Large-scale carrying belt tearing fault intelligent detection method based on dynamic images

A dynamic image and intelligent detection technology, applied in image enhancement, image analysis, image data processing, etc., can solve problems such as low detection accuracy, rough method, and complex imaging system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

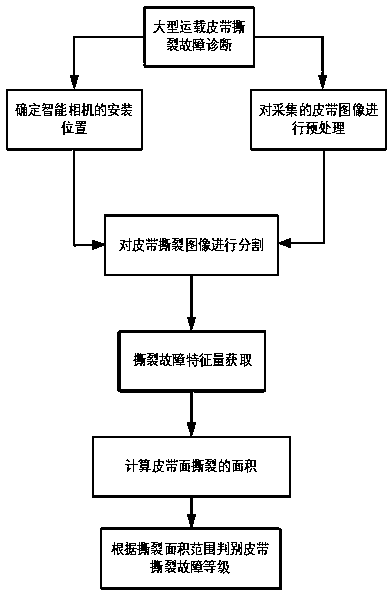

[0050] Such as figure 1 As shown, a dynamic image-based intelligent detection method for large-scale carrier belt tearing faults is used to obtain the belt tearing area and fault level in the carrier belt motion control system. The method includes the following steps:

[0051] Step 1. Determine the installation position of the high-speed industrial camera for the large-scale carrying belt operation system, and collect the belt surface image; the specific steps are:

[0052] Step 1.1. Track the operating status of the large-scale carrier belt, record relevant data, and find the location where the large-scale carrier belt is prone to tearing after analysis. Look for a suitable camera installation near the location to be inspected;

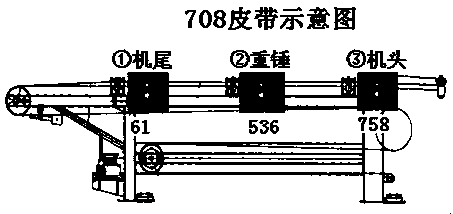

[0053] Step 1.2, such as figure 2 As shown, determine the installation position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com