Accurate drug adding calibration system

A calibration system and accurate technology, applied in chlorine dioxide, chlorine oxide and other directions, can solve the problems of water quality safety hazards, production impact, inconsistent dosage of drugs, etc., achieving high accuracy, simple operation methods, and reducing cumbersome and complex problems. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

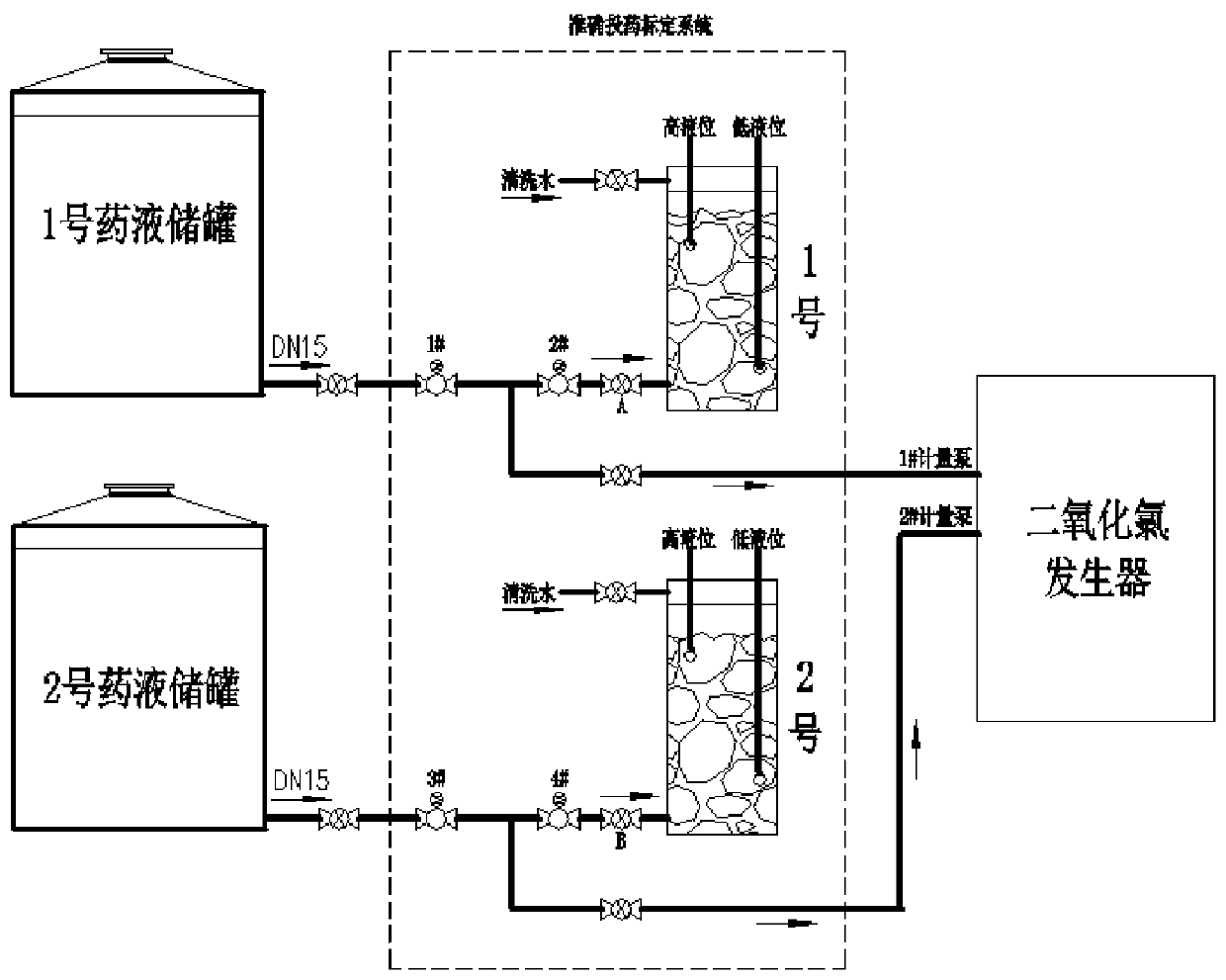

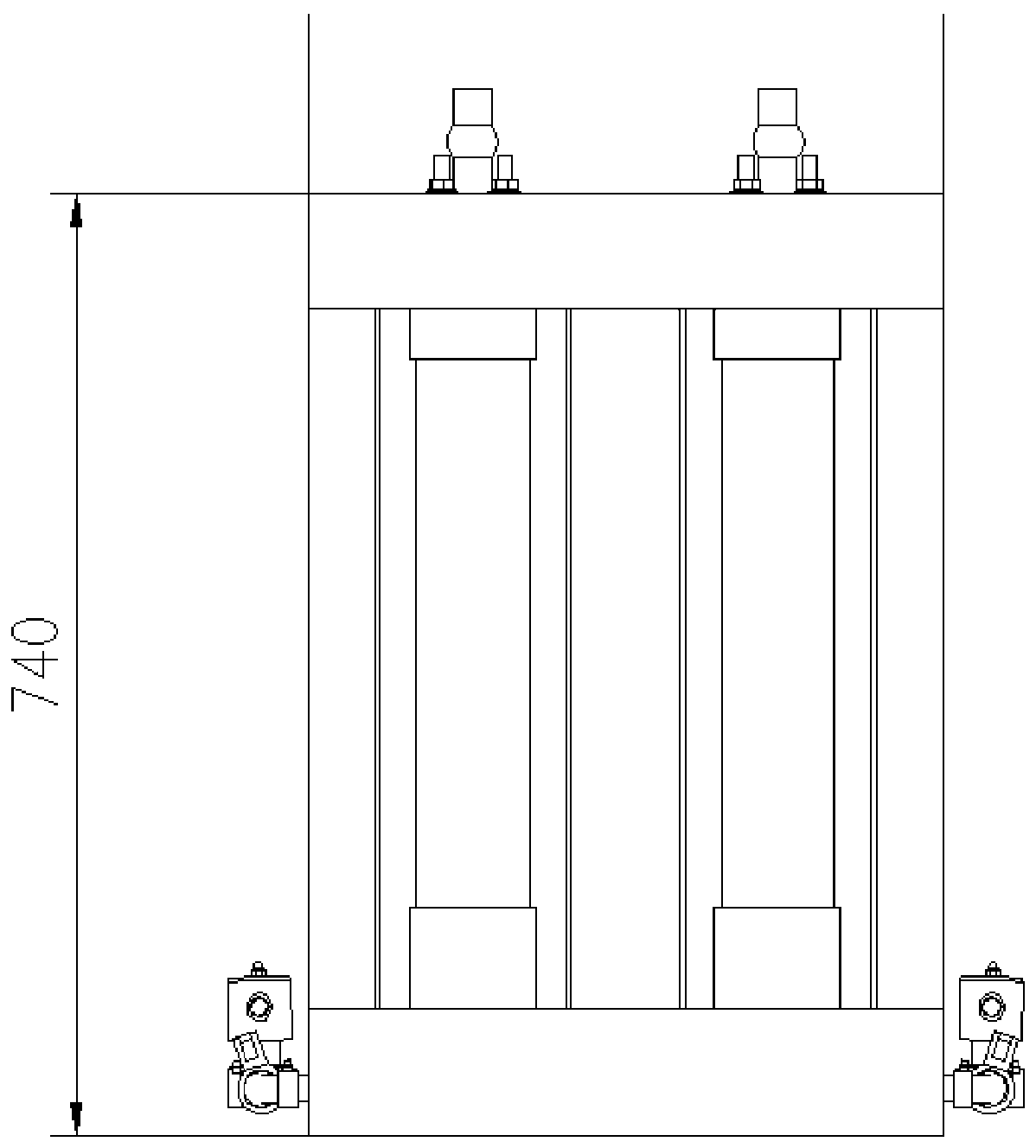

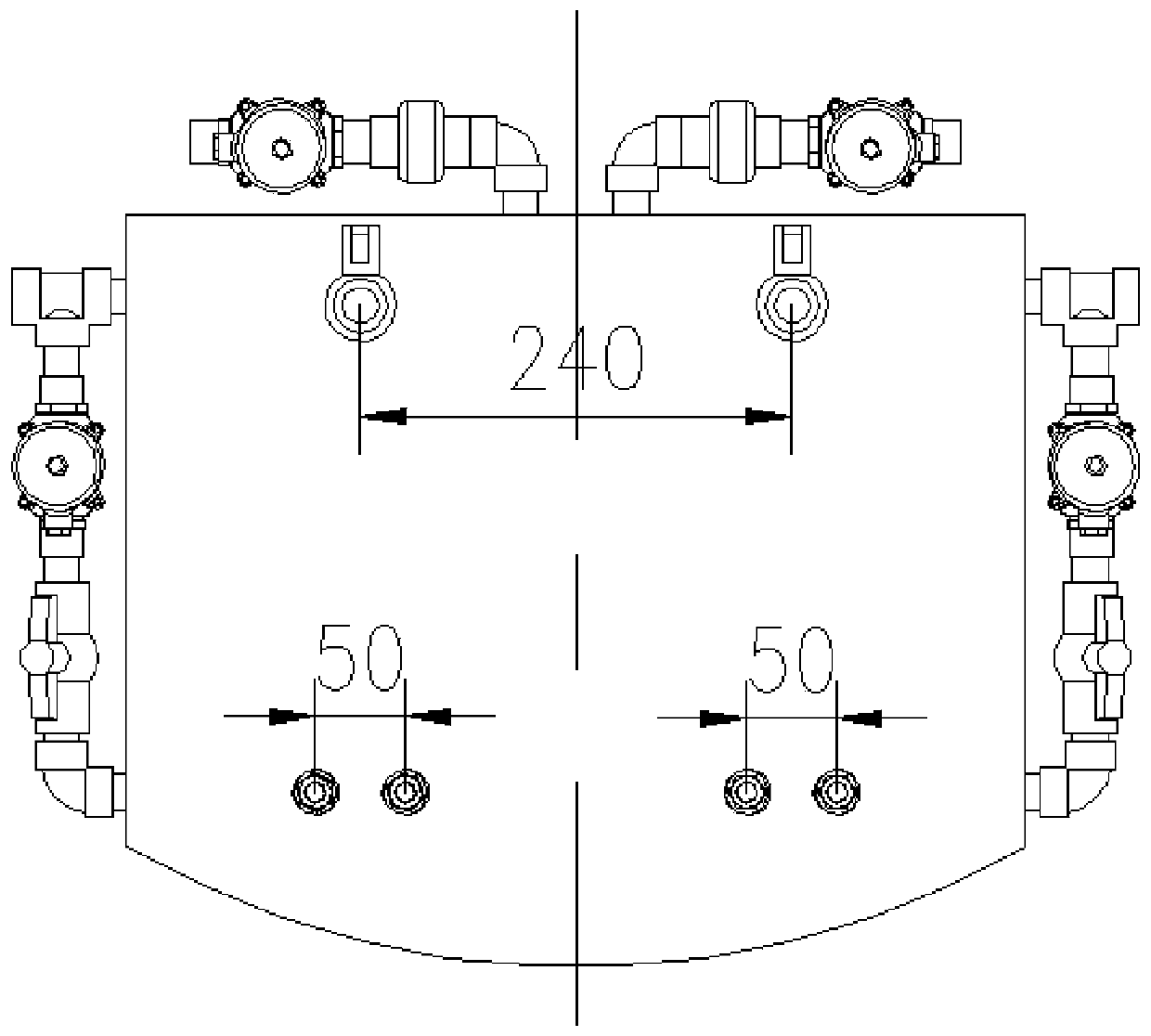

[0035] An accurate dosing calibration system, comprising: No. 1 medicinal liquid storage tank, No. 2 medicinal liquid storage tank, No. 1 calibration tank, No. 2 calibration tank, chlorine dioxide generator, the No. 1 medicinal liquid storage tank and the No. 1 calibration tank is arranged between the chlorine generators, No. 2 calibration tank is arranged between the No. 2 medicinal liquid storage tank and the chlorine dioxide generator, and the No. 1 medicinal liquid storage tank, chlorine dioxide generator, There is a 1# solenoid valve between the intersection point I of the No. 1 calibration tank pipeline and the No. 1 liquid storage tank, and a 2# solenoid valve is set between the intersection point I and the No. 1 calibration tank. The No. 2 liquid storage tank , Chlorine dioxide generator, No. 2 calibration tank pipeline intersection point Ⅱ and No. 2 chemical liquid storage tank are provided with a 3# solenoid valve, and a 4# solenoid valve is provided between the inter...

Embodiment 2

[0048] An accurate dosing calibration system, comprising: No. 1 medicinal liquid storage tank, No. 2 medicinal liquid storage tank, No. 1 calibration tank, No. 2 calibration tank, chlorine dioxide generator, the No. 1 medicinal liquid storage tank and the No. 1 calibration tank is arranged between the chlorine generators, No. 2 calibration tank is arranged between the No. 2 medicinal liquid storage tank and the chlorine dioxide generator, and the No. 1 medicinal liquid storage tank, chlorine dioxide generator, There is a 1# solenoid valve between the intersection point I of the No. 1 calibration tank pipeline and the No. 1 liquid storage tank, and a 2# solenoid valve is set between the intersection point I and the No. 1 calibration tank. The No. 2 liquid storage tank , Chlorine dioxide generator, No. 2 calibration tank pipeline intersection point Ⅱ and No. 2 chemical liquid storage tank are provided with a 3# solenoid valve, and a 4# solenoid valve is provided between the inter...

Embodiment 3

[0052] An accurate dosing calibration system, comprising: No. 1 medicinal liquid storage tank, No. 2 medicinal liquid storage tank, No. 1 calibration tank, No. 2 calibration tank, chlorine dioxide generator, the No. 1 medicinal liquid storage tank and the No. 1 calibration tank is arranged between the chlorine generators, No. 2 calibration tank is arranged between the No. 2 medicinal liquid storage tank and the chlorine dioxide generator, and the No. 1 medicinal liquid storage tank, chlorine dioxide generator, There is a 1# solenoid valve between the intersection point I of the No. 1 calibration tank pipeline and the No. 1 liquid storage tank, and a 2# solenoid valve is set between the intersection point I and the No. 1 calibration tank. The No. 2 liquid storage tank , Chlorine dioxide generator, No. 2 calibration tank pipeline intersection point Ⅱ and No. 2 chemical liquid storage tank are provided with a 3# solenoid valve, and a 4# solenoid valve is provided between the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com