A detection method and device for rapid determination of crude gas composition

A technology of rapid determination and detection method, which is applied in the direction of measuring device, preparation of test samples, material separation, etc. It can solve the problems of inability to measure the correction factor, expensive equipment, and complicated operation. It is suitable for industrial application and equipment cost. Inexpensive, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

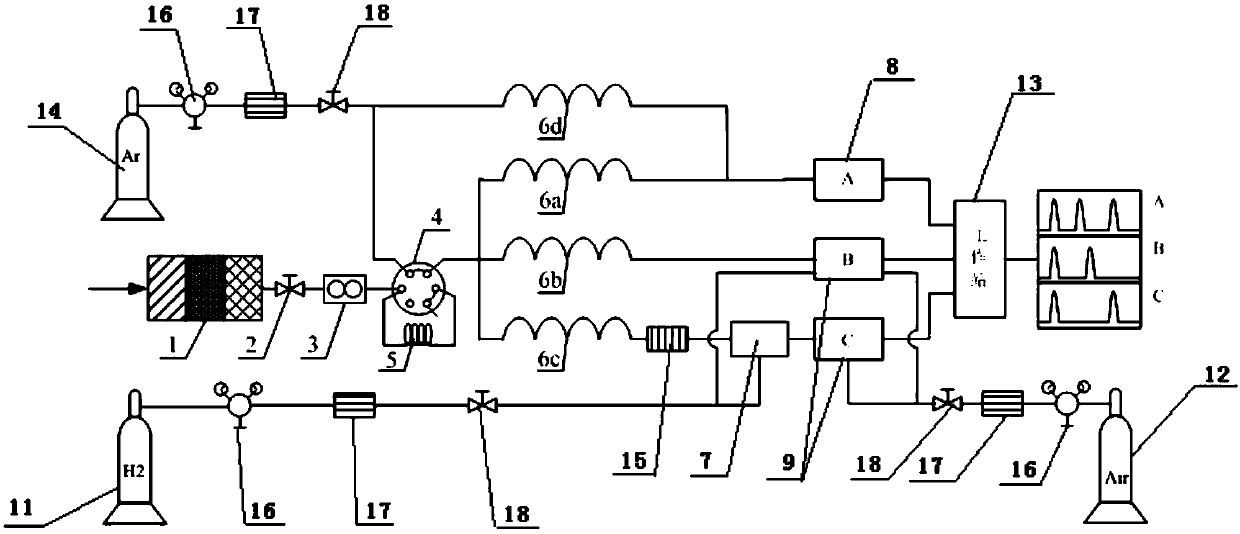

[0048] Such as figure 1 As shown, a device used in a detection method that adopts a rapid determination of crude gas components in this embodiment includes a crude gas purification device 1, an automatic sampling valve 4 with a quantitative loop 5, an argon source 14, 5A ( 13X) Molecular sieve packed column 6a, modified alumina packed column 6b, carbon molecular sieve packed column 6c, reference chromatographic column 6d, methane conversion furnace 7, thermal conductivity detector 8A, hydrogen flame detector 9B, hydrogen flame detector 9C, Hydrogen source 11, air source 12 and work station 13, the air inlet of described coal gas purification device 1 is connected with the crude gas source to be measured, the gas outlet of gas purification device 1 is connected with the automatic sampling valve 4 that is provided with quantitative loop 5 The gas inlet is connected, the gas outlet of the argon source 14 is connected with the gas inlet of the automatic sampling valve 4 of the ref...

Embodiment 2

[0078] The inner diameter of the 5A (13X) molecular sieve packed column of the device used in the detection method for rapid determination of crude gas components in this embodiment is 2mm; the length is 0.5m; the 5A (13X) molecular sieve mesh number is 40 orders; modified alumina The inner diameter of the packed column is 2mm; the length is 0.5m, and 2mol / L KOH, NaOH or NaCO is used for alumina 3 After soaking in an alkaline solution, activate at 300°C for 5 hours; the inner diameter of the carbon molecular sieve packed column is 2mm; the length is 0.5m; the carbon molecular sieve mesh is 40 mesh; other structures are the same as in Example 1.

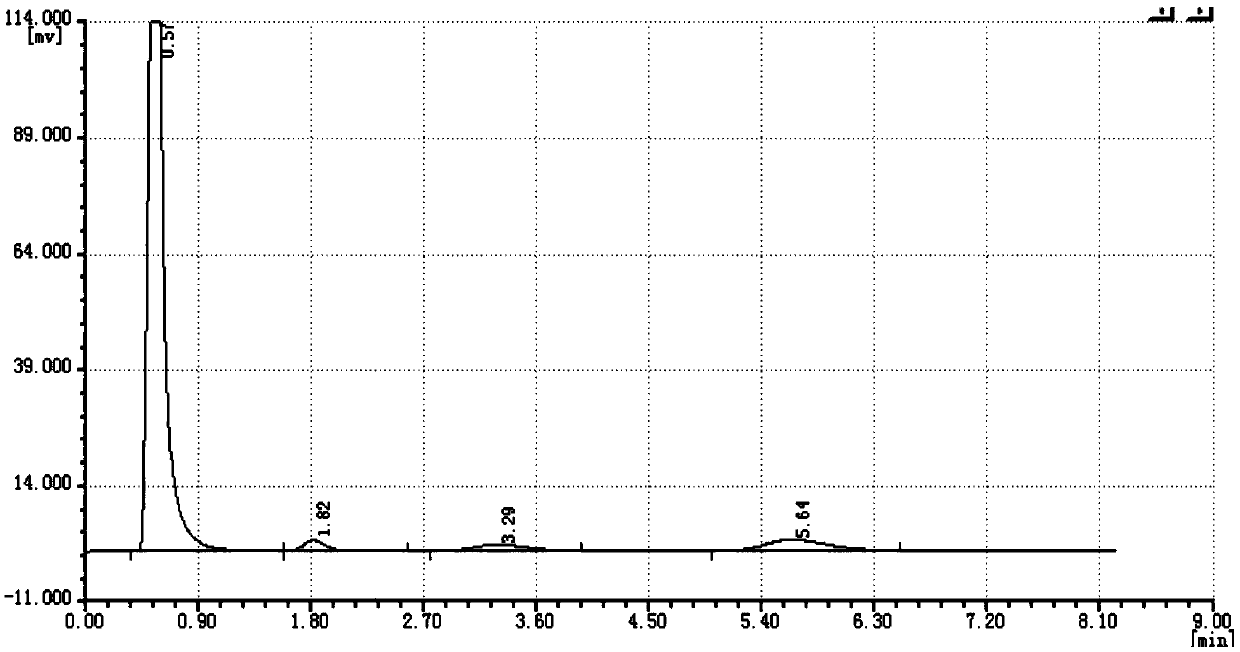

[0079] The detection step of the present embodiment is the same as the detection step of embodiment 1, and the concentration of the gas used for detection in the present embodiment is H 2 4.00%, O 2 5.00%, CO 2 1.00%, CO 2.00%, N 2 88.00%, the chromatographic column is a 5A molecular sieve packed column 6a with an inner diamete...

Embodiment 3

[0093] The internal diameter of the 5A (13X) molecular sieve packed column of the device used in the detection method for rapid determination of crude gas components in this embodiment is 4mm; the length is 6.0m; the 5A (13X) molecular sieve mesh number is 100 orders; modified alumina The inner diameter of the packed column is 4mm; the length is 6.0m, and 10mol / L KOH, NaOH or NaCO is used for alumina 3 After soaking in an alkaline solution, activate it at 500°C for 10 hours; the inner diameter of the carbon molecular sieve packed column is 4mm; the length is 6.0m;

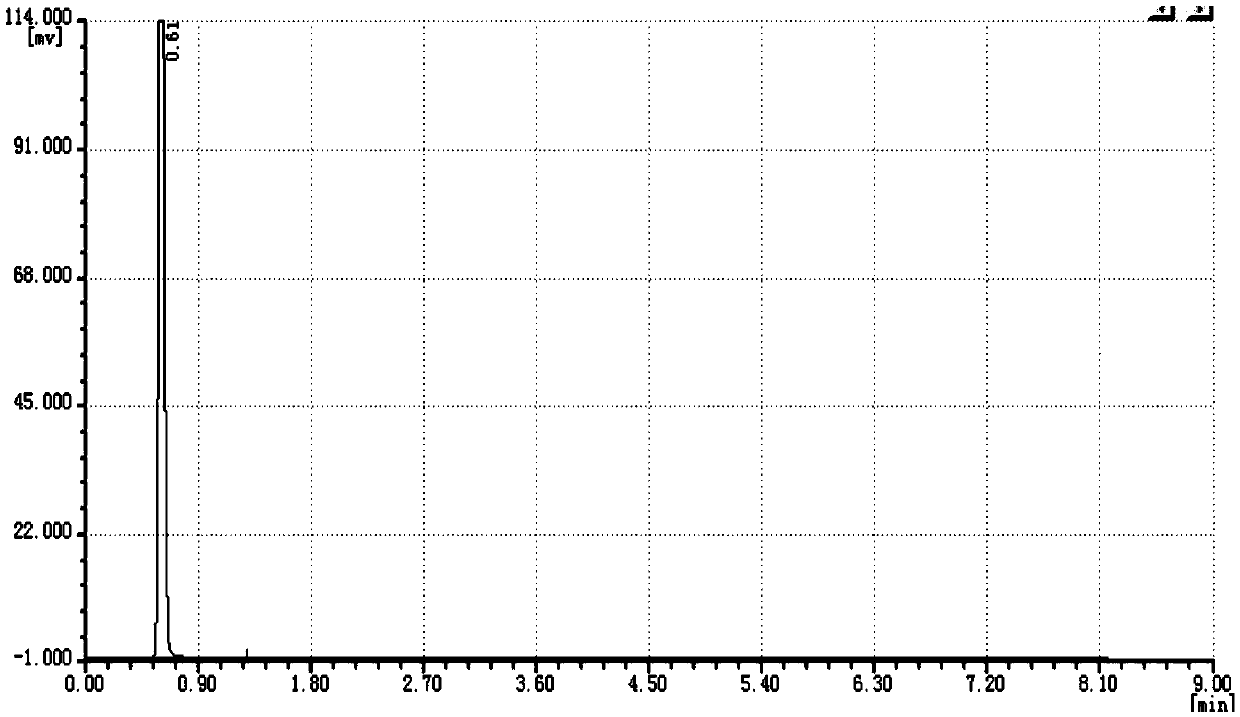

[0094] The detection step of the present embodiment is the same as the detection step of embodiment 1, and the concentration of the gas used for detection in the present embodiment is H 2 0.50%, O 2 1.00%, CO 2 1.00%, CO2.00%, N 2 95.50%, the chromatographic column is a 5A molecular sieve packed column 6a with an inner diameter of 3mm and a length of 3m; the 5A molecular sieve has a mesh number of 80; the modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com