Titanium alloy foil miniature piece ultrasonic vibration rubber forming device and forming method

A technology of titanium alloy foil and ultrasonic vibration, which is applied in the field of ultrasonic vibration rubber forming devices for titanium alloy foil micro-parts, can solve the problems of foil forming wrinkling, cracking, springback, etc., and achieves small forming resistance, reduced springback, The effect of high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

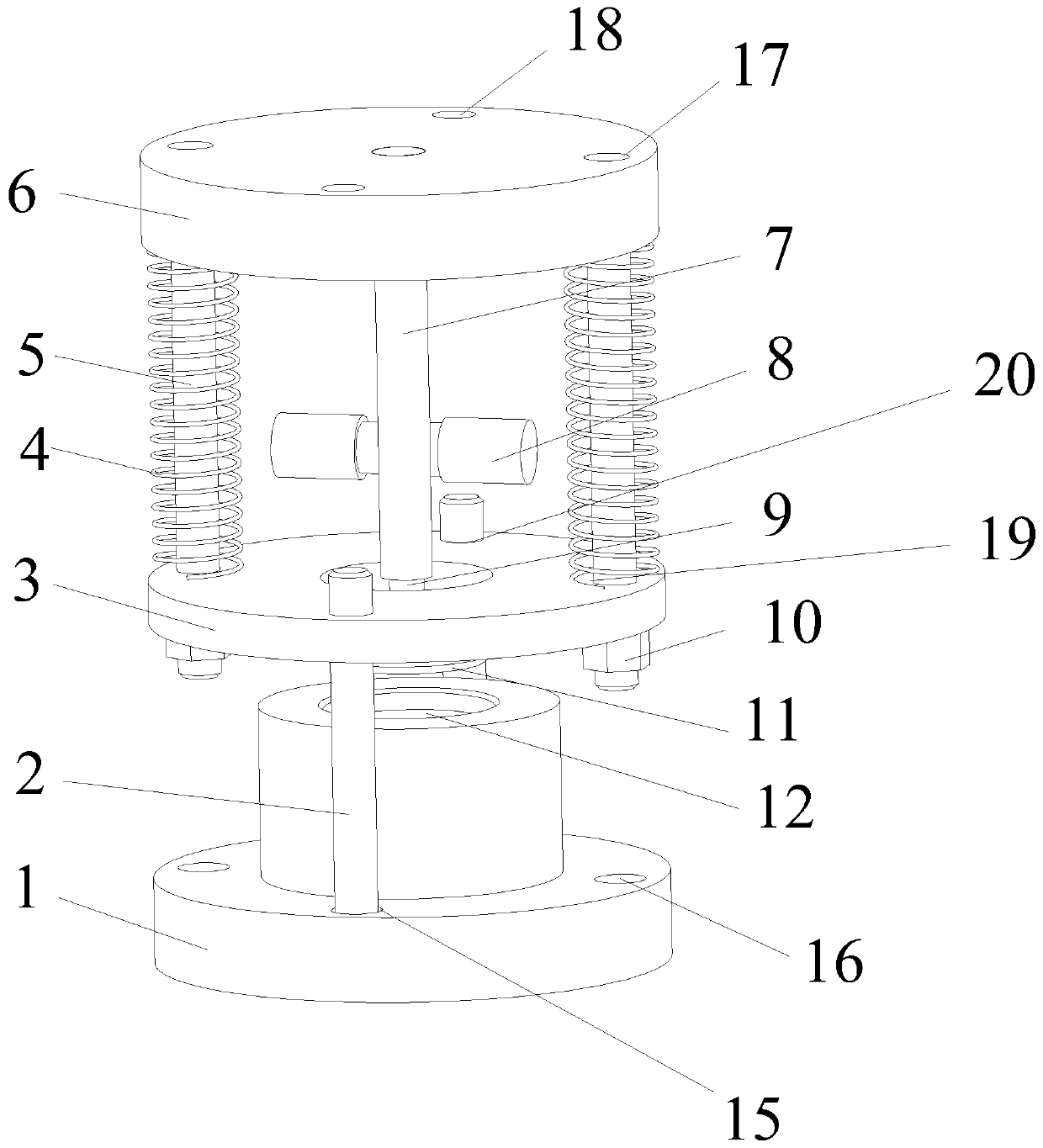

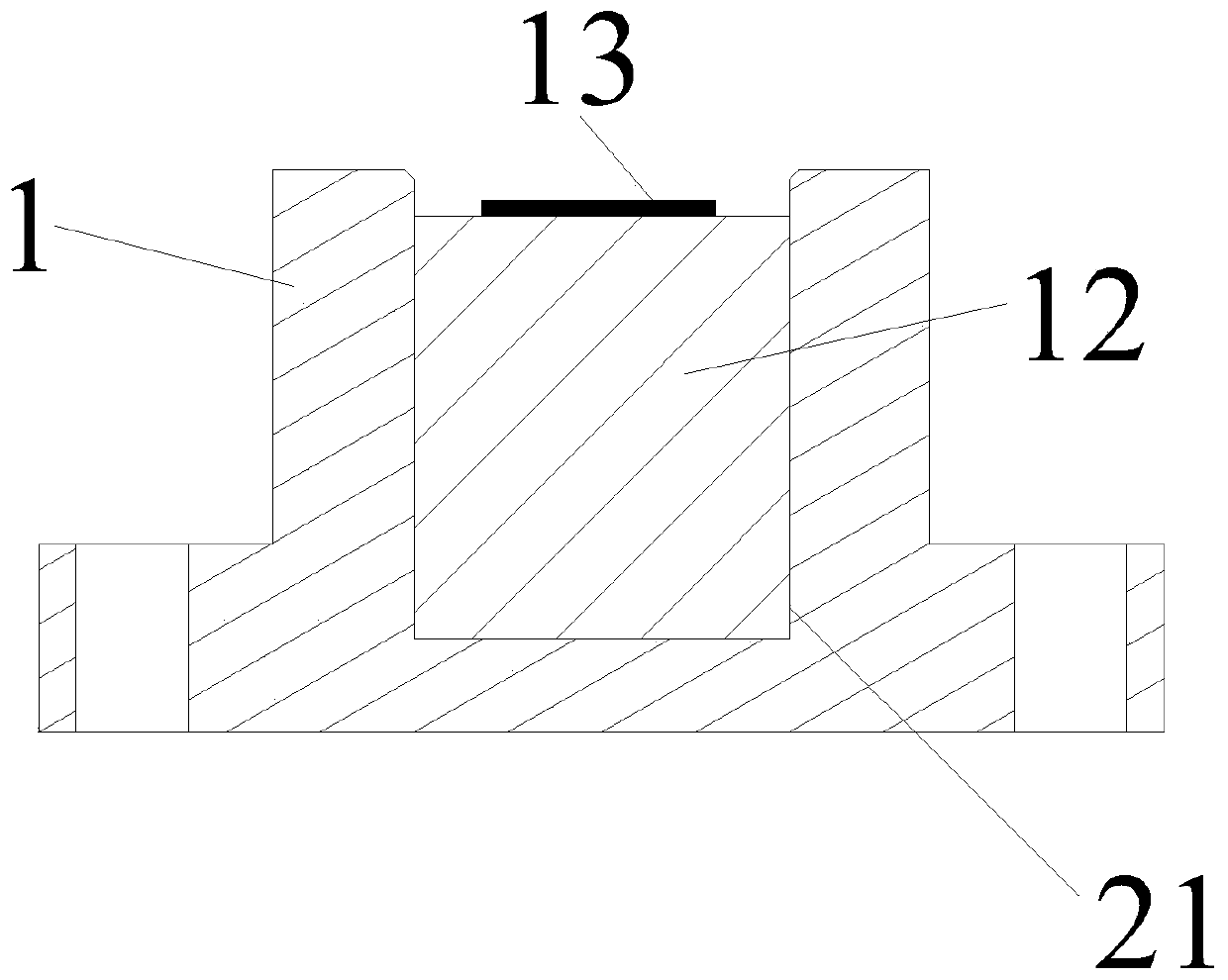

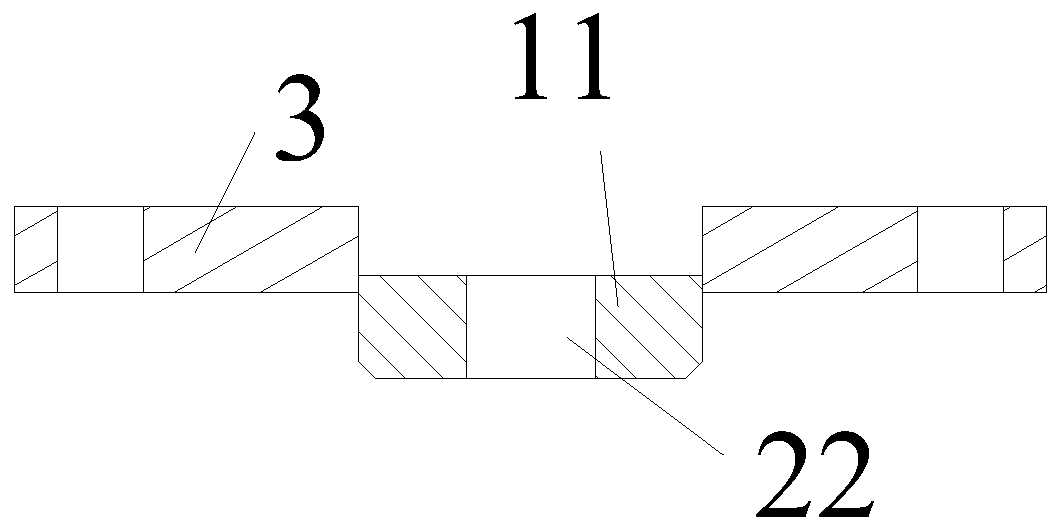

[0024] like figure 1 , 2, 4, 5, a titanium alloy foil micro-part ultrasonic vibration rubber forming device, including a die 1, a punch 9, a top plate 6 and a blank holder 11, the die 1 is provided with a first connection hole 15, The outer edge of the blank holder 11 is provided with a connecting plate 3, and the connecting plate 3 is provided with a third connecting hole 20 that matches with the first connecting hole 15. The connecting plate 3 and the die 1 pass through the first connection. The hole 15 is connected with the guide rod 2 of the third connecting hole 20. One end of the guide rod 2 is fixed on the die 1, and the other end of the guide rod 2 is slidably connected with the connecting plate 3. The guide rod 2 can play the role of guiding and positioning. The connecting plate 3 can slide up and down along the guide rod 2, the top plate 6 is provided with a second connecting hole 17, the connecting plate 3 is provided with a fourth connecting hole 19 matched with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com