Self-cleaning type aeration tank used for processing building sewage

A self-cleaning and aeration tank technology, applied in water aeration, special treatment targets, sustainable biological treatment, etc., can solve problems such as inconvenience in cleaning, and achieve the effect of facilitating cleaning, solving inconvenience in cleaning, and improving aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

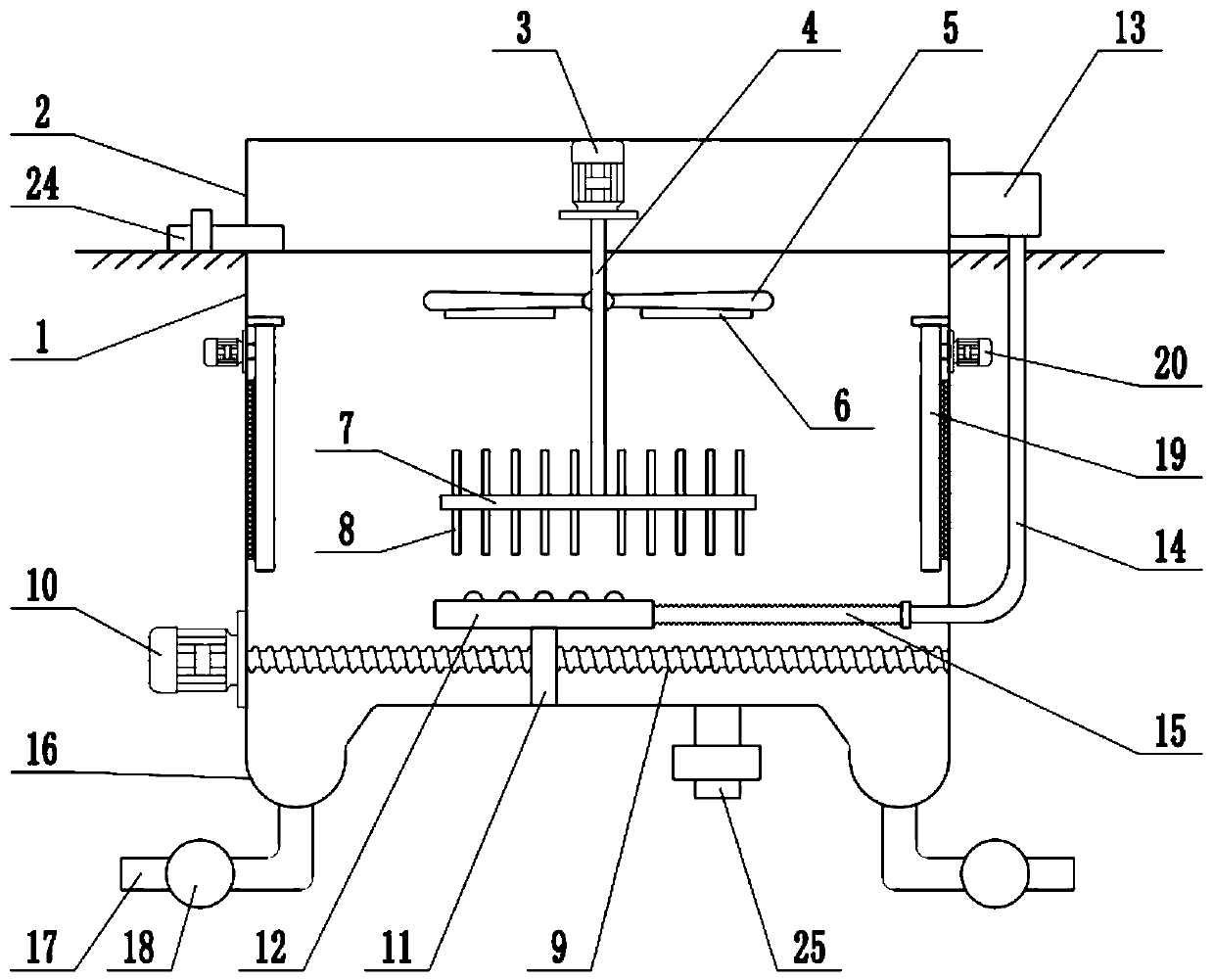

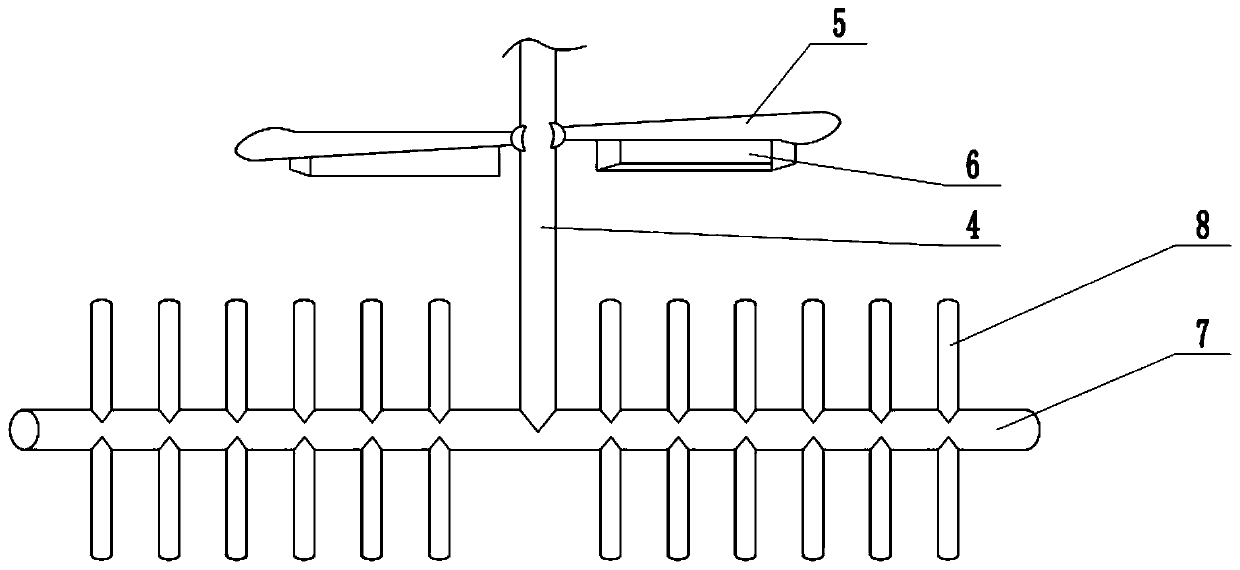

[0022] see Figure 1-3 , in an embodiment of the present invention, a self-cleaning aeration tank for treating construction sewage includes a tank body 1, a fixed frame 2 and an aeration disc 12, the top of the tank body 1 is fixedly connected with a fixed frame 2, and the fixed frame The top of 2 is fixedly connected with an aeration motor 3, and the shaft extension end of the aeration motor 3 is fixedly connected with a rotating shaft 4, and the lower end of the rotating shaft 4 extends into the pool body 1, and the surface aeration mechanism is installed on the rotating shaft 4, Including aeration blade 5 and buoyancy tank 6, aeration blade 5 is hinged to rotating shaft 4, buoyancy tank 6 is fixedly connected to the lower surface of aeration blade 5, utilizes buoyancy tank 6 to make aeration blade 5 always float on the surface of sewage, aeration When the air motor 3 is running, it drives the rotating shaft 4 to rotate, and then drives the aeration blade 5 to rotate, and th...

Embodiment 2

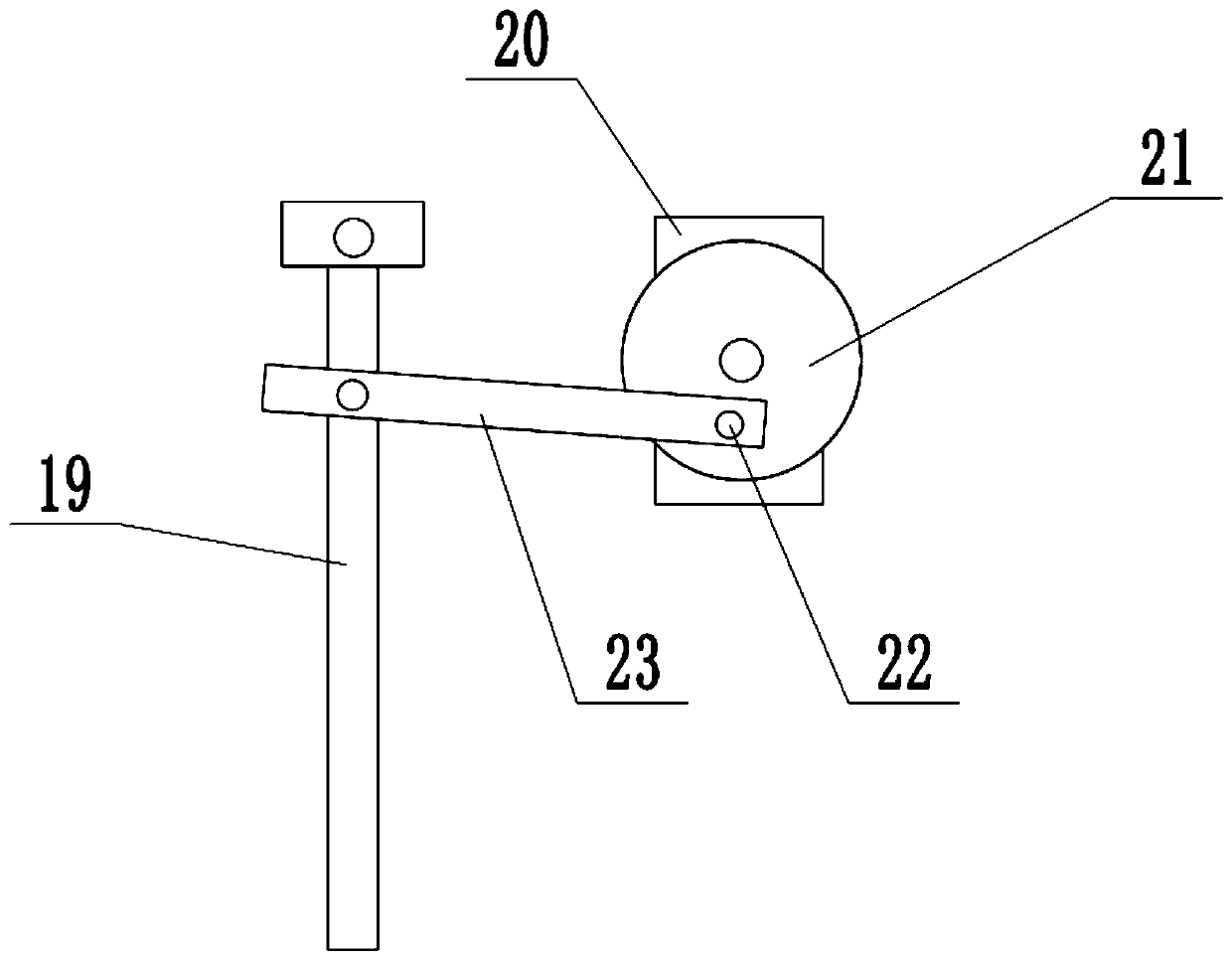

[0026] On the basis of Embodiment 1, a side wall cleaning mechanism is installed on the inner side wall of the pool body 1, and the side wall cleaning mechanism includes a cleaning brush 19, a side wall cleaning motor 20, a rotating disk 21 and a connecting rod 23, and the end of the cleaning brush 19 Rotately connected with the inner side wall of the pool body 1, bristles are distributed on the cleaning brush 19, the bristles abut against the inner side wall of the pool body 1, the outer side wall of the pool body 1 is fixedly connected with a side wall cleaning motor 20, and the side wall cleaning motor 20 The shaft end passes through the side wall of the pool body 1 and extends into the pool body 1. The shaft end of the side wall cleaning motor 20 is covered with a turntable 21, and the surface of the turntable 21 is fixedly connected with a fixed rod 22 near the edge. The fixed rod 22 Upper cover is provided with connecting rod 23, and connecting rod 23 is rotatably connect...

Embodiment 1、 Embodiment 2

[0027] In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the sewage is injected into the pool body 1 through the water injection pipe 24, and the aeration blade 5 is always floated on the surface of the sewage by using the buoyancy tank 6, and the aeration motor 3 drives The rotating shaft 4 rotates, and then drives the aeration blade 5 to rotate, and uses the aeration blade 5 to raise the surface sewage, so that the surface sewage is fully contacted with the air, aerates the surface sewage, starts the blower 13, and transports the air to the aeration pan 12, The aeration head on the surface of the aeration plate 12 is discharged into the sewage to aerate the bottom sewage. When the rotating shaft 4 rotates, the stirring shaft 7 is driven to rotate, and the bottom sewage is stirred by the stirring shaft 7 and the stirring rod 8, so that the bottom sewage and air bubbles are fully Mixing to improve aeration efficiency. When it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com