Boring tool used for machining small-hole-diameter step type round hole inner cavity and provided with replaceable tool head

A technology of small aperture and cutter head, which is applied in the direction of tools, manufacturing tools, metal processing equipment, etc. for lathes, can solve the problems of low processing efficiency, easy deviation of processing concentricity, etc., so as to improve processing efficiency and processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

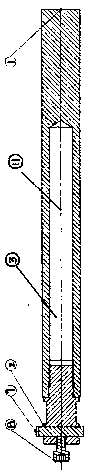

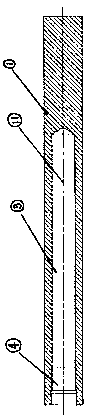

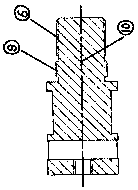

[0015] A boring tool with a replaceable cutter head for processing the inner cavity of a circular hole with a small diameter and a step, including a cutter rod (1) and a cutter head seat (2), and a barrel-shaped cavity is arranged on the cutter rod (1) (3), the cavity mouth (4) of the barrel-shaped cavity (3) is connected with a cutter head seat (2), and the cutter head seat (2) is respectively provided with connecting threads (6) for the cutter head and the cutter bar And the annular positioning step (9), the cutter head seat (2) is screwed in the cavity mouth (4) through the connecting thread (6) of the cutter head and the cutter rod, and the central axis (10) of the annular positioning step (9) It coincides with the central axis (11) of the cutter bar (1), and the blade (7) is fixed on the cutter head seat (2) through the top wire (8); when processing the hole-shaped inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com