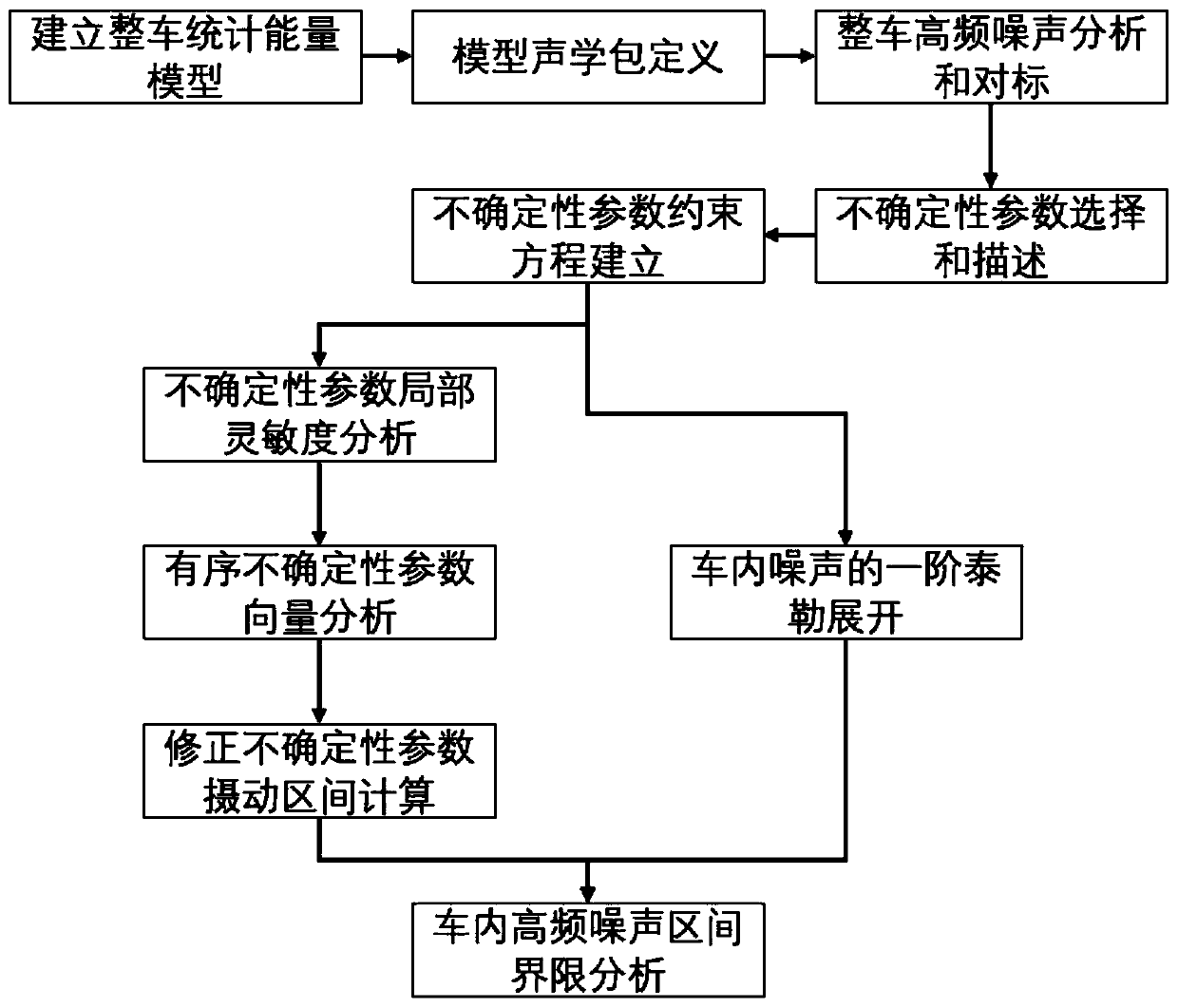

Automobile high-frequency noise prediction method based on correlation interval uncertainty theory

A high-frequency noise and uncertainty technology, used in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as the description of the relationship between uncertain parameters, and achieve the effect of taking into account calculation accuracy and calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The research object of this embodiment is an electric sports utility vehicle with front and rear motors, four-wheel drive, maximum power of 355 horsepower, and peak torsional vibration of 580 Nm.

[0032] Step 1: Establish the statistical energy model of the vehicle. The vehicle statistical energy model includes a structural model composed of 1172 flat subsystems (see attached figure 2 shown) and the acoustic cavity model composed of 80 acoustic cavity subsystems (as attached image 3 shown). Connect various subsystems, including between panels, between panels and acoustic cavities, and between acoustic cavities, to ensure energy transfer between subsystems. According to the structural properties of the whole vehicle panel, the corresponding physical properties are given to the panel.

[0033] Step 2: Use the reverberation chamber sound absorption measurement method to effectively test the sound absorption characteristics of the acoustic package parts. First, measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com