Train control method and device for ground automatic passing-over of split phase

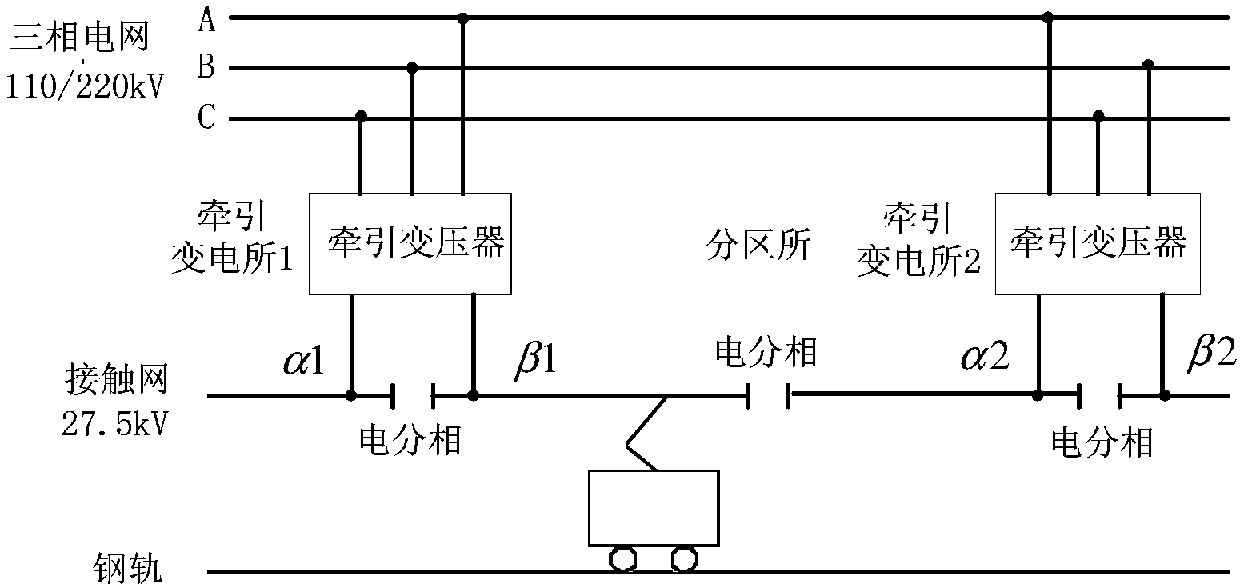

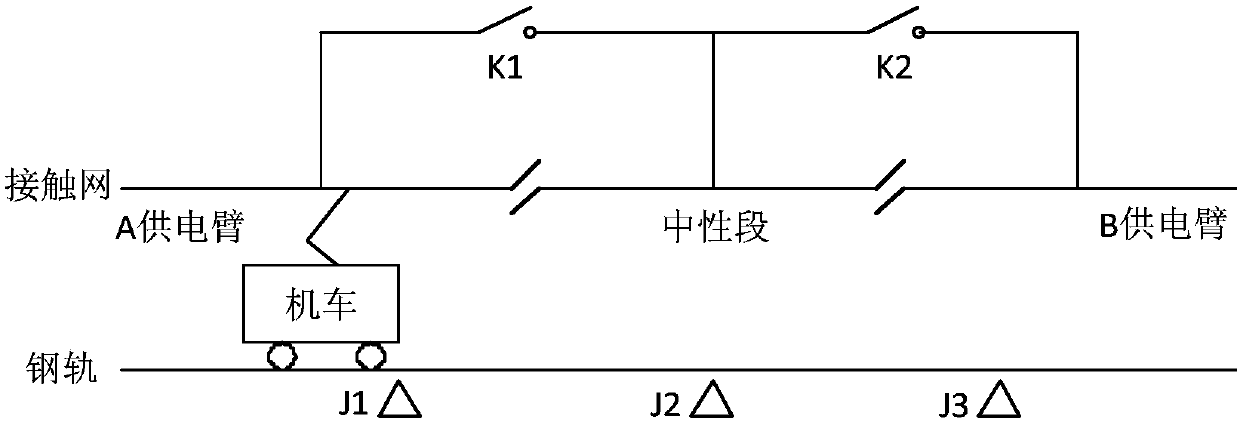

An automatic phase separation and train control technology, which is applied to motor vehicles, electric vehicles, control drives, etc., can solve the problems that the performance of the ground automatic phase separation device cannot be fully utilized, the recovery time of traction force is long, and the time of traction force loss is long. To achieve the effect of shortening the time when the train loses traction, avoiding speed loss, and improving transport capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

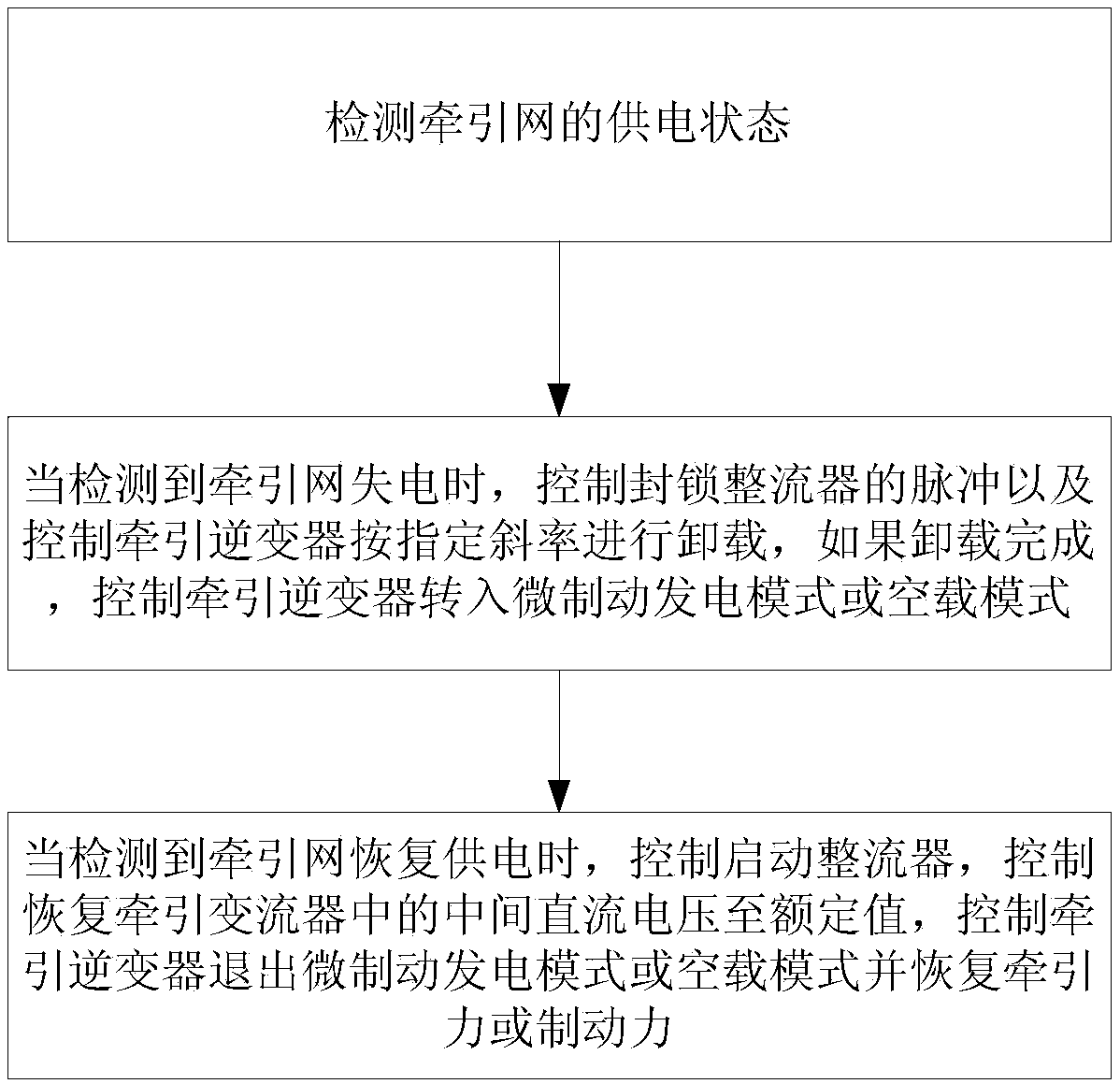

[0055] like image 3 As shown, the train control method used in this embodiment for automatic phase separation on the ground includes detecting the power supply state of the traction network in real time during the phase separation process of the train, and controlling the traction converter according to the detected power supply state of the traction network according to the first control mode The first control mode is to control the blockage of the rectifier and unload the traction inverter when it is detected that the traction network is powered off, and resume the rectifier and traction inverter when it is detected that the traction network is restored to power supply traction or braking force of the engine.

[0056] For example, the dead time of the electronic switch ground automatic phase separation device is relatively shorter, in order to adapt to the shorter dead time of the ground automatic phase separation device, the control object of the train control method in th...

Embodiment 2

[0093] This embodiment is basically the same as Embodiment 1, except that this embodiment controls the traction converter according to the detected power supply state of the traction network according to the second control mode, and the second control mode is when the traction network is detected to be powered off The control blocks the rectifier and the traction inverter, and when it is detected that the power supply of the traction network is restored, the control resumes starting the rectifier and controlling the traction inverter to resume traction or braking force after restarting with residual magnetism.

[0094] The steps of controlling the traction converter in the second control mode of this embodiment include:

[0095] When the power failure of the traction network is detected, the control blocks the pulses of the rectifier, traction inverter and auxiliary converter;

[0096] When it is detected that the power supply of the traction network is restored, the rectifier...

Embodiment 3

[0100] The present embodiment is used for the train control device that the ground automatically crosses the phase and comprises:

[0101] A power supply status detection module is used to detect the power supply status of the traction network in real time;

[0102] The control module is configured to control the traction converter according to the first control mode or the second control mode according to the detected power supply state of the traction network, including a first control unit configured to control the traction converter according to the first control mode, when When it is detected that the traction grid is powered off, it is controlled to block the rectifier and unload the traction inverter, and when it is detected that the traction grid resumes power supply, the rectifier and the traction force or braking force of the traction inverter are restored; and the second control unit is used for According to the second control mode, the traction converter is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com