Method for advanced treatment of organic matter in high-salt wastewater under synergism of electrochemistry and persulfate

A high-salt wastewater, persulfate technology, applied in water pollutants, water/sewage treatment, water treatment parameter control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

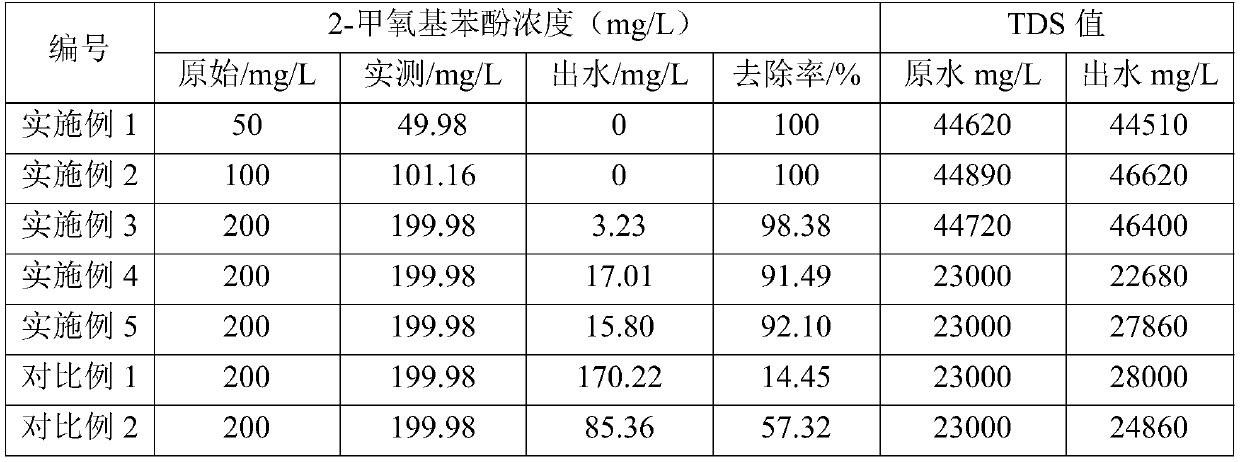

[0034] The method for the advanced treatment of organic matter in high-salt wastewater by electric cooperation with persulfate described in this embodiment comprises the following steps

[0035] (1) get 2-methoxyphenol concentration and be 300mL waste water (TDS value sees table 1 below) of 50mg / L in the reactor, add 0.3g sodium persulfate, make the sodium persulfate concentration in the solution be 1g / L ( Now the solution is neutral, the pH is about 7), and the initial pH of the waste water is adjusted to be 12 with NaOH;

[0036] (2) Insert a pair of carbon plate electrodes (5×2.5cm) into the reactor, keep the distance between the plates at 3cm, supply power from a constant voltage power supply, set the voltage at 2V, start the sulfate radical oxidation reaction, and the reaction time is 3h .

[0037] After the reaction is over, turn off the power and take out the electrode to terminate the reaction, and the solution in the reactor is the reaction effluent.

Embodiment 2

[0039] The method for the advanced treatment of organic matter in high-salt wastewater by electric cooperation with persulfate described in this embodiment comprises the following steps

[0040] (1) get 2-methoxyphenol concentration and be 300mL waste water (TDS value sees table 1 below) of 100mg / L in reactor, add 0.9g sodium persulfate, make sodium persulfate concentration be 3g / L in the solution, And adjust the initial pH of the wastewater to be 12;

[0041] (2) Insert a pair of carbon plate electrodes (5×2.5cm) into the reactor, keep the distance between the plates at 3cm, supply power from a constant voltage power supply, set the voltage at 2V, start the sulfate radical oxidation reaction, and the reaction time is 3h .

[0042] After the reaction is over, turn off the power and take out the electrode to terminate the reaction, and the solution in the reactor is the reaction effluent.

Embodiment 3

[0044] The method for the advanced treatment of organic matter in high-salt wastewater by electric cooperation with persulfate described in this embodiment comprises the following steps

[0045] (1) get 2-methoxyphenol concentration and be 300mL waste water (TDS value sees table 1 below) of 200mg / L in reactor, add 1.5g sodium persulfate, make sodium persulfate concentration be 5g / L in the solution, And adjust the initial pH of the wastewater to be 12;

[0046] (2) Insert a pair of carbon plate electrodes (5×2.5cm) into the reactor, keep the distance between the plates at 3cm, supply power from a constant voltage power supply, set the voltage at 2V, start the sulfate radical oxidation reaction, and the reaction time is 3h .

[0047] After the reaction is over, turn off the power and take out the electrode to terminate the reaction, and the solution in the reactor is the reaction effluent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com