Granular activated charcoal washing equipment

A technology of granular activated carbon and washing equipment, applied in the fields of carbon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of low efficiency, inconvenient repeated rinsing, insufficient washing, etc. Washing quality, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

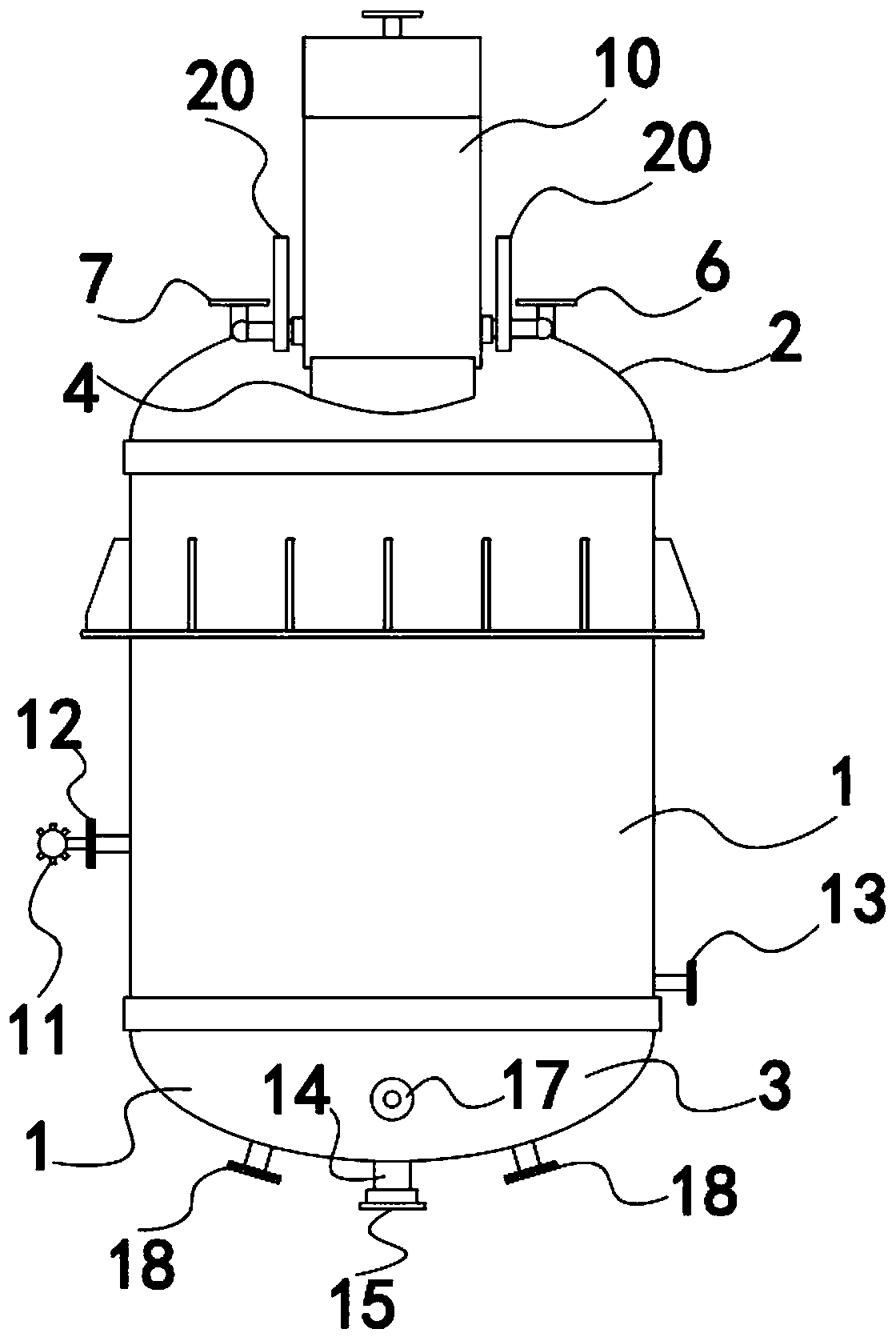

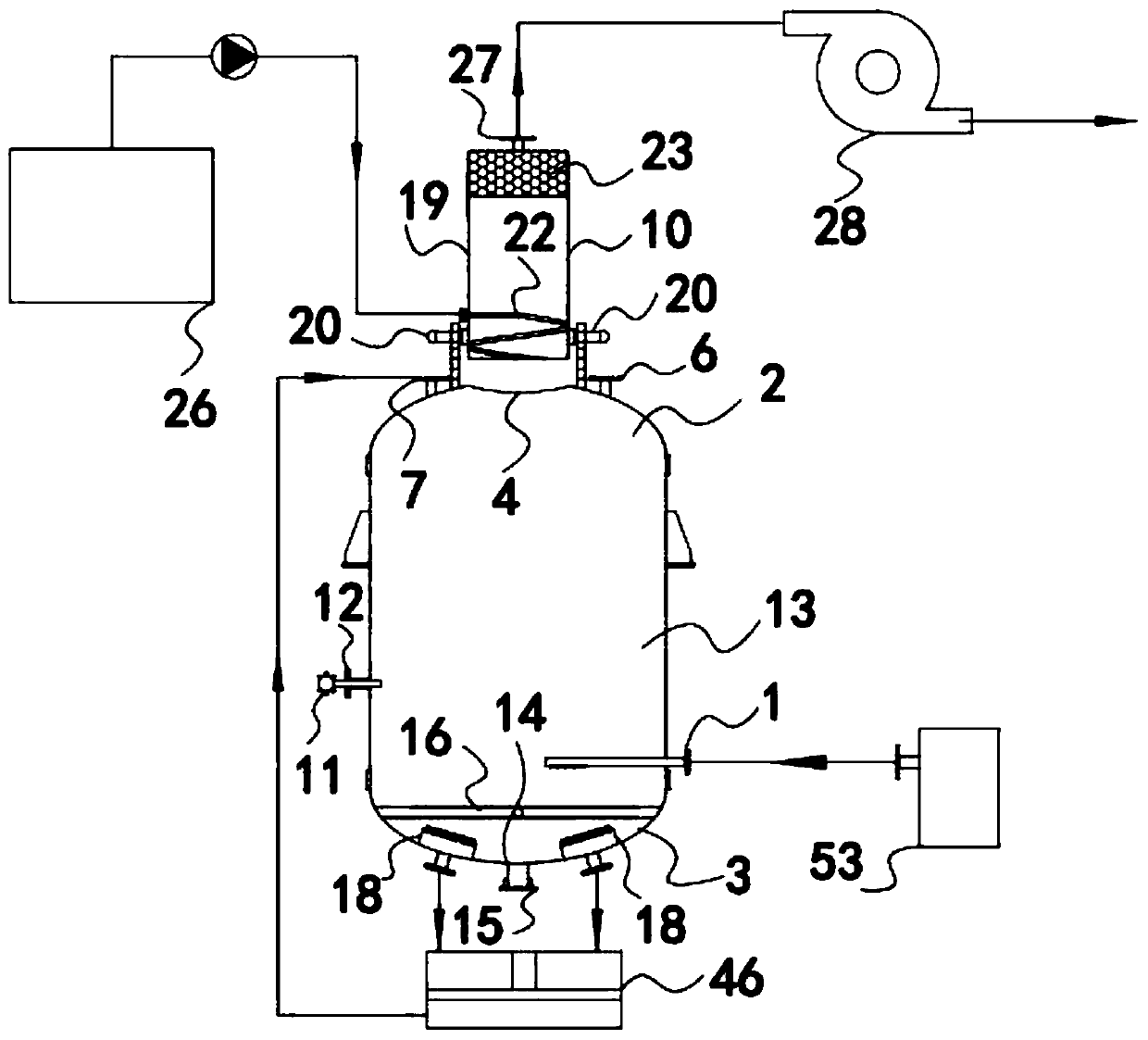

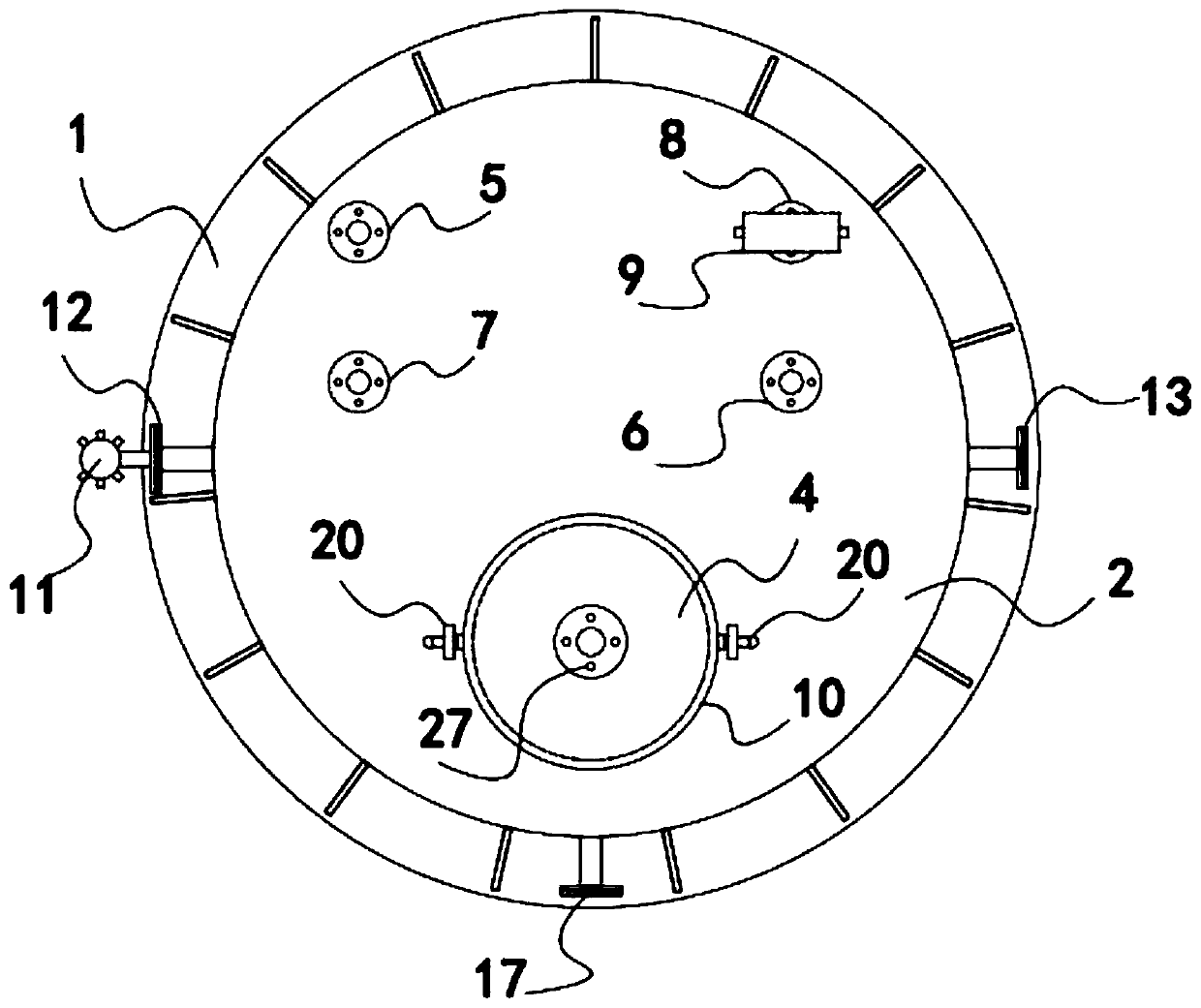

[0032] Such as figure 1 As shown, a granular activated carbon washing equipment includes a tank body 1, and an upper head 2 and a lower head 3 arranged at the upper and lower ends of the tank body 1, the tank body 1 is cylindrical, and the upper head 2 and the lower head 3 It is arc-shaped. Such as image 3 As shown, the upper head 2 is provided with a feeding port 4 for adding granular activated carbon, a clear water inlet 5 for passing water into the tank body 1, and an acid liquid port 6 for adding acid liquid to the tank body 1. The circulating water inlet 7 for post-rinsing treatment into the tank body 1, the liquid level detection port 8 for quantitatively adding acid liquid, and the liquid level control device for quantitative acid liquid connected to the liquid level detection port 8 9. The liquid level control device 9 adopts the linkage control device of the float liquid level switch (FK2-normally open) and the high liquid level alarm, and the purification device 1...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, the difference is:

[0042] Such as Figure 4 and 5 As shown, the purification device 10 also includes a solid particle intercepting mechanism 21, the solid particle intercepting mechanism 21 is horizontally arranged on the circular boss 24 in the middle and lower part of the air cylinder 19, and the solid particle intercepting mechanism 21 includes a filter disc 34, a hinged ball 35 , L-shaped locking rod 36, and an upper locker 37 and a lower locker 38 for clamping the L-shaped locking rod 36, and a reverse osmosis filter membrane 39 coated with antiscalant on the front and back sides of the filter disc 34, When the wetted dust is intercepted on the reverse osmosis filter membrane 39, because the reverse osmosis filter membrane 39 has good scale resistance and hydrophobicity, the wetted dust is not easy to gather and block the filter disc 34, usually without Under the condition of sufficient adhesion support, it...

Embodiment 3

[0047] This embodiment is basically the same as Embodiment 2, the difference is:

[0048] Such as Figure 9As shown, the upper surface of the annular aeration ring 47 is vertically and equidistantly connected with three aeration pipes 48, the three aeration pipes 48 communicate with the interior of the annular aeration ring 47, and the annular aeration ring 47 is provided with several upper aeration pipes. The nozzle 49 and the lower aeration nozzle 50 are provided with a left aeration nozzle 51 and a right aeration nozzle 52 which are staggered up and down on the aeration pipe 48 . As an improvement of the previous technical solution, the single annular aeration ring 47 is fixed in the opening direction of the aeration holes, and can only be aerated and stirred in the longitudinal plane, and it is not easy to cover the material below the annular aeration ring 47, so There are more dead angles for mixing. For this reason, on the annular aeration ring 47, the aeration nozzles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com