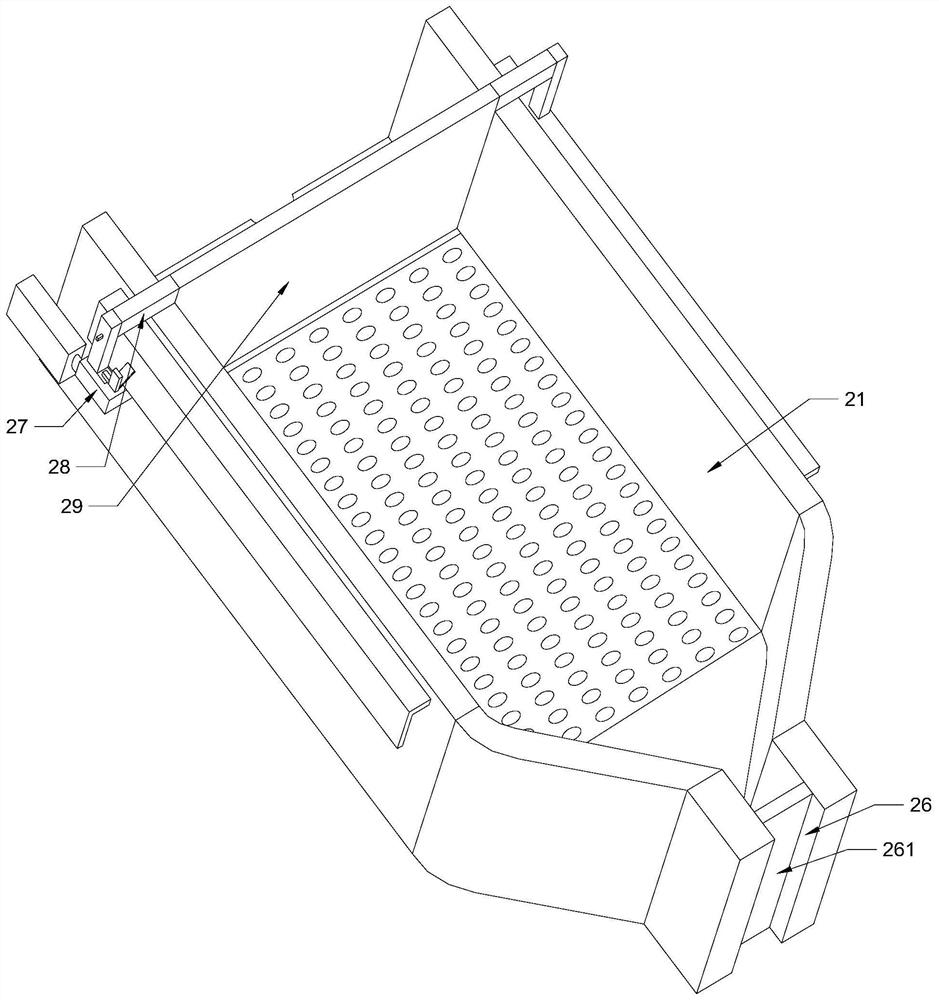

[0022] Such as Figure 2 to Figure 4 As shown, the separation screen 21 is equipped with an opening and closing assembly 26, and the opening and closing assembly 26 is used to open and close the bottom of the separation screen 21. After the tipping bucket of the transfer vehicle 3 is filled with granular stones, another empty transfer vehicle 3 needs to be replaced. If there are still granular stones discharged from the separation screen 21 at this time, the entire work site will be messy. Therefore, it is necessary to install an opening and closing assembly 26 to avoid the above. Phenomenon. When the transfer vehicle 3 is aligned with the bottom of the separation screen 21, the opening and closing assembly 26 opens the bottom of the separation screen 21; when the transfer vehicle 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com