Burner fire cover for gas cooking appliance

A gas cooker and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as insufficient combustion and reduced air volume, and achieve the effects of enhanced applicability, reduced flow rate, and good flame stabilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

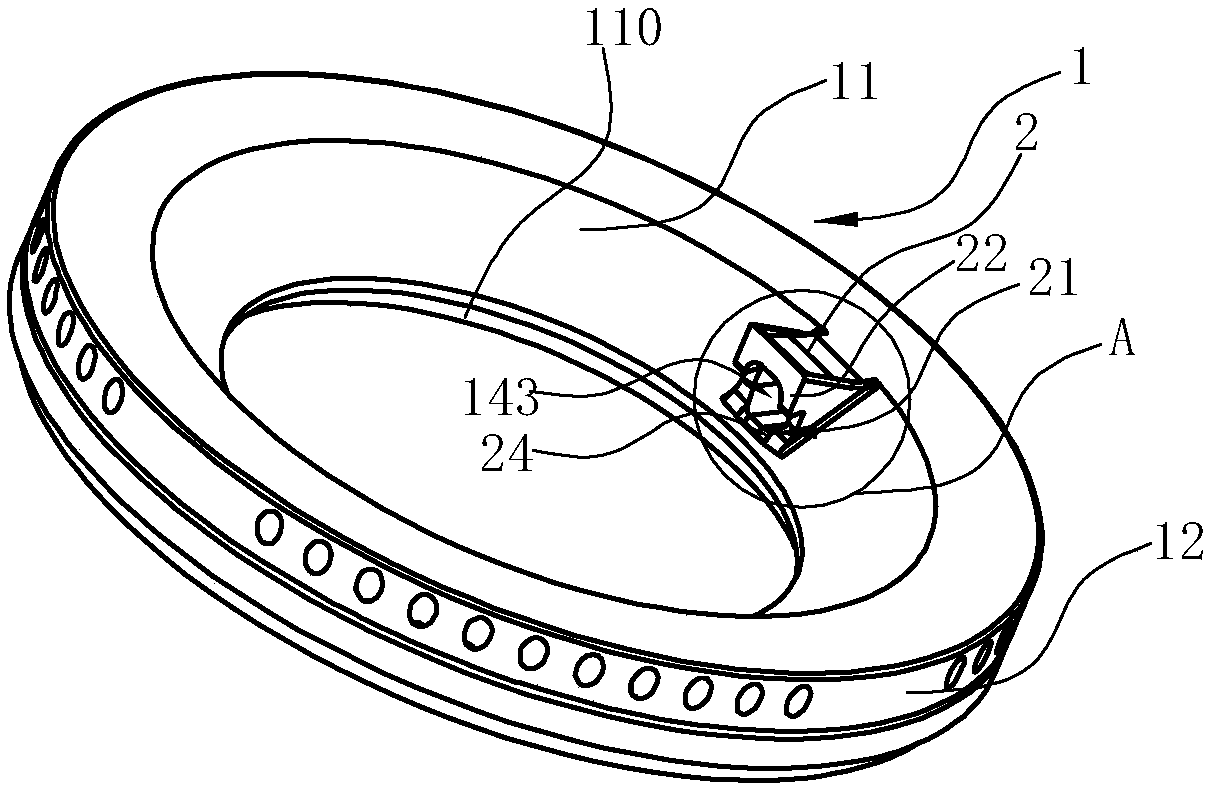

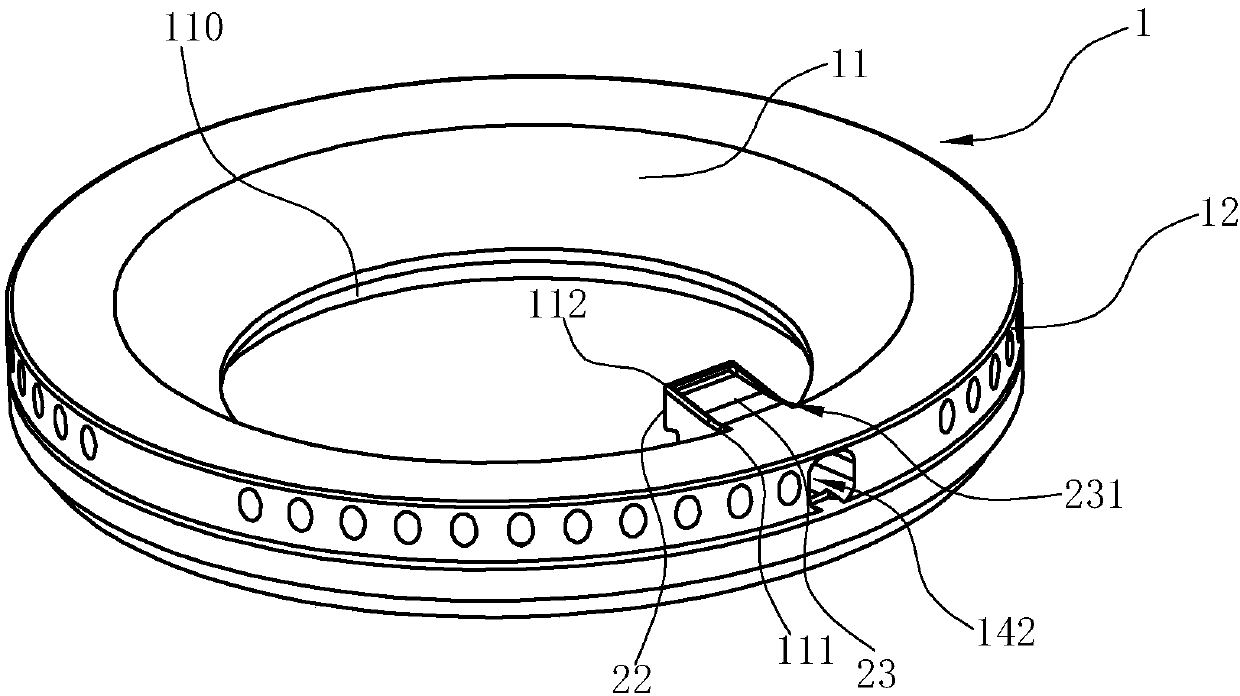

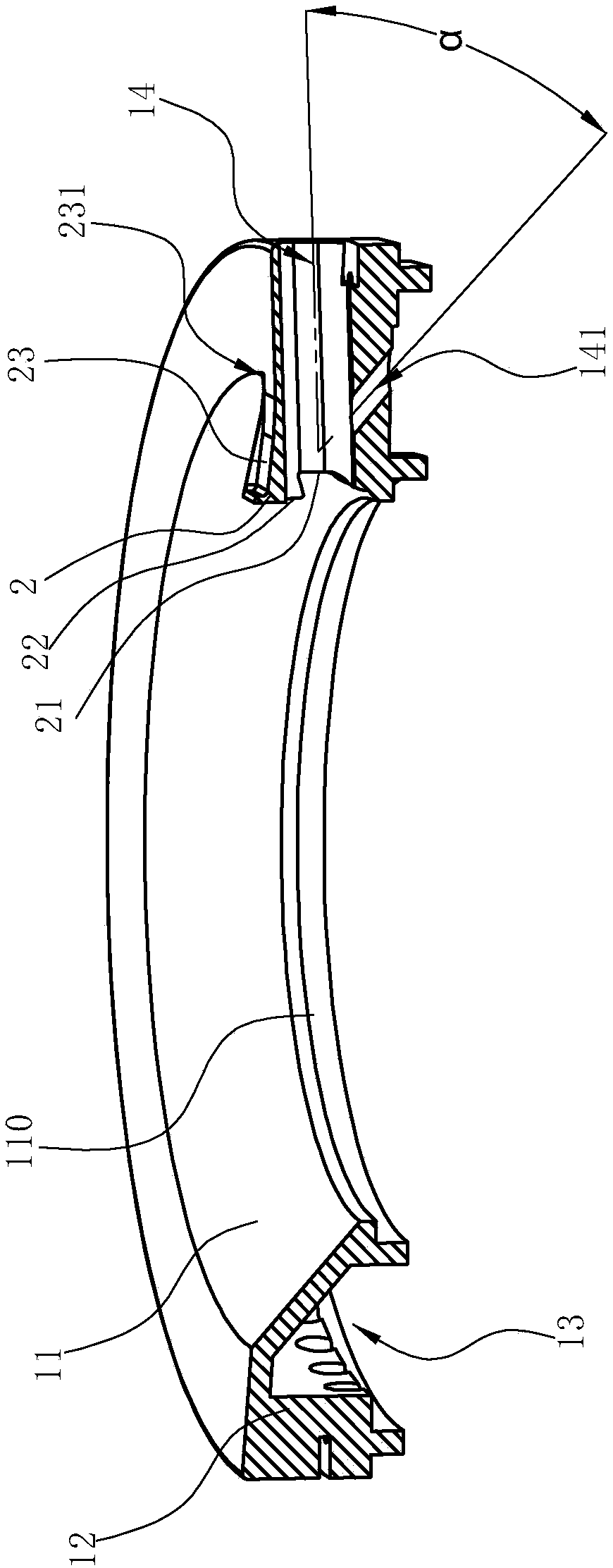

[0025] Such as Figure 1~4 Shown is the preferred embodiment of the present invention. The burner fire cover of the gas cooker in this embodiment includes a fire cover body 1, an annular top wall of the fire cover body 1 and vertical or obliquely extending downwards from the inner edge 110 and the outer edge of the annular top wall. A gas mixing chamber 13 is formed between the inner ring wall 11 and the outer ring wall 12, and a horizontal fire hole 14 is opened in the radial direction inside the fire cover body 1, and a passage connecting the gas mixing chamber 13 is opened at the bottom of the horizontal fire hole 14. The hole 141, the lateral opening 142 of the lateral fire opening 14 is on the outer ring wall 12, the inner opening 143 of the horizontal fire opening 14 is on the inner ring wall 11, and the inner ring wall 11 is facing the fire cover body 1 on the inner wall corresponding to the opening 143 on the inner side of the horizontal fire opening 14 A boss 2 is fo...

Embodiment 2

[0031] The structure is basically the same as that of Embodiment 1, the difference is that there is no notch 21 at the lower part of the opening 143 inside the corresponding horizontal fire hole 14 on the vertical end face of the horizontal fire hole 14, as Figure 5 shown.

Embodiment 3

[0033] The structure is basically the same as that of Example 1, the difference is that a strip-shaped groove 20 corresponding to the horizontal fire-fire hole 14 is provided below the horizontal fire-fire hole 14, and the strip-shaped groove 20 can further reduce the gas outlet speed and improve the flame stabilization ability ,Such as Figure 6 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap