High pressure water jet and hob multi-degree-of-freedom combinedrock breaking experiment device

A technology of high-pressure water jets and experimental devices, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problem of less development of composite rock-breaking test benches, and achieve the effect of improving safety, operation convenience, and reasonable and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present invention, the invention will be described more comprehensively and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the scope of protection of the present invention is not limited to the following specific embodiments.

[0032] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. The terminology used herein is only for the purpose of describing specific embodiments, and is not intended to limit the protection scope of the present invention.

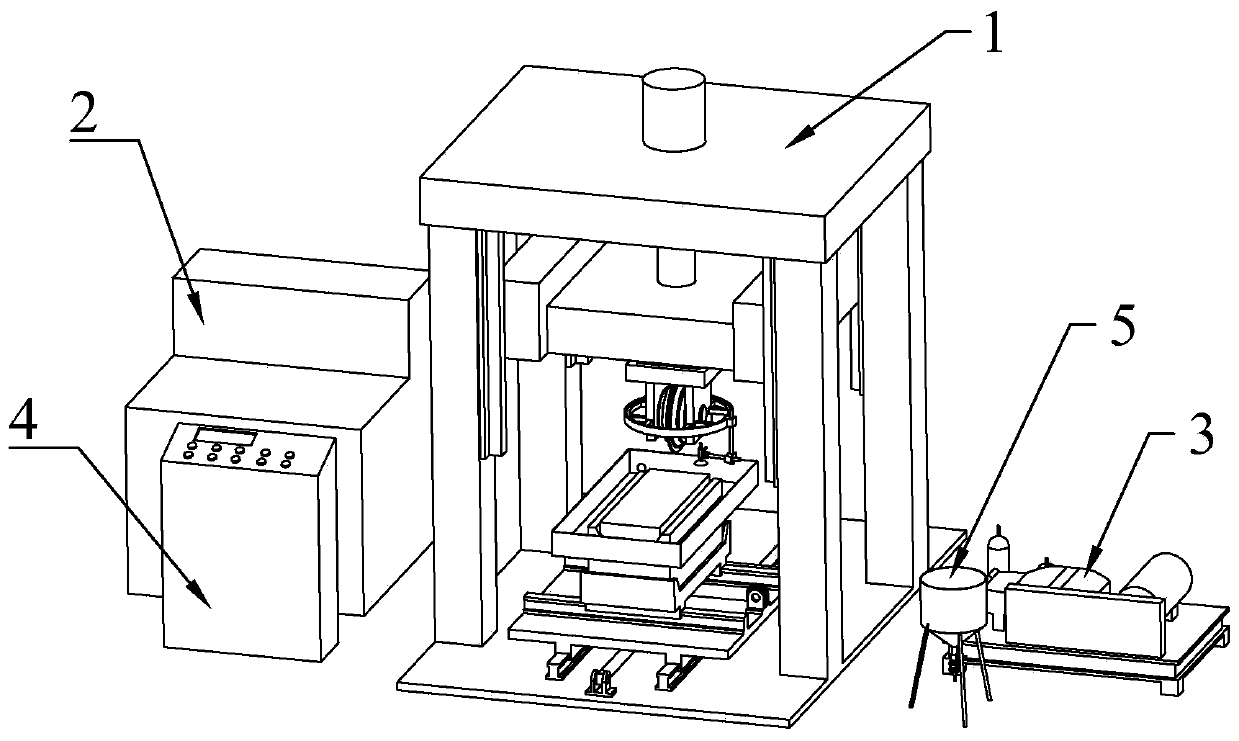

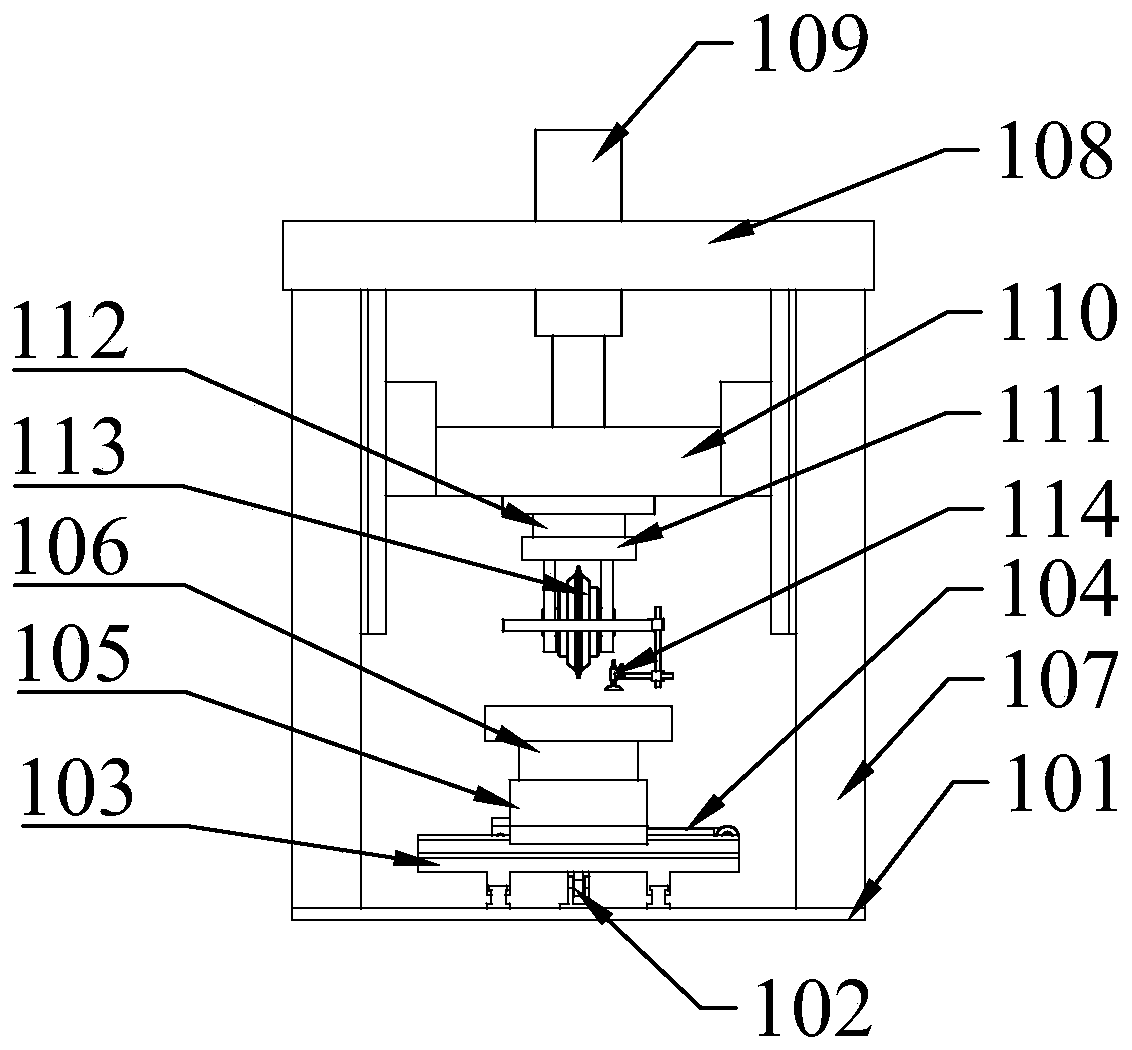

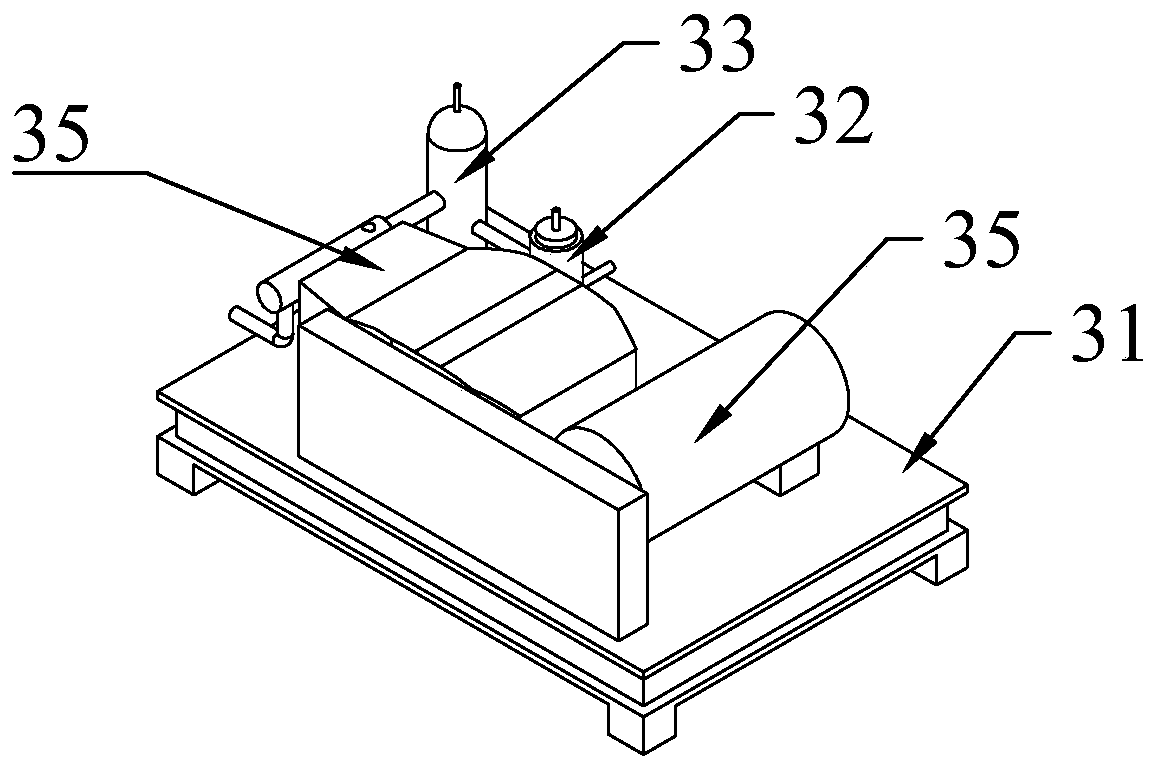

[0033] Such as figure 1 As shown, a high-pressure water jet hob multi-degree-of-freedom composite rock-breaking experimental device is characterized in that it includes a rock-breaking main structure 1, a hydraulic drive system 2 arranged on both sides of the rock-breaking main structure 1, and a water jet pressurization device. 3. Electric control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com