A high-performance oxygen evolution cobalt diselenide/nickel tetraselenide@nc/c composite catalyst and its preparation method and application

A composite catalyst, high-performance technology, applied in the field of electrocatalysis, can solve the problem of non-conductivity, etc., and achieve the effect of improving poor conductivity, promoting comprehensive performance, and promoting improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

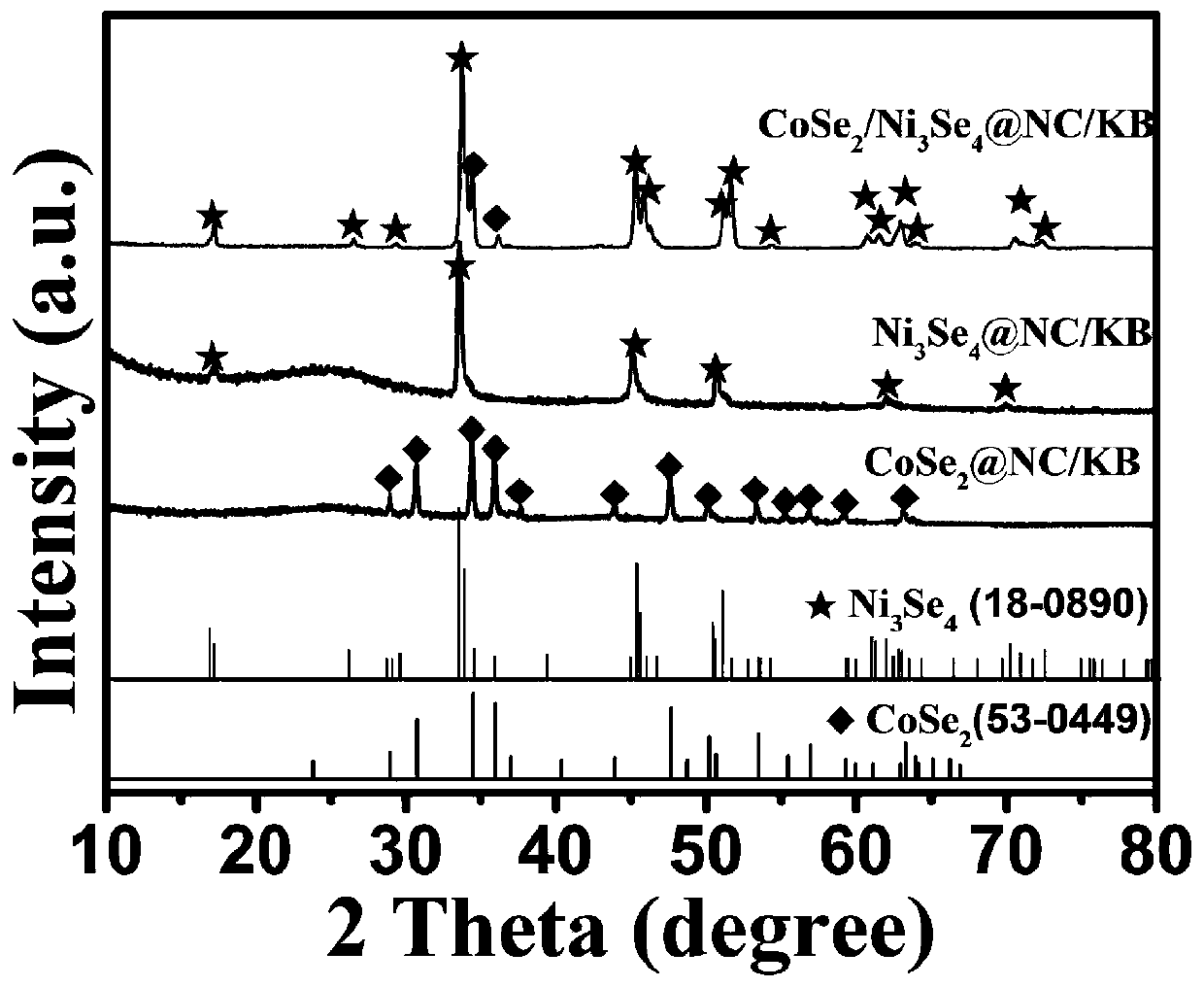

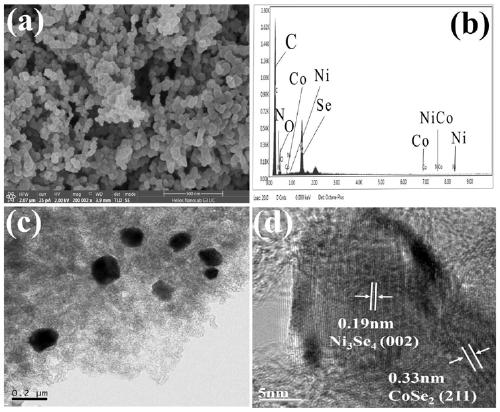

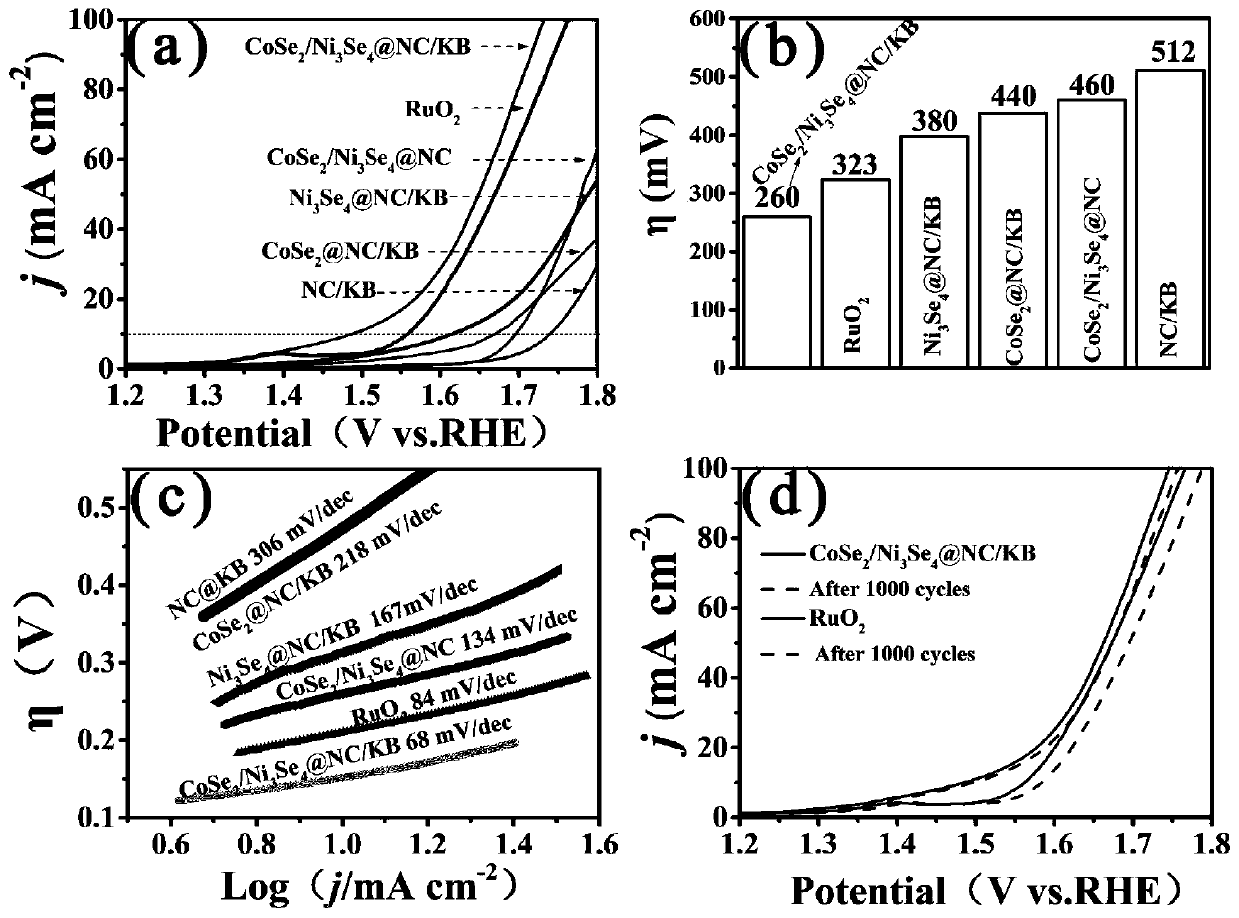

[0044] CoSe 2 / Ni 3 Se 4 Preparation of @NC / KB

[0045]Dissolve 1 mmol of cobalt nitrate hexahydrate, 1 mmol of nickel nitrate hexahydrate and 2 g of dicyandiamide in 20 mL of deionized water, ultrasonicate for 15 min, then stir the resulting mixture at 80°C and evaporate to dryness, and finally place the resulting solid mixture in a nitrogen atmosphere Under protection, the temperature was raised to 550°C at a rate of 5°C / min and kept for 2 hours. After the solid powder is cooled under the protection of nitrogen, it is taken out to obtain Ni / Co / CoO / NiCo 2 o 4 -g -C 3 N 4 .

[0046] Weigh 0.2g Ni / Co / CoO / NiCo 2 o 4 -g -C 3 N 4 Solid powder, 1g of selenium dioxide and 0.1g of Ketjen carbon were dispersed in 50mL of dimethylformamide aqueous solution (the volume of dimethylformamide and water was 5:2), stirred at room temperature for 1h and then transferred to an autoclave And keep it warm in a 200°C electric blast drying oven for 20h. After cooling at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com