Rose syrup and preparation method thereof

A technology of rose syrup and rose puree, applied in confectionery, confectionery industry, and the function of food ingredients, etc., can solve the problem of fructose syrup such as apple syrup, strawberry syrup, banana syrup, kiwifruit syrup, and mango syrup that has not been reported in the literature. Syrup, glucose syrup, etc., as well as nut syrups such as caramel syrup, coffee syrup, toffee syrup, chocolate syrup, etc., to achieve stable product quality, maintain unique aroma and rose pigment, and round and full taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

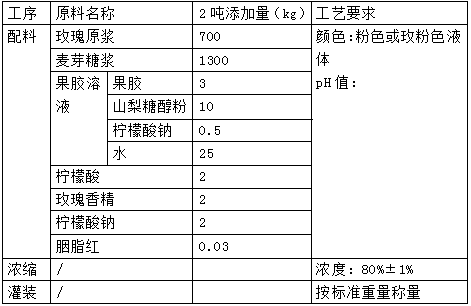

[0030] The raw material application of rose syrup is shown in the table below:

[0031]

[0032] Concrete preparation steps are as follows:

[0033] (1) Preparation of rose puree: 2 parts (both parts by weight) of double roses are mixed with 4 parts of maltose, 2 parts of white sugar and 1.0 part of water, stirred and beaten to obtain rose pulp; add citric acid to Incubate the rose pulp at 70°C for 7 days, then cool down to obtain the rose puree;

[0034] (2) Feeding: First add about 2 / 3 of maltose syrup into the batching tank, heat up and stir to 60°C-70°C, add rose puree and carmine pigment successively, continue stirring and heat to 90°C-95°C;

[0035] (3) Add pectin: fully mix the pre-weighed pectin, sorbitol powder, and sodium citrate in a clean container, stir and dissolve with water at 20°C±10°C to ensure that the pectin solution has no clot. When adding, pay attention to rinse the container with a small amount of water to ensure that all the pectin solution is ad...

Embodiment 2

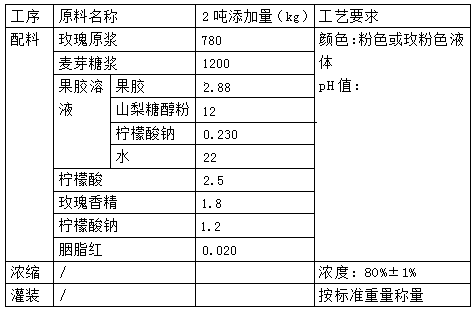

[0040] The raw material application of rose syrup is shown in the table below:

[0041]

[0042] Concrete preparation steps are as follows:

[0043] (1) Preparation of rose puree: 3 parts (both parts by weight) of double-petal roses are mixed with 8 parts of maltose, 4 parts of white sugar, and 3 parts of water, stirred, and beaten to obtain rose pulp; add citric acid to Incubate the rose pulp at 50°C for 15 days, then cool down to obtain the rose puree;

[0044] Steps (2)-(6) are as in Example 1.

Embodiment 3

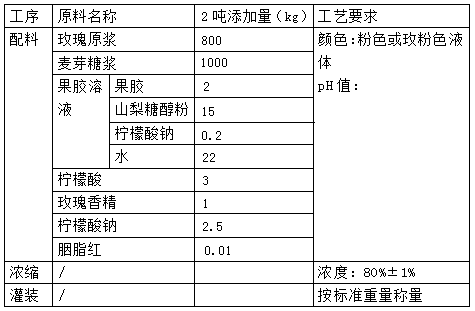

[0046] The application of rose syrup raw materials is shown in the table below:

[0047]

[0048] Concrete preparation steps are as follows:

[0049] (1) Preparation of rose puree: 2.5 parts (both parts by weight) of double-petal roses are mixed with 6 parts of maltose, 3 parts of white sugar, and 2 parts of water, stirred, and beaten to obtain rose pulp; add citric acid to Incubate the rose pulp at 60°C for 10 days, then cool down to obtain the rose puree;

[0050] Steps (2)-(6) are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com