Plant factory adopting double-rotation mist spray planting

An aerosol cultivation and double-rotation technology, applied in greenhouse cultivation, botany equipment and methods, climate change adaptation, etc., can solve the problems of unfavorable plant factory industrial production and promotion, low production efficiency, and unsatisfactory overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

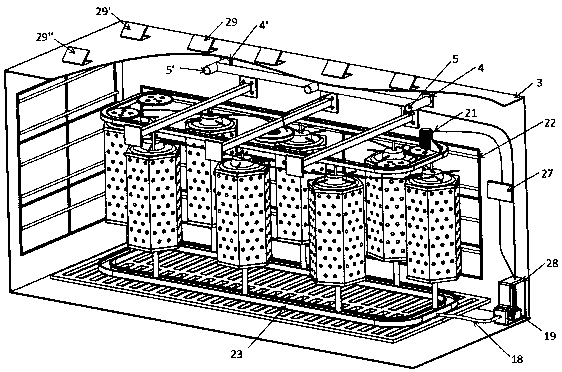

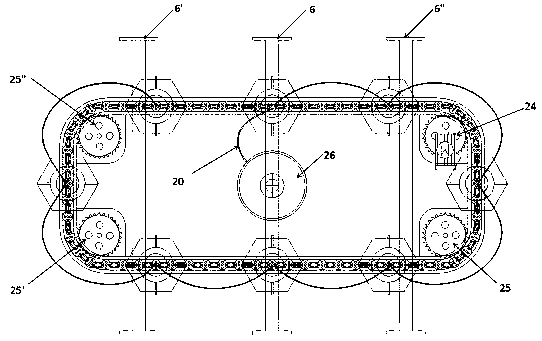

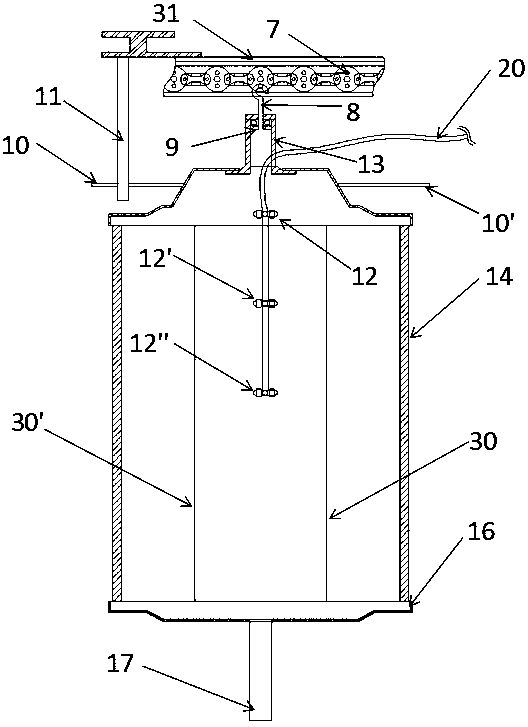

[0028] A double-rotation aerosol cultivation plant factory, which includes a box-type main body 3, and the box-type main body 3 is provided with supporting frames 6, 6', 6", a cultivation main body, a rotating device, a nutrient solution circulation device, and a supplementary light Device 22, ventilation device and electrical control device 27, the cultivation main body includes an upper cover 15, a planting bucket body 14, a lower cover 16 and connecting screw rods 30, 30', and the rotating device includes a hook 8 and a rotating bearing 9 , bearing mount 13, drive motor 21, driving wheel 24, driven wheel 25, 25 ', 25 ", chain 7 and chain track 31, described nutrient solution circulation device comprises liquid storage tank 28, water pump 19, water inlet pipe 20, Liquid supply turntable 26, return pipe 17, water collection tank 23, centralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com