A differentiated fine beneficiation host

A differentiated, host technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc., can solve the problem of inability to finely classify mineral powders, and achieve the effect of less dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

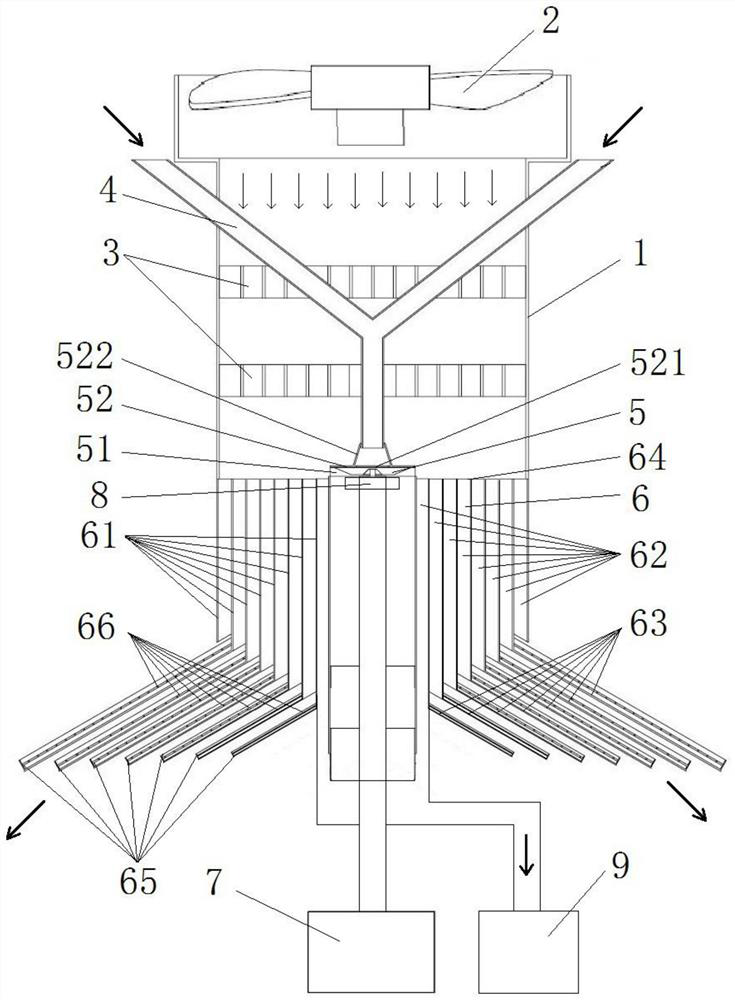

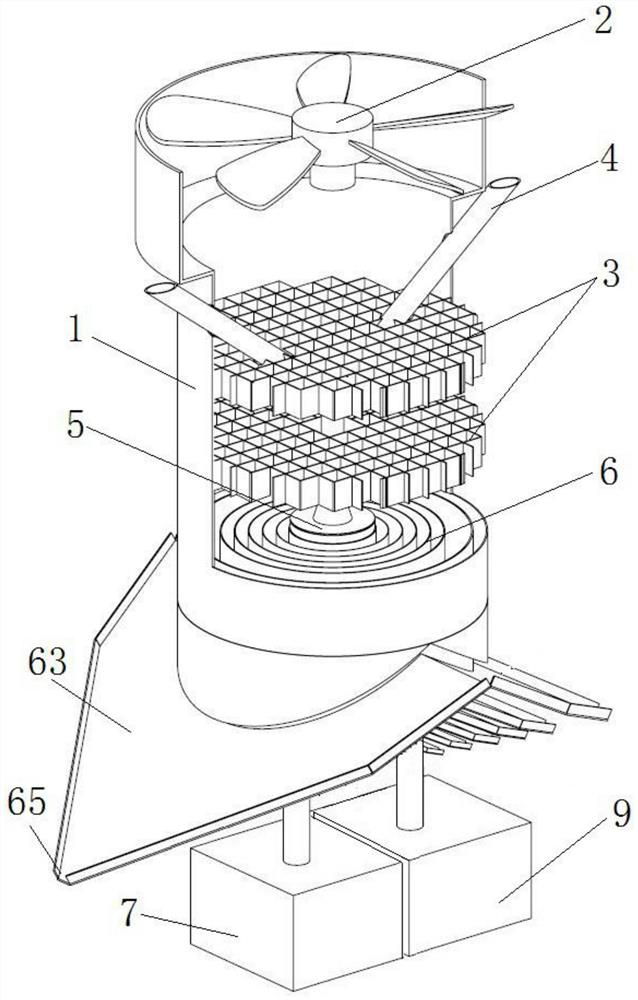

[0032] like figure 1 and figure 2 As shown, a differentiated fine mineral processing host includes: a cylindrical host sleeve 1 with a diameter of 1200mm; a fan 2 parallel to the cross-section of the host sleeve 1 is installed above the cylindrical host sleeve 1, and the fan 2 is located The diameter of the shaft section of the main engine sleeve 1 is 1300mm, and the power of the fan 2 is 1.5kW.

[0033] Two rectifying discs 3 parallel to the fan 2 are also installed inside the host sleeve 1 , and the rectifying discs 3 are a grid-like structure composed of several cross-sectional thin plates perpendicular to the host sleeve 1 . The thin plate is perpendicular to the section of the host sleeve 1, the grid is a square, the side length is 10cm, and the thin plate width is 10cm. There is a hole in the middle part of the rectifying plate 3, and the feeding pipeline 4 can pass through the circular hole.

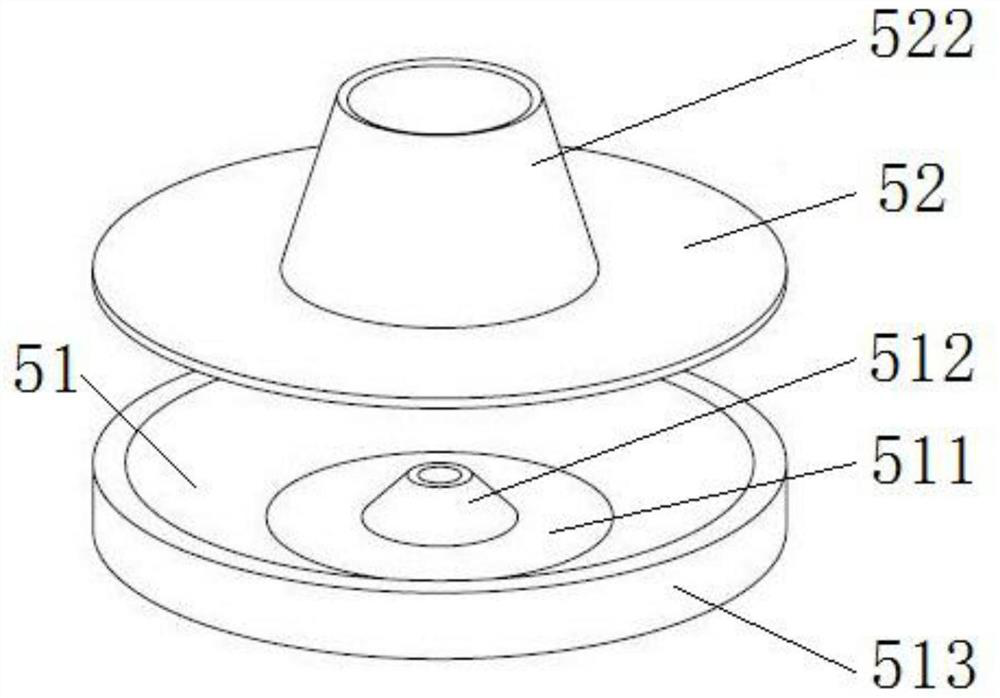

[0034] The feeding end of the feeding pipe 4 is set under the fan 2, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com