Special device for rough and finish turning of gas turbine bearing base

A technology for gas turbines and special devices, which is used in positioning devices, supports, metal processing mechanical parts, etc., can solve the problems of difficulty in ensuring the accuracy of workpieces, difficult alignment of bearing seats, poor machining accuracy of inner diameters, etc., so as to improve the processing quality. and processing efficiency, reducing the time of clamping and alignment, and the effect of simple tooling production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

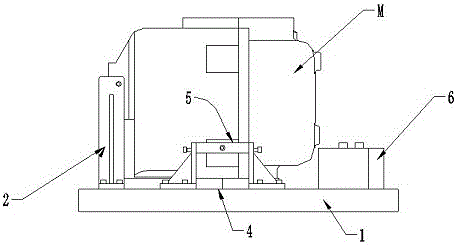

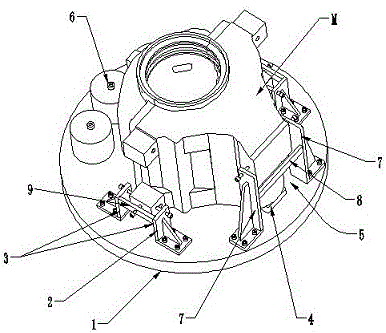

[0030] Examples such as Figure 1-3 As shown, the special device for rough and fine turning of gas turbine bearing seat includes base 1, facing pressure plate 2, side pressure plate 5, contour block 4, counterweight block 6 and hexagon socket bolts.

[0031] The base 1 provides a platform for the bearing seat M to be processed and the tooling. It is rigid enough to reduce the deformation of the bearing seat M to be processed; Find the correct efficiency.

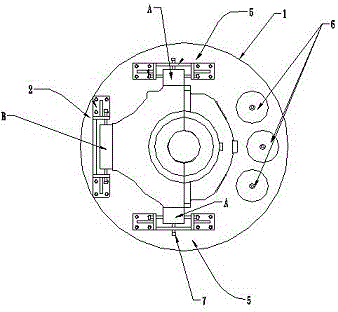

[0032] The base 1 is a disk-shaped base, and the side pressure plate 5 is fixedly connected to the position of the disk surface of the base 1 near the outer edge of the disk surface. The number of the side pressure plates 5 is two, and the two side pressure plates 5 are arranged symmetrically along the axis of the base 1.

[0033] Each side pressure plate 5 includes two oppositely arranged first right-angle pressure plates 7, a first transverse pressure plate 8 is fixedly connected between the two first right-angle pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com