Manufacturing device and grinding method for fine line multi-layer circuit board

A multi-layer circuit board, fine circuit technology, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of grinding accuracy, defects, reduce the end face grinding efficiency, etc., to reduce labor intensity and improve grinding Efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

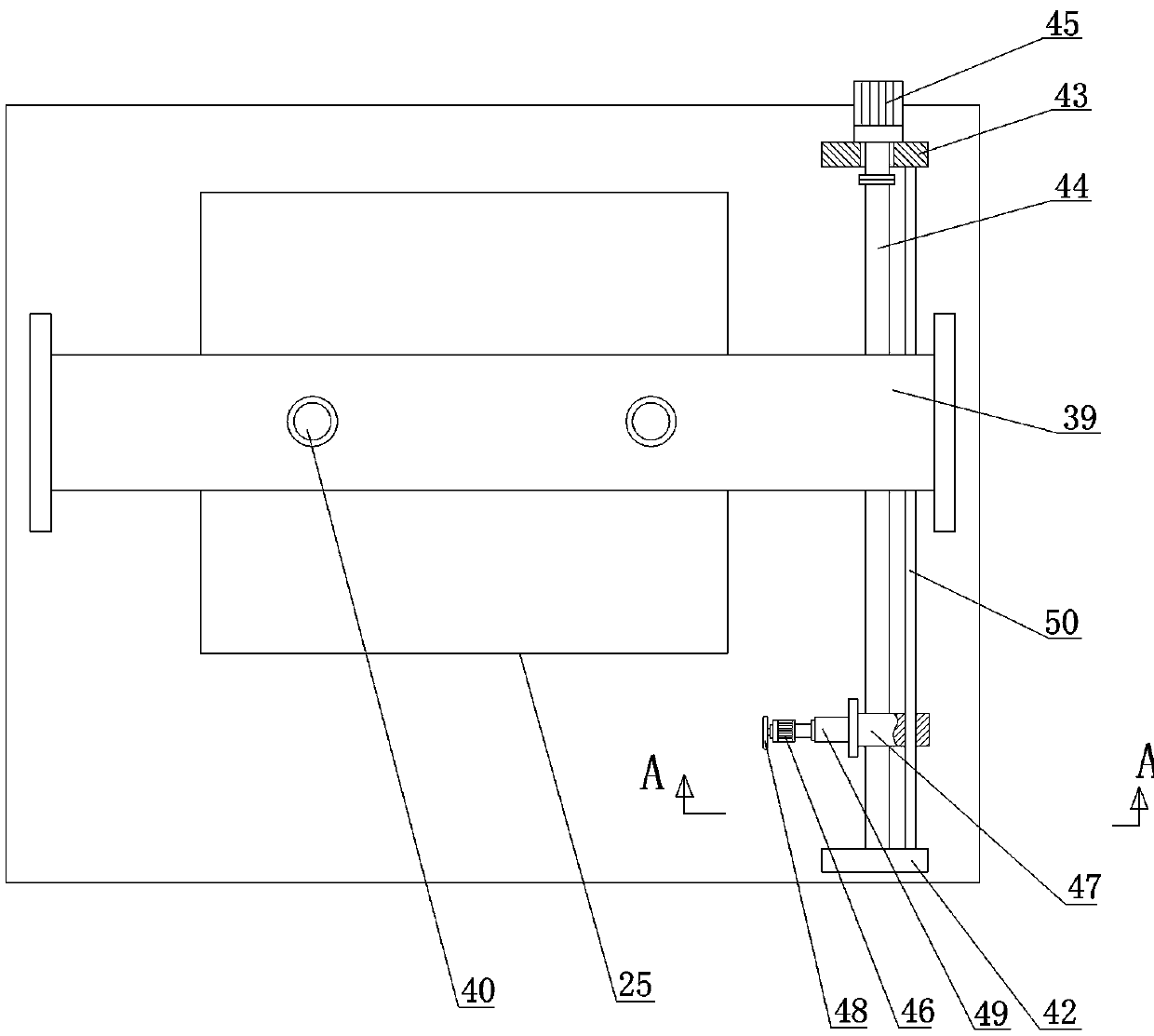

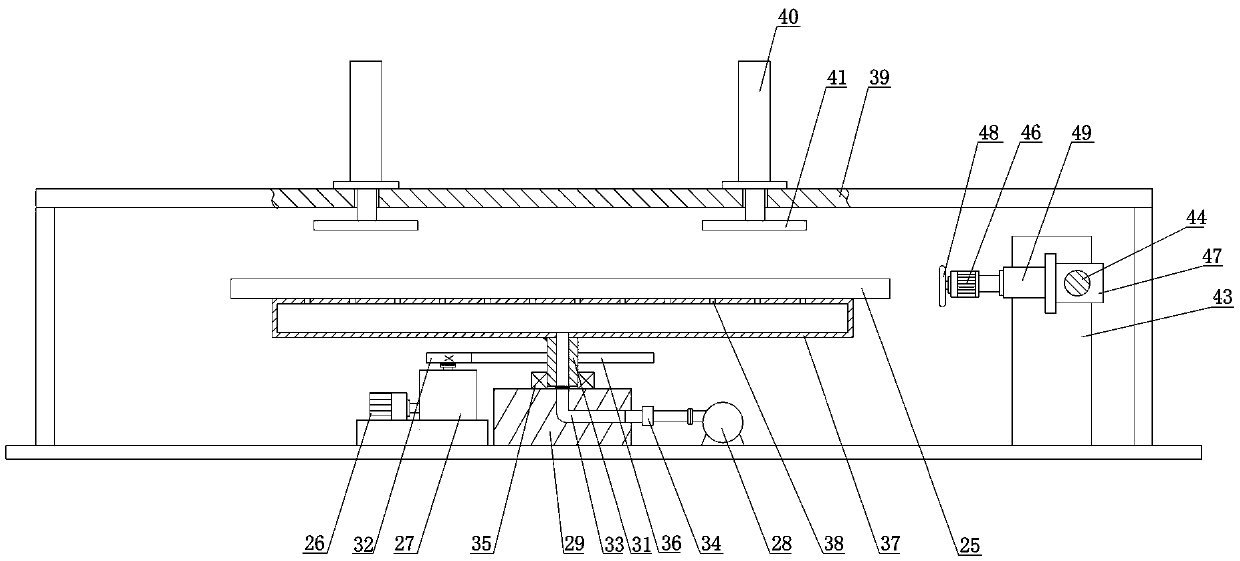

[0018] like Figure 1~2 Shown, the manufacturing device of fine line multilayer circuit board, it comprises pressing device, rotating device and polishing device, and described rotating device comprises motor A26, reduction box 27, vacuum pump 28, carrying platform 29 and hollow shaft 31, described The output shaft of the motor A26 is connected with the input shaft of the reduction box 27 through a coupling, and the output shaft of the reduction box 27 is equipped with a driving gear 32, and an L-shaped channel 33 is provided in the bearing table 29, and one end of the L-shaped channel 33 Through the top of the bearing platform 29, the other end of the L-shaped channel 33 runs through the side wall of the bearing platform 29, and the port is provided with a joint 34, the top of the bearing platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com