System and method for realizing low-delay industrial real-time data acquisition

A technology of real-time data collection and industrial data, applied in transmission systems, machine-to-machine/machine-type communication services, electrical components, etc., can solve problems such as high investment costs, data delays, and isolated operation of PLC/DCS processes. Reach the effect of low cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

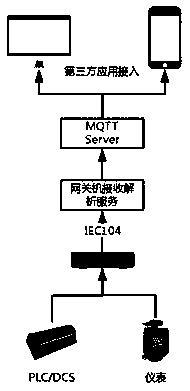

[0017] Such as figure 1 The shown low-latency industrial real-time data acquisition system includes an industrial data acquisition module, and the industrial data acquisition module is connected to a gateway machine in communication; the gateway machine is connected to an MQTT server in communication; and the MQTT server is connected to a third-party system in communication .

[0018] Wherein, the industrial data acquisition module is at least one of production field instrument, PLC and DCS.

[0019] Among them, the model of the gateway machine is NARI 9110, the development tool is visual studio 2017, the development framework is .NETCore 2.0, and the development language is C#.

Embodiment 2

[0021] Such as figure 1 As shown, a method for realizing low-latency industrial real-time data acquisition, the method is as follows: the real-time data collected is forwarded by the industrial data acquisition gateway carried by the scada system, and the multi-channel forwarding of the gateway machine is set; Data protocol, develop independent receiving analysis service, bypass scada's overall data processing process to reduce time delay; after data analysis is completed, it will be connected with the IoT message platform and provided to a third party or upper management system for consumption; when setting, the details are as follows : 1. Set the multi-channel forwarding mode of the gateway machine; 2. Develop the receiving and analyzing service of the gateway machine: use Socket technology to establish a communication connection with the gateway machine, and call and analyze the data according to the requirements of the IEC104 protocol; 3. Send the processed data to the MQTT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com