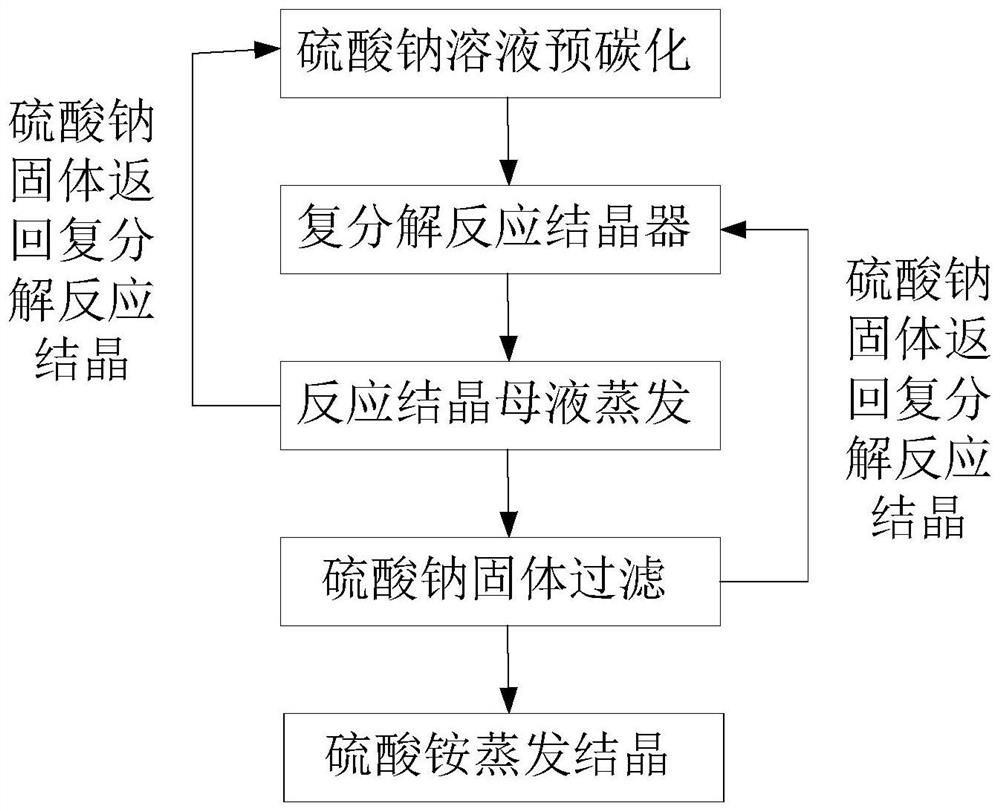

Sodium desulfurization ash resourceful treatment system and treatment method

A desulfurization ash and treatment system technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of high market price of sodium bicarbonate, resource waste environment, accumulation of mirabilite ash and slag, etc., and achieve good economy value, reduce environmental pollution, and increase the effect of total nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

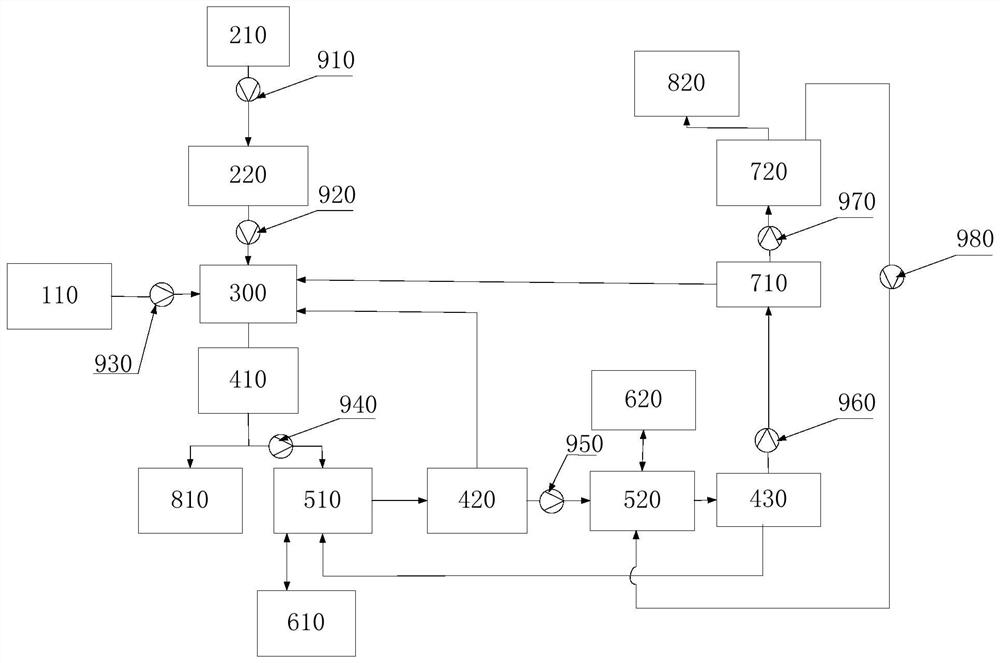

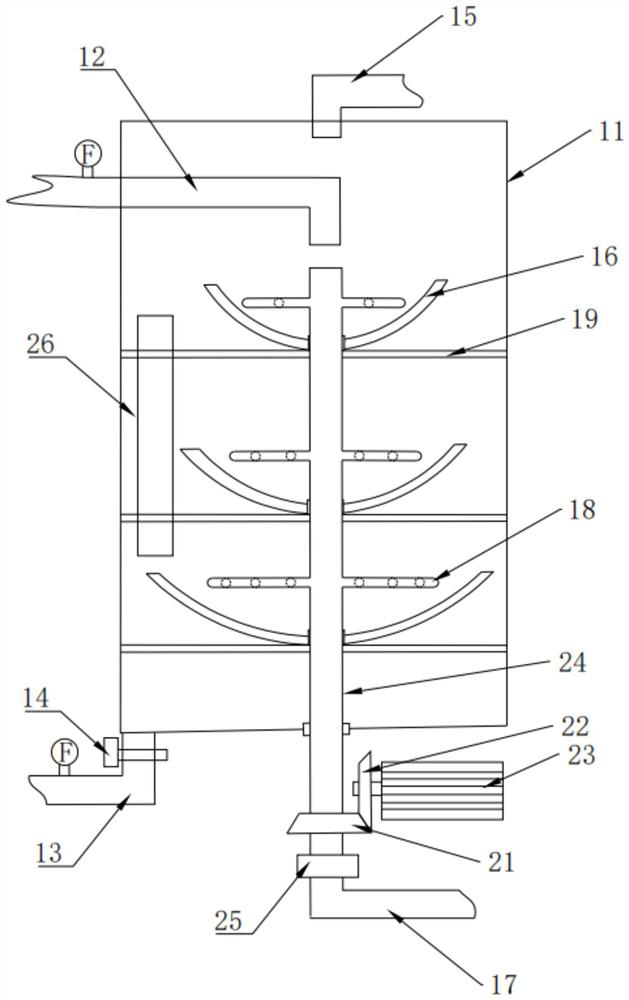

[0034] A sodium desulfurization ash resource treatment system, such as figure 2 As shown, it includes ash slag pretreatment device, ammonium bicarbonate preparation device 100 and metathesis reactor 300, primary cooling crystallizer 510, secondary cooling crystallizer 520, ammonia distillation tower 710 and evaporative crystallization device 720, the discharge port of the ash pretreatment device and the discharge port of the ammonium bicarbonate preparation device 100 are communicated with the feed port of the metathesis reactor 300 through pipelines respectively, and the liquid outlet of the metathesis reactor 300 is connected to the The feed port of the primary cooling crystallizer 510 is connected, the liquid outlet of the primary cooling crystallizer 510 is connected with the liquid inlet of the ammonia distillation tower 710, and the liquid outlet of the ammonia distillation tower 710 is connected with the inlet of the secondary cooling crystallizer 520. The feed port is...

specific Embodiment 2

[0080] The same place in this embodiment and specific embodiment 1 will not be repeated, and the difference is:

[0081] In the treatment method, the conditions for primary cooling and crystallization are as follows: cooling with ammonia to 10~-5°C, precipitation of sodium sulfate / ammonium bicarbonate double salt, centrifugal filtration, the obtained solid sodium sulfate / ammonium bicarbonate double salt returns to double decomposition In the reaction, the solution of the separated sodium sulfate / ammonium bicarbonate double salt is the primary cooling mother liquor.

[0082] Specifically, the conditions for secondary cooling and crystallization are as follows: cooling with ammonia to 10-5°C, depositing sodium sulfate / ammonium bicarbonate double salt, centrifugal filtration, and adding the obtained solid sodium sulfate / ammonium bicarbonate double salt to step S2 In the middle reaction mother liquor and with the reaction mother liquor for primary cooling and crystallization, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com