Steel material monitoring adjusting system for steel forging and working method thereof

A technology for adjusting system and steel, applied in the field of steel forging, can solve problems such as excessive heat loss, increase forging time, reduce work efficiency, etc., and achieve the effects of improving management level, reducing scrap rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] refer to Figure 1-2 as an example.

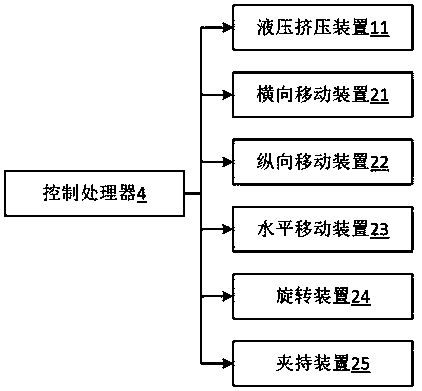

[0055] A steel monitoring and adjusting system for iron and steel forging, including: a forging device, a fixing device, and also includes: a control processor 4 and a monitoring device.

[0056] The forging device includes: a hydraulic extrusion device 11, a molding device, and a force transmission device.

[0057] The hydraulic extruding device 11 includes a first extruding device and a second extruding device, and the first extruding device and the second extruding device are arranged oppositely on the upper and lower sides respectively. The hydraulic extruding device 11 is used to apply extruding force to the middle, and is used for waking up the steel. The steel material is disposed between the first hydraulic extrusion device 11 and the second hydraulic extrusion device 11 .

[0058] There are two identical force transmission devices, which are respectively connected with the first extruding device and the second extruding ...

Embodiment 2

[0071] refer to image 3 as an example.

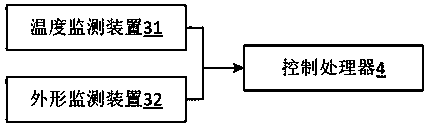

[0072] This embodiment is basically the same as the first embodiment above, except that, as a preferred mode of the present invention, the temperature monitoring device 31 presets at least three temperature monitoring positions, and the temperature monitoring device 31 monitors the temperatures of the three temperature monitoring positions , and output the real-time temperature value of the preset temperature monitoring position to the control processor 4 .

[0073] As a preferred mode of the present invention, the profile monitoring device 32 presets at least three monitoring surfaces, the profile monitoring device 32 monitors the profile data of the three monitoring surfaces, and outputs the profile data of the preset monitoring surfaces to the control processor 4 .

[0074] The positions of the three detection surfaces can be different surfaces of the steel.

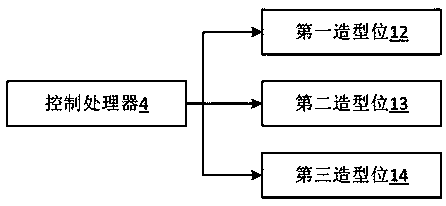

[0075] As a preferred mode of the present invention, the molding devic...

Embodiment 3

[0078] This embodiment is basically the same as the above embodiment, the difference is that, as a preferred mode of the present invention, the following steps are included:

[0079] S101: The control processor 4 outputs a clamping signal to the clamping device 25, and the clamping device 25 clamps the steel material.

[0080] S102: The control processor 4 outputs moving signals to the vertical moving device 22, the horizontal moving device 21, and the horizontal moving device 23 respectively, so as to move the clamped steel material between the molding devices.

[0081] S103: The control processor 4 outputs a pressure signal to the first extrusion device and the second extrusion device, and the first extrusion device and the second extrusion device are turned on.

[0082] S104: The temperature monitoring device 31 monitors the temperature of the steel, and converts the temperature into a real-time temperature value and outputs it to the control processor 4 .

[0083] S104: T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com