Radar board mounting structure and radar

A technology for mounting structures and radar boards, applied in measuring devices, instruments, radio wave measuring systems, etc., can solve the problems that circuit board mounting boards are not directly suitable for radar board installation, etc., to reduce product scrap rate, reduce processing cost, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention.

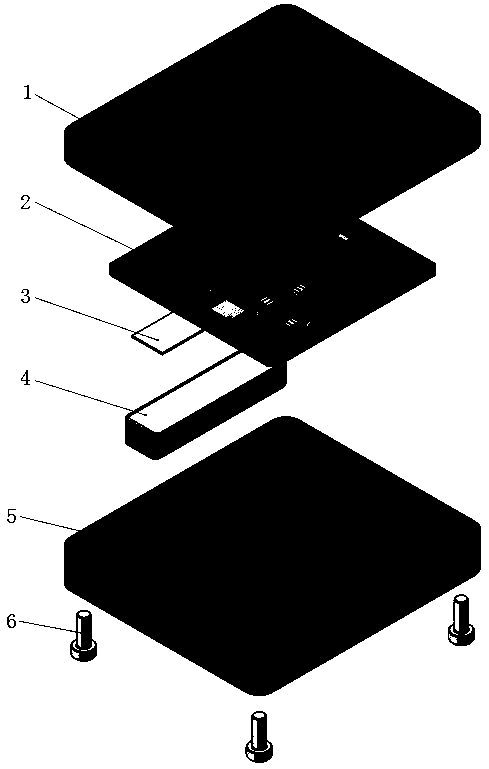

[0030] as attached Figure 1~5 As shown, it is a radar of embodiment 1, including the following structural parts: upper cover (1), radar board (2), heat conduction sheet (3), heat dissipation module (4), base (5), fasteners (6); the upper cover (1) and the base (5) are made of light plastic material, and the heat dissipation module (8) is made of metal material; it includes a radar board installation structure and a radar heat dissipation structure.

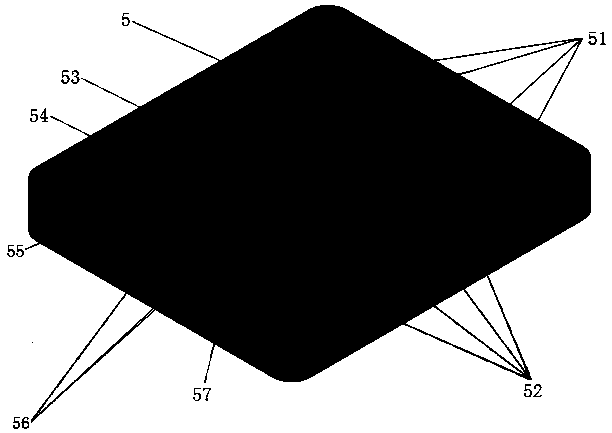

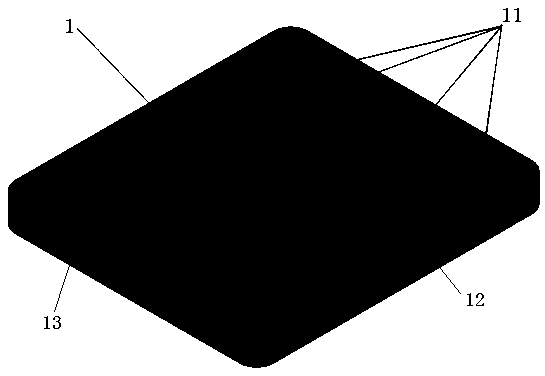

[0031] A radar board mounting structure, as attached Figure 1~3 As shown, the base (5) includes: the radar board support column (51), the limit rib (52), the radar board installation frame (53), the sealing groove (54), the positioning hole (57); the upper cover (1) Including: radar board pressure column (11), sealing groove layer (12), positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com