Wire placing brick and low-heat-waste and high-heat-efficiency electric heating structure

A high thermal efficiency technology for wire bricks, applied in the fields of wire bricks, high thermal efficiency electric heating structures, wire bricks and low heat loss, can solve the problems of large heat loss of heating devices, large heat storage of furnace walls, and short service life. Achieve the effects of high thermal efficiency, small heat storage in the furnace wall and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

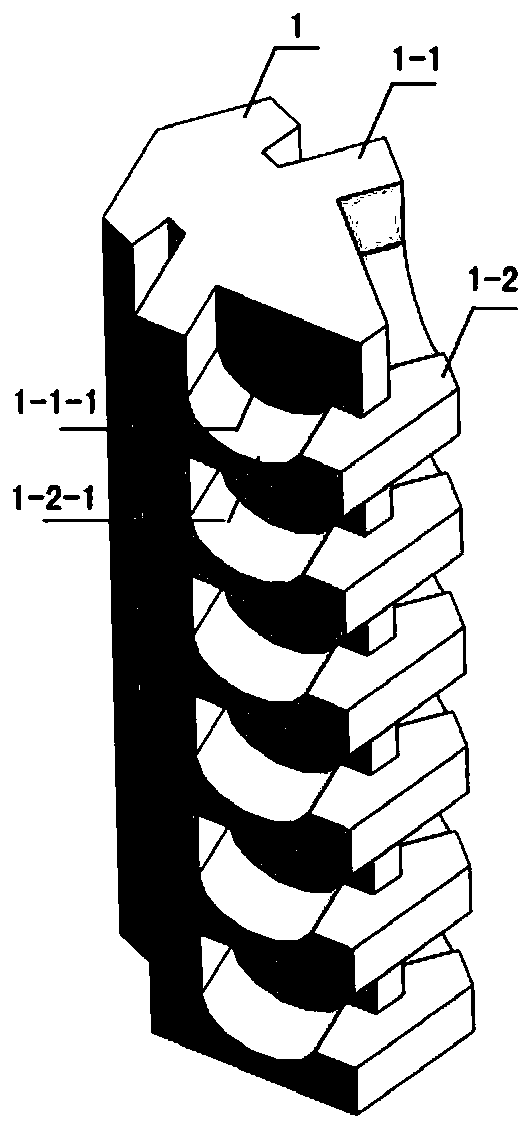

[0027] refer to figure 1 , the threaded brick involved in this embodiment 1 includes a brick body 1, the upper part 1-1 of the brick body 1 has an approximate "T" shape structure, the bottom is a platform structure 1-2, and the platform structure 1-2 An upward arc-shaped groove 1-2-1 is provided on both sides, and a downward arc-shaped groove 1-1-1 is respectively provided on both sides of the bottom surface of the upper part 1-1 of the brick body 1, forming a space for installing electric heating devices from both sides. Structure; the projected area of the upper part 1-1 of the brick body 1 is relatively small, forming an easy-to-embed and take-out structure of the electric heating device. A three-dimensional wire brick structure can be formed by stacking several wire bricks.

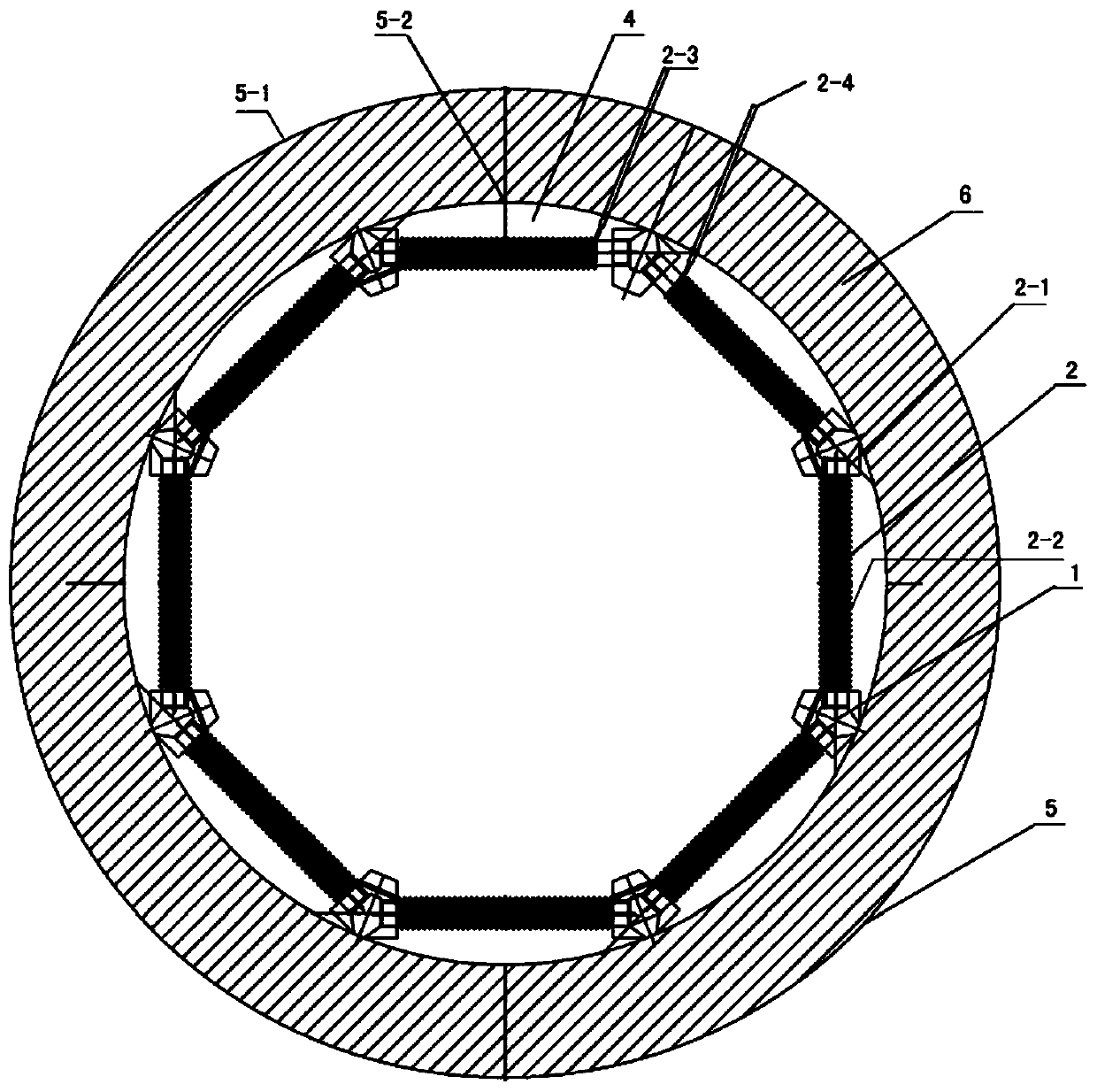

[0028] refer to figure 2 The electric heating structure with low heat loss and high thermal efficiency involved in this embodiment 1 includes several wire bricks, the upper part 1-1 of the brick ...

specific Embodiment 2

[0038] The feature of this specific embodiment 2 is: in the polygonal structure connected by the electric heating device 2, it includes a triangular structure, a quadrilateral structure, a pentagonal structure, a hexagonal structure, a decagonal structure or more than twelve according to the size of the inner wall. polygonal structure. All the other are with specific embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap