Multi-high-rise logistics warehouse modular layout system and application of multi-high-rise logistics warehouse modular layout system to general drawing arrangement

A multi-high-rise, modular technology, applied in building structures, industrial buildings, buildings, etc., can solve the problems of poor land saving, low land utilization, low floor area ratio, etc., to improve the safety factor of vehicles and improve land Utilization rate, the effect of saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The land size of the multi-high-rise logistics warehouse modular layout system provided in this embodiment is about 250m*400m, which can be adapted to a site with a land area of about 100,000 square meters (150 mu).

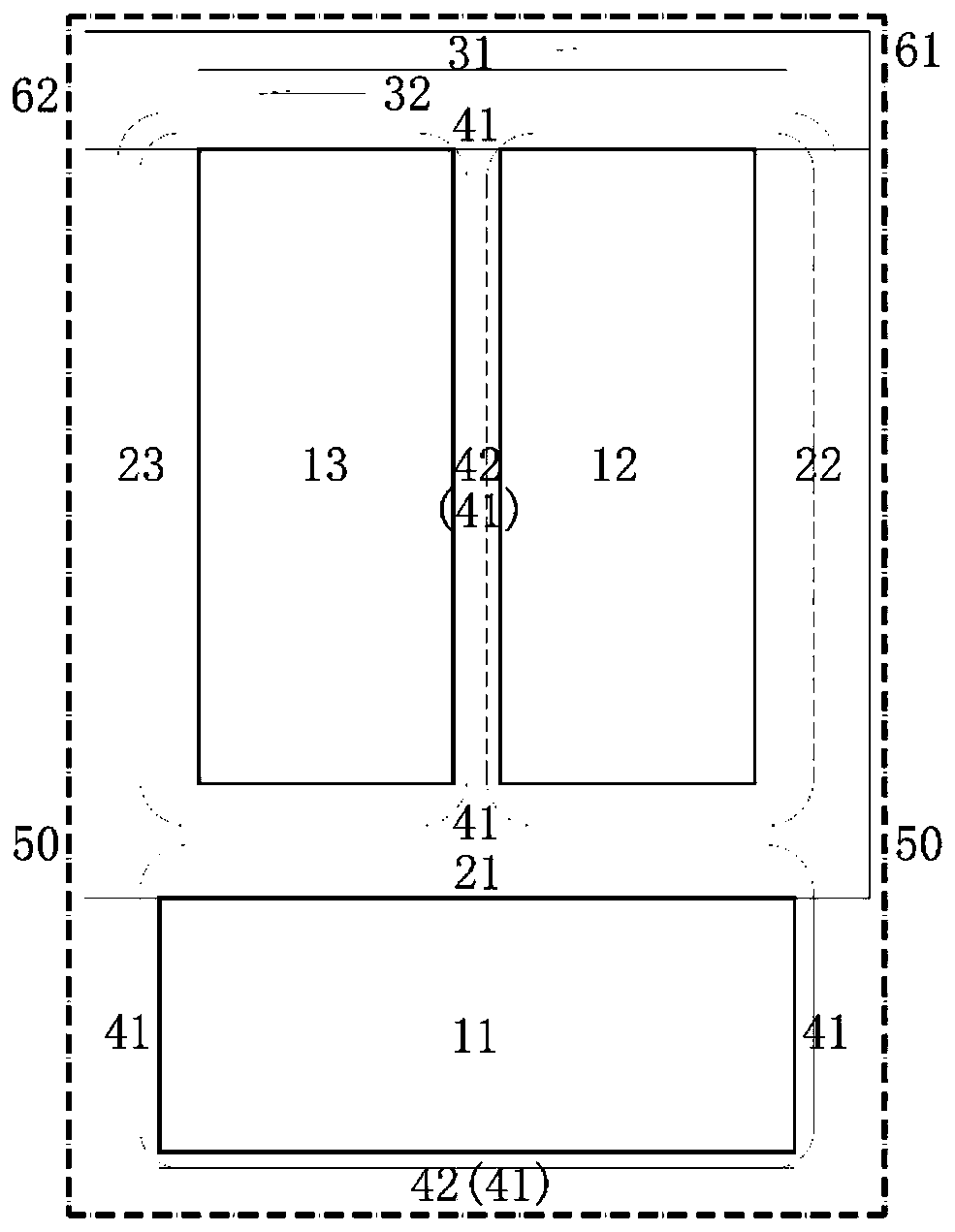

[0042] Figure 1 ~ Figure 3 The schematic diagram of the multi-high-rise logistics warehouse modular layout system provided in this embodiment, the multi-high-rise logistics warehouse modular layout system consists of the first high-rise logistics warehouse 11, the second high-rise logistics warehouse 12, the third high-rise logistics warehouse 13, the third high-rise logistics warehouse One outdoor loading and unloading site (platform) and channel 21, the second outdoor loading and unloading site (platform) and channel 22, the third outdoor loading and unloading site (platform) and channel 23, entrance ramp 31, exit ramp 32, fire lane 41. Composed of fire truck climbing operation site 42 and so on.

[0043] In this embodiment, the first high-rise logis...

Embodiment 2

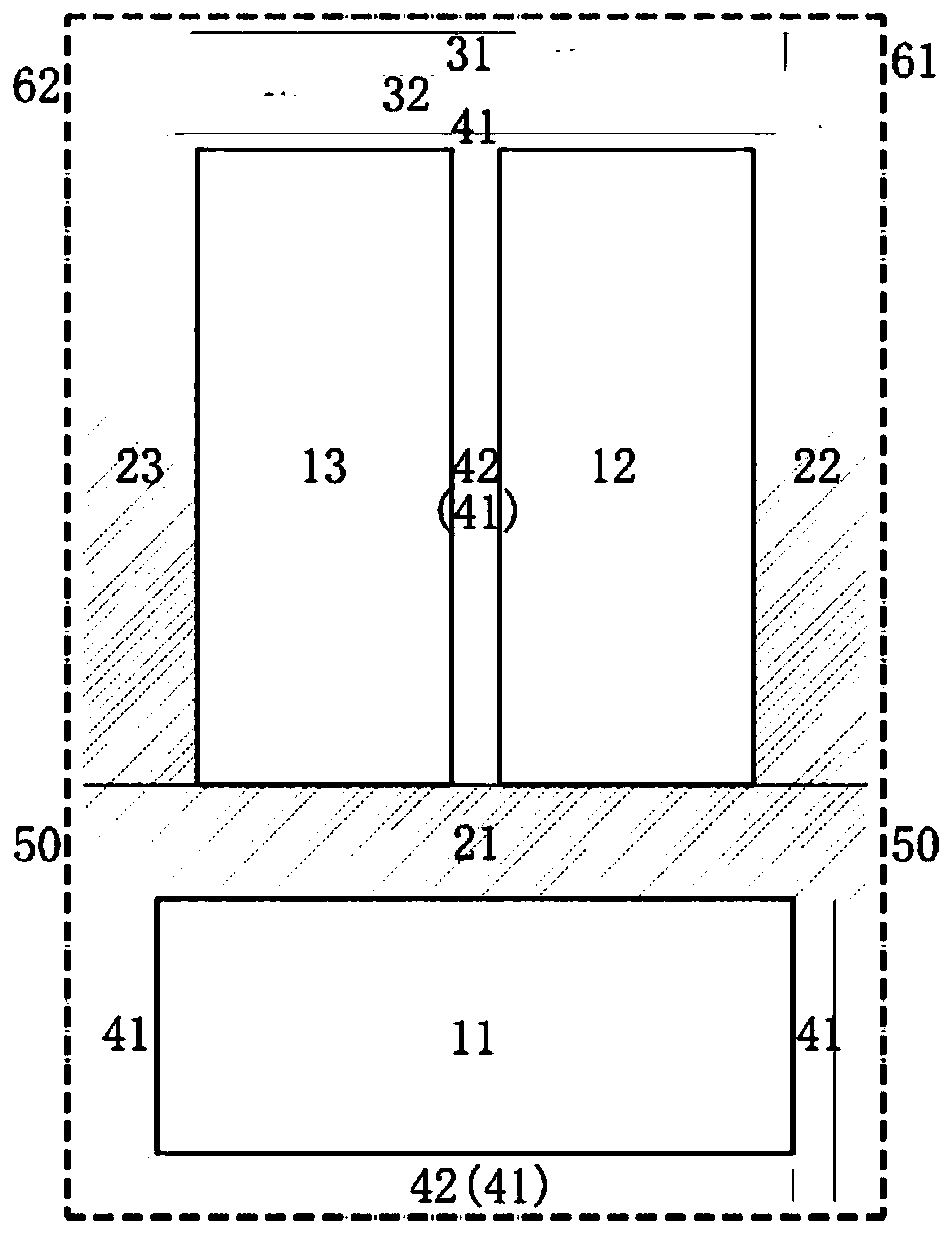

[0056] The land size of the multi-storey logistics warehouse modular layout system provided in this embodiment is the same as that in Embodiment 1, which is also about 250m*400m. The multi-storey logistics warehouse modular layout system includes: three multi-storey logistics warehouses 11, 12, 13; outdoor loading and unloading sites (platforms) and passages 21, 22, 23; entrance ramps 31, exit ramps 32; Firefighting lane 41, fire truck climbing operation site 42.

[0057] In this embodiment, the three multi-storey logistics warehouses 11, 12, and 13 are all three-storey buildings with a building size of 80m in width and 240m in length, and an area of 19200m 2 , the building storey height is 7.5m, and the building height is H<24m. All of them adopt the form of one-side loading and unloading, and each floor is equipped with an outdoor loading and unloading site (platform) and passages 21, 22, and 23.

[0058] This embodiment 2 only slightly adjusts the architectural attribute...

Embodiment 3

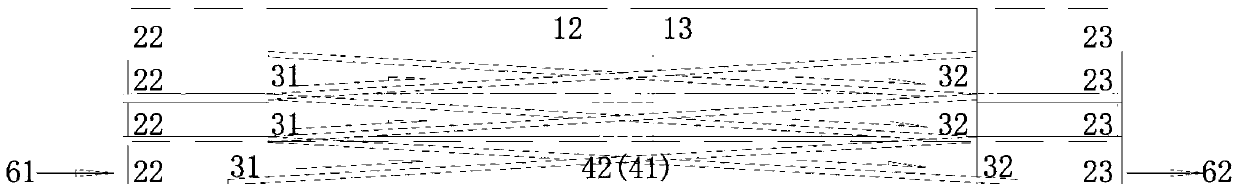

[0063] Such as Figure 6 As shown, this embodiment is a side-by-side combination unit of two standard modules: the recommended aspect ratio of the combination unit is about 5:4, which can be adapted to a site with a land area of about 200,000 square meters (300 mu). In this embodiment, through the side-by-side combination of two standard modules, the land on the south side is two first high-rise logistics warehouses 11 arranged in a "one" shape; the middle land is two sets of second high-rise logistics warehouses 12 in vertical direction, The third high-rise logistics warehouse 13 is arranged in parallel; the land on the north side is two entrance ramps 31, and two exit ramps 32 are arranged in a continuous manner; the outdoor loading and unloading platforms and passages are combined to form a "W"-shaped layout . The combined unit can be optimized as follows:

[0064] Optimization 1: After combination, the intermediate loading and unloading site (platform) and channel 24 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com