Preparing method and application of rust inhibitor

A rust inhibitor and reaction technology, applied in the field of rust inhibitor preparation, can solve the problems of toxic materials, polluted environment, difficult application, etc., and achieve the effects of good appearance and good yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

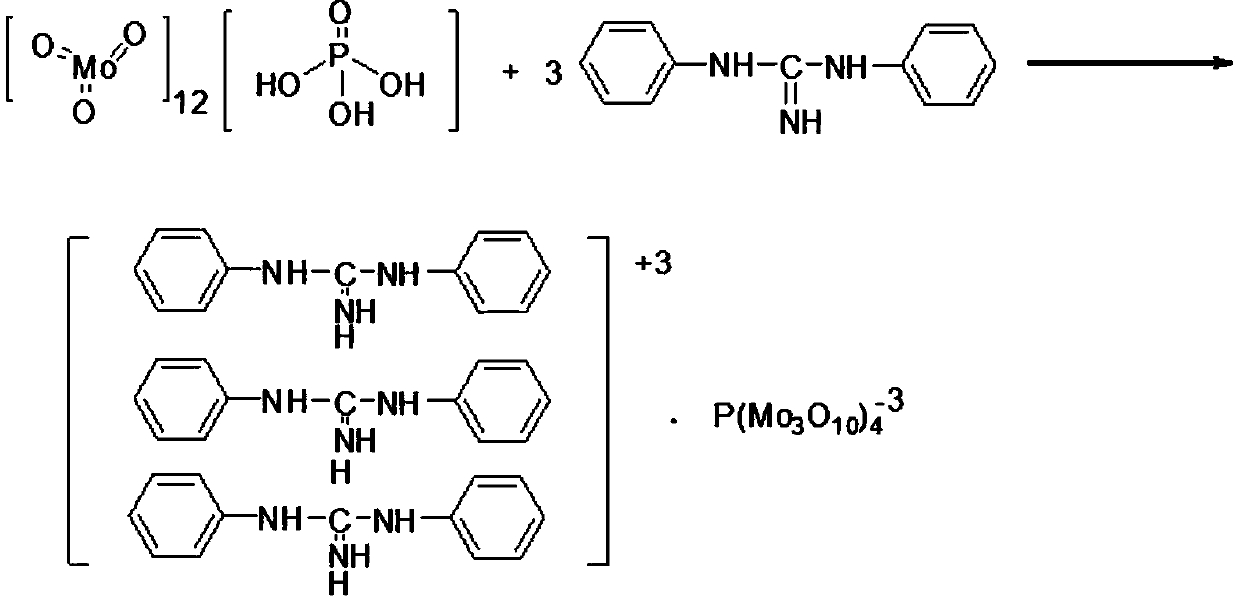

[0020] In order to overcome the defects of the above-mentioned diphenylguanidine chromate existing in the prior art, the main train of thought of the embodiments of the present invention is that a preparation method and application thereof of an antirust agent comprise the steps:

[0021] The phosphomolybdic acid solid is dissolved in water to obtain a phosphomolybdic acid solution, and the diphenylguanidine solid is slowly dissolved in water to obtain a diphenylguanidine slurry;

[0022] Under the stirring state, slowly add diphenylguanidine slurry into the dissolved phosphomolybdic acid solution for reaction. The reaction temperature is 20-50°C. As the reaction progresses, the color of the precipitate produced gradually changes from orange to yellow, and the particles When the product becomes thinner and reaches the end of the reaction, the obtained product is suction-filtered, and the filter cake is dried at 70-75°C to obtain the pure product.

[0023] Among them, the synth...

Embodiment

[0028] Dissolve 5.00g (2.71mmol) of phosphomolybdic acid in 20ml of distilled water, slowly dissolve 1.77g (8.37mmol) of diphenylguanidine in 10ml of distilled water, and slowly add diphenylguanidine slurry under high-speed stirring for reaction. The color of the resulting precipitate gradually changed from orange to yellow, and the particles became finer. When the end point of the reaction is reached, the product is filtered with a suction filter, and the filter cake is dried in an infrared dryer at 70-75°C to obtain the product.

[0029] The reaction formula is as follows:

[0030]

[0031] Next, set different temperatures, different reaction times in different embodiments and carry out experiment, obtain the product of different yields. The specific parameters are shown in Table 1 below.

[0032] Table 1

[0033]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap