Gradient background digital X-ray image defect automatic identification method

An automatic identification and X-ray technology, applied in image enhancement, image analysis, image data processing, etc., to achieve high recognition efficiency, improve signal-to-noise ratio, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0049] A digital X-ray image defect automatic identification method with gradient background, comprising the following steps:

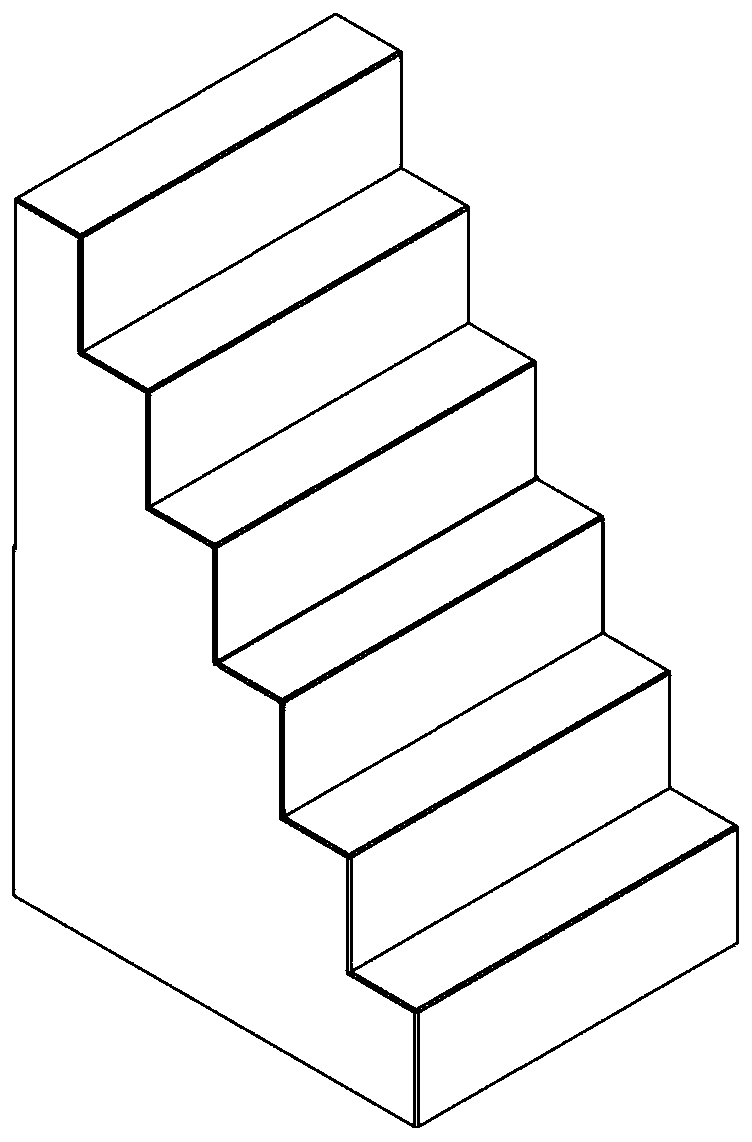

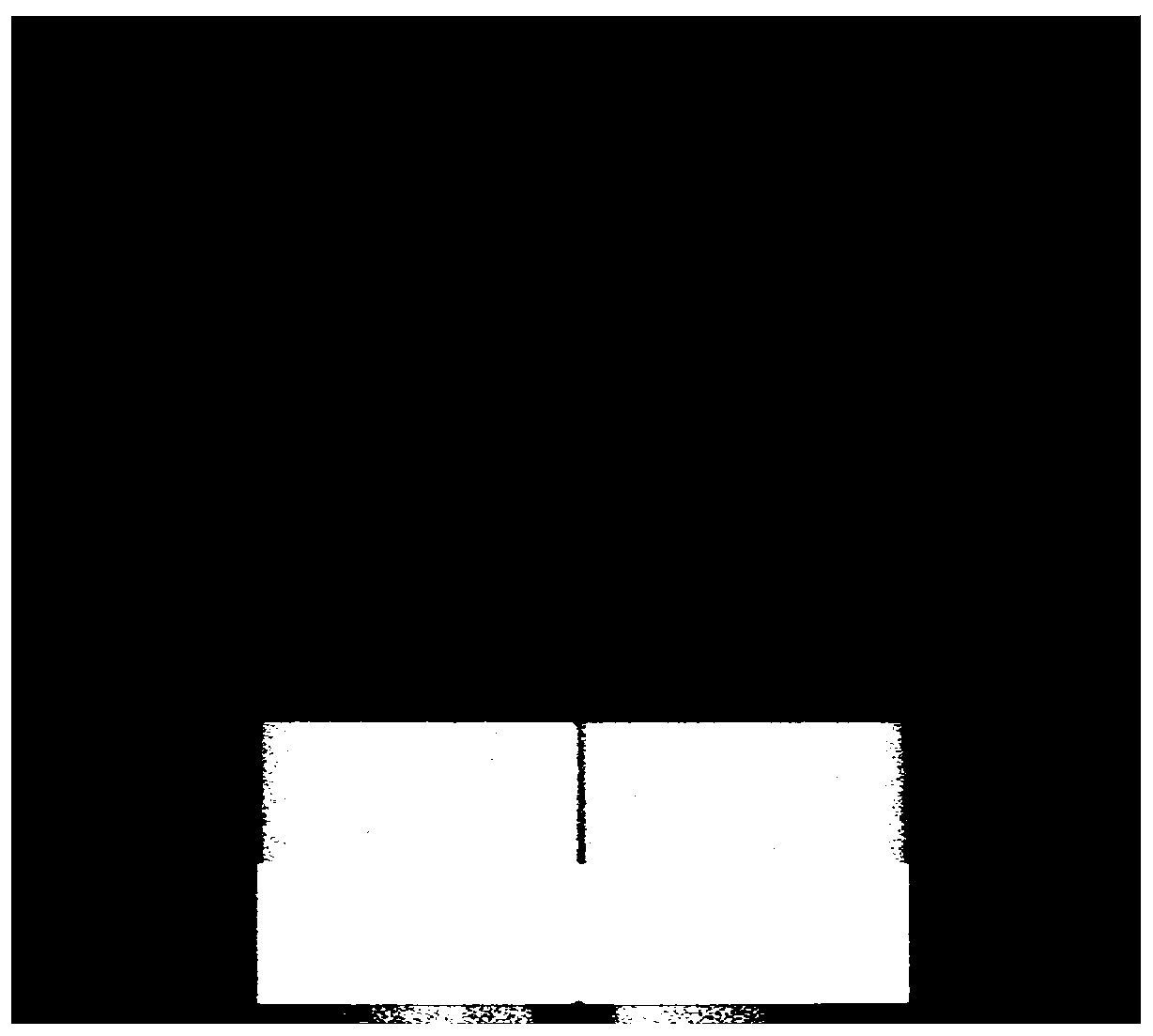

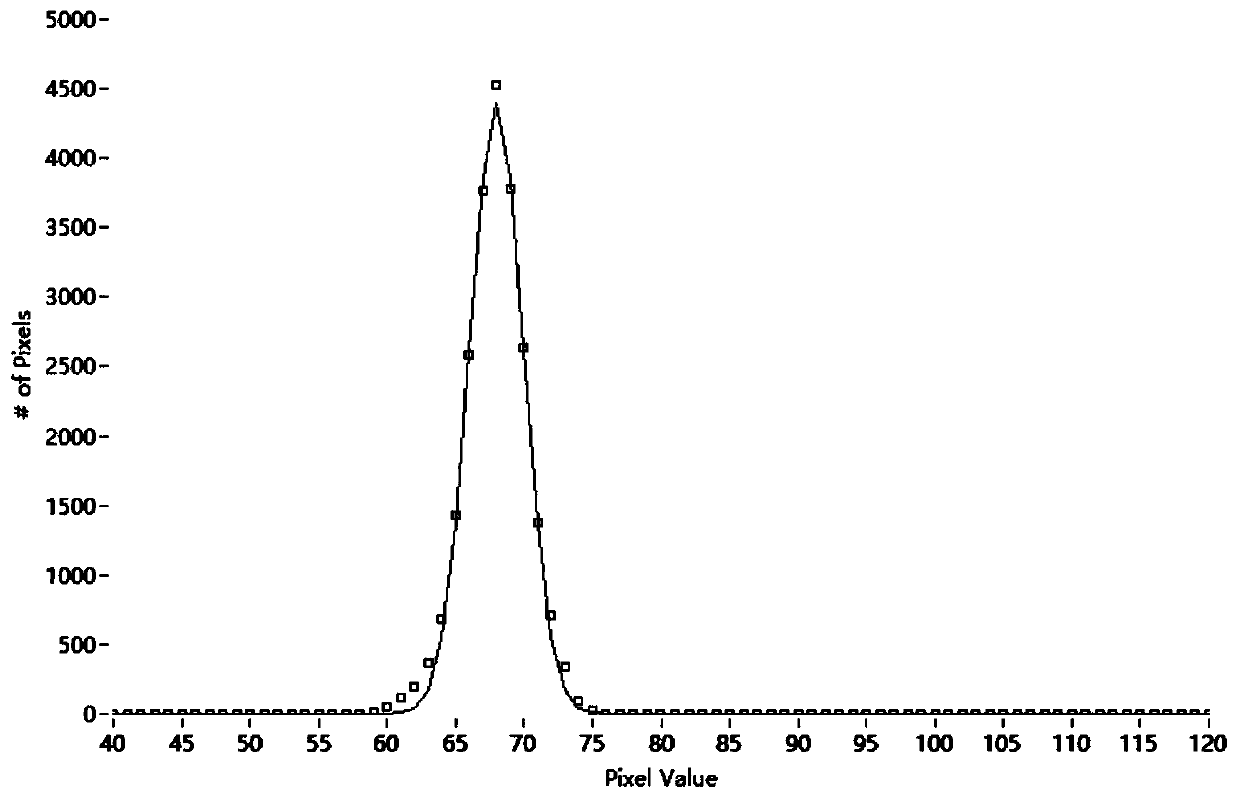

[0050] Step 1. Manufacture a ladder-shaped comparison test block that is consistent with the material of the workpiece to be inspected by mechanical processing, and the thickness of each step of the comparison test block changes gradually, wherein the maximum thickness of the comparison test block is greater than or equal to the thickness of the workpiece to be inspected The maximum thickness and the minimum thickness are less than or equal to the minimum thickness of the inspected workpiece; the number of steps of the comparison test block is greater than or equal to 5. In this embodiment, a gradient background is formed after DR scanning through the gradually changing ladder-shaped inspected workpiece and the compari...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap