Finite element shape finding analysis method for cable structure

A technology of form-finding analysis and cable structure, which is applied in the fields of instrumentation, calculation, and electrical digital data processing, etc., can solve problems such as numerical convergence, long calculation time, and large amount of calculation, so as to improve speed and accuracy, fast calculation speed, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

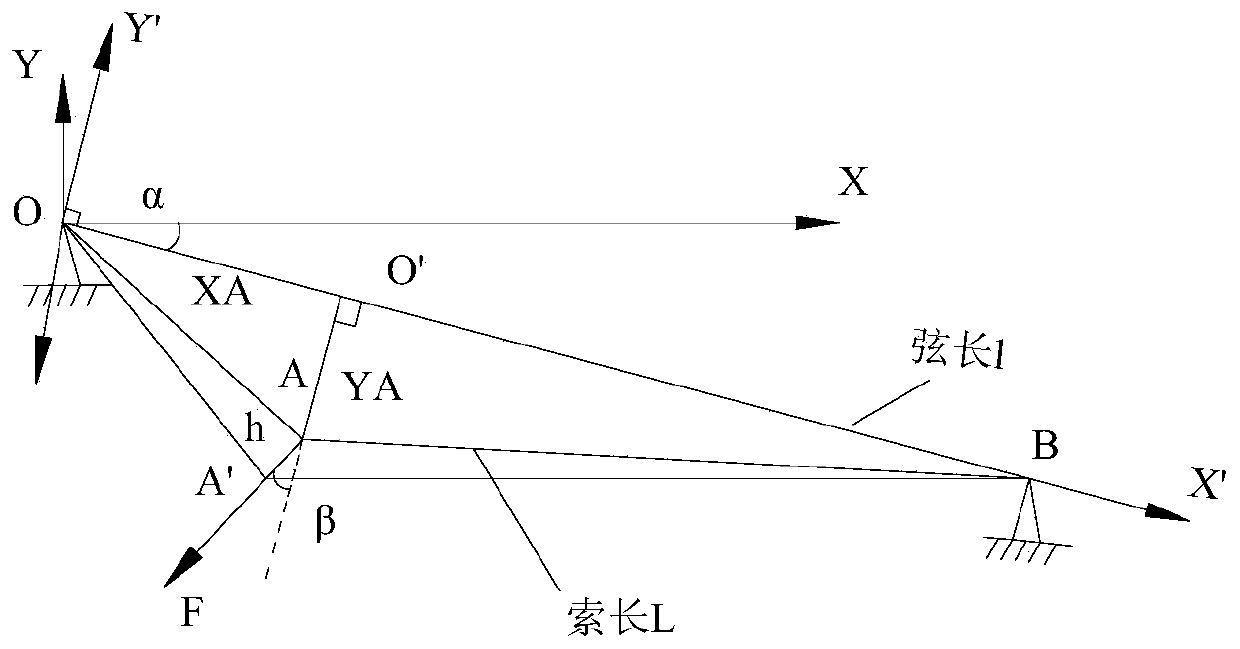

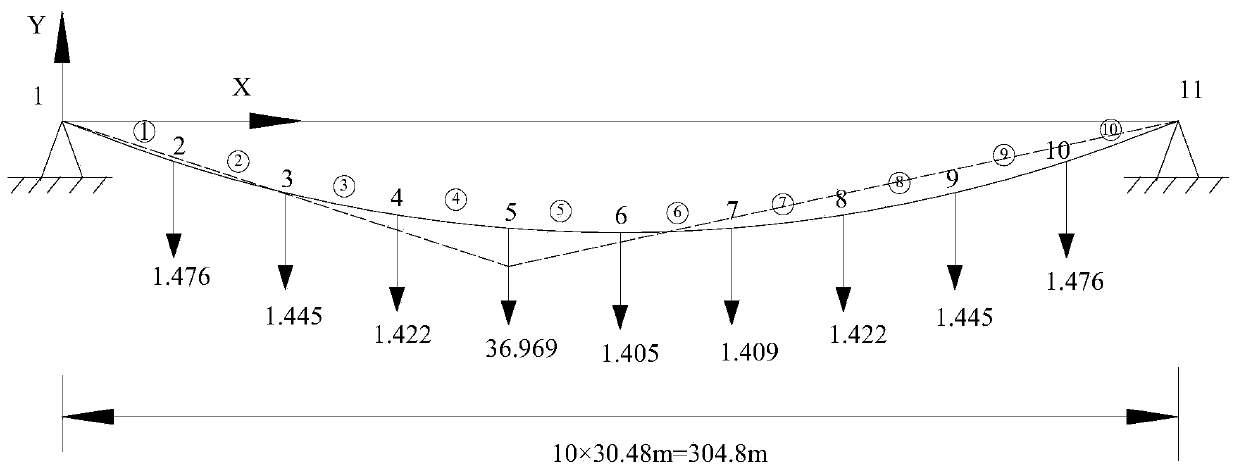

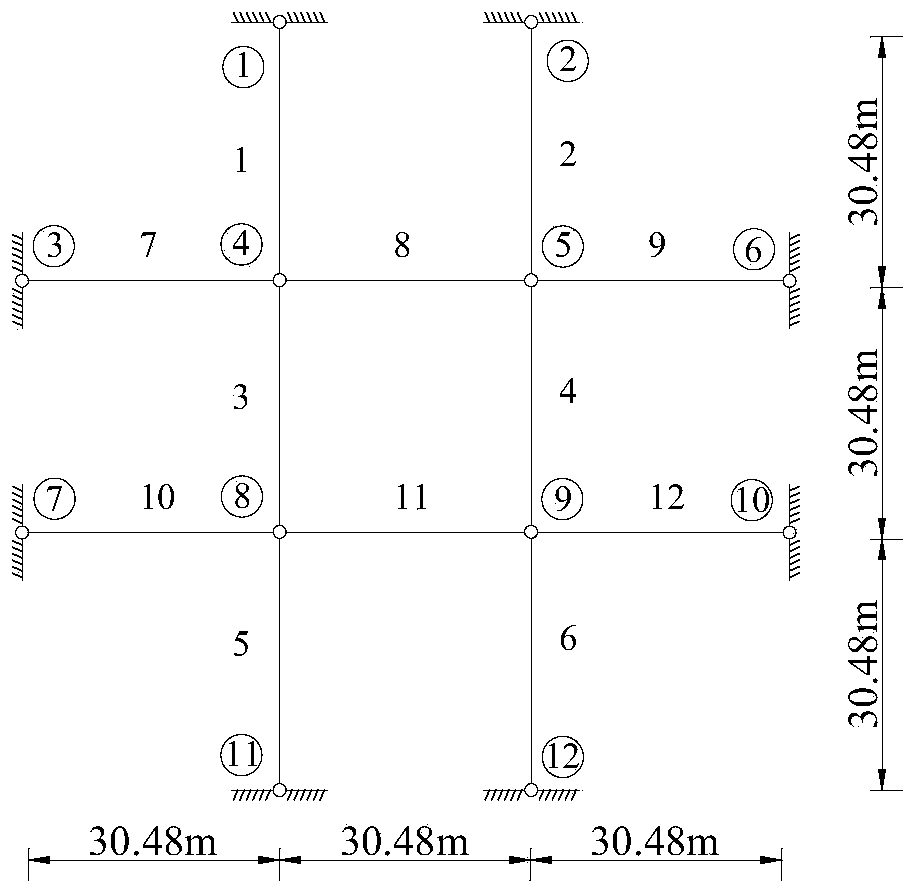

[0032] This embodiment provides a finite element form-finding analysis method for a cable structure, which includes the following steps:

[0033] S1. Establish a broken-line cable structure finite element model, apply a number of concentrated loads on the break points of the finite element model, and solve the initial equilibrium state solution of the cable structure under the prestress and the concentrated load;

[0034] S2. Under the initial equilibrium state solution, continue to superimpose self-weight and / or external load, and solve the working state solution of the cable structure after superimposing the self-weight and / or external load;

[0035] S3. Eliminate the concentrated load, solve the final state solution, and determine the form of the cable structure.

[0036] The establishment of a broken-line finite element model does not require a large number of cable and rod elements, which makes the establishment of the finite element model easier and improves the speed and accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com