Device and method for testing flow velocity of composite solid propellant slurry

A solid propellant and testing device technology, which is applied in the characterization of the propellant slurry flow rate and the device field of the propellant slurry flow rate, can solve problems such as low test accuracy, eliminate potential safety hazards, facilitate sample injection and sample cleaning, Accurate data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

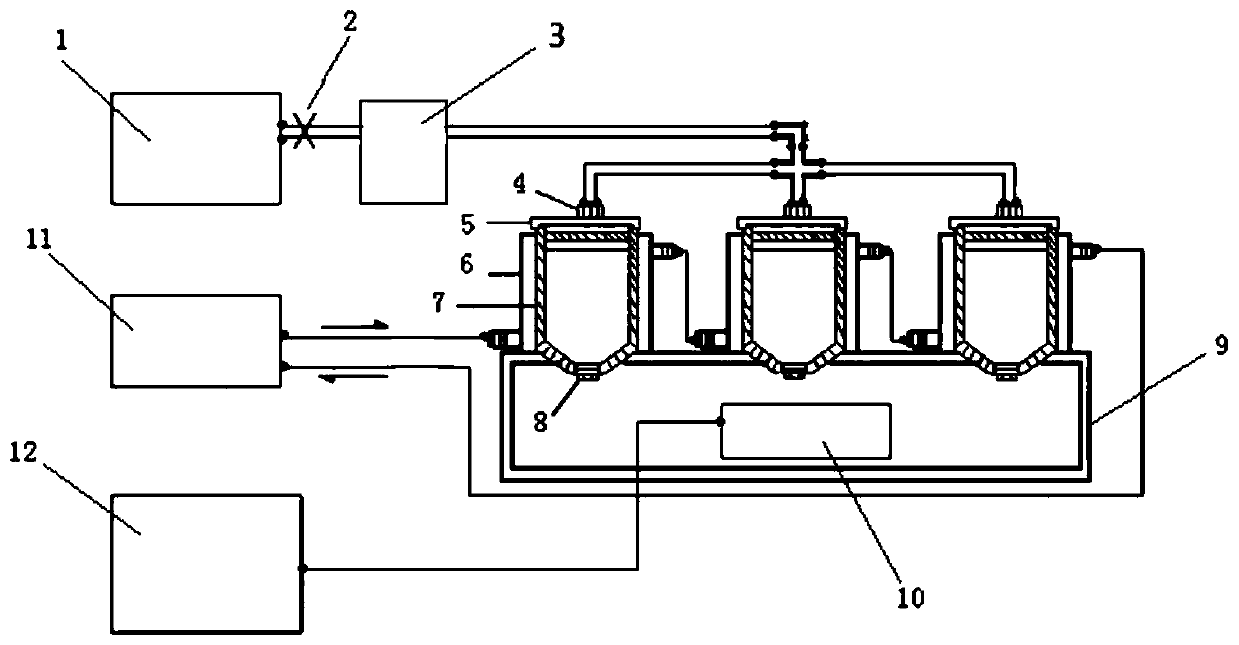

[0041] This embodiment is a propellant slurry flow rate testing device under pressurized conditions, including a pressure generator 1, a pressure transmitter 3, a heat preservation jacket 6, three viscosity cups 7, a viscosity cup bracket 9, an electronic balance 10, Constant temperature water bath box 11 and computer 12, wherein:

[0042] The three viscosity cups 7 are respectively the first viscosity cup, the second viscosity cup and the third viscosity cup; the first viscosity cup, the second viscosity cup and the third viscosity cup are all placed on the viscosity cup support 9 . There are three thermal insulation jackets 6, which are respectively set on the shells of the viscosity cups to form the first thermal insulation jacket of the viscosity cup, the second thermal insulation jacket of the viscosity cup and the third thermal insulation jacket of the viscosity cup. There is a distance of 1 mm between the inner surface of each of the thermal insulation jackets and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com