A kind of continuous preparation method of porous composite ionic membrane

A composite ion and ion membrane technology, applied in the field of all-vanadium redox flow batteries, can solve the problems of high vanadium ion permeability of perfluorosulfonic acid proton exchange membrane and low production efficiency of diaphragm preparation process, and achieve good ion selection Permeability, good electrical conductivity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

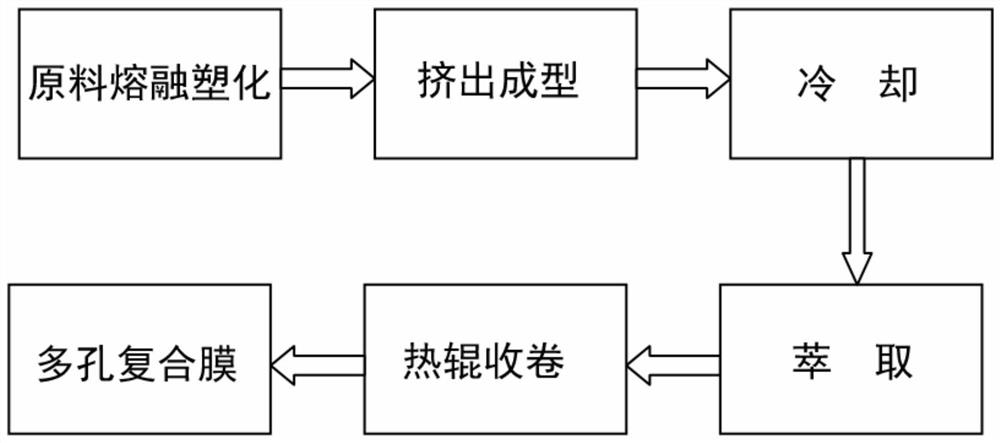

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 12kg of perfluorosulfonic acid resin and 2.6g of polybenzimidazole resin in dimethylacetamide (DMAC), heat and stir at 200°C for 5-8 hours to form a gel, add dibutyl phthalate Add 180mL of ester into the gel mixture, stir for 3.5 hours and vibrate in an ultrasonic oscillator for 1h~2h to refine the solution and drive out the tiny bubbles in it, put the gel mixture into the extruder, and pass through the mill Mushroom is extruded at 180°C, and then the film is cooled in three temperature sections of 180-200°C, 100-140°C, and 60-80°C in sequence. The treatment time of each temperature section is 0.5h, and the film after cooling treatment enters Extraction is carried out in a mixed extractant of ethanol and water, the membrane is taken out and washed with deionized water, the ion exchange membrane is dried at 70-90°C, and the dried membrane is hot-pressed to obtain a porous ion-exchange composite membrane.

[0030] The relevant performance data of the present embo...

Embodiment 2

[0033]Dissolve 12kg of perfluorosulfonic acid resin and 2.6g of polyvinylidene fluoride resin in dimethylacetamide (DMAC), heat and stir at 200°C for 5-8 hours to form a gel, and add 180mL of polyvinylpyrrolidone to the In the gel-like mixture, stir for 4 hours and vibrate in an ultrasonic oscillator for 1h-2h to refine the solution and drive out the tiny bubbles in it, put the gel-like mixture into the extruder and extrude through the mold at 180°C After forming, the film enters three temperature sections of 180-200°C, 100-140°C, and 60-80°C for cooling treatment. The treatment time of each temperature section is 0.5h, and the film after cooling treatment enters the mixed solution of ethanol and water Extraction is carried out, the membrane is taken out and washed with deionized water, and the ion exchange membrane is dried at 70-90° C., and the dried membrane is hot-pressed and wound to obtain a porous ion-exchange composite membrane.

[0034] The relevant performance data o...

Embodiment 3

[0037] Dissolve 12kg of perfluorosulfonic acid resin and 2.6g of polyvinylidene fluoride resin in dimethylacetamide (DMAC), heat and stir at 200°C for 5-8 hours to form a gel, and add 180mL of polyvinyl alcohol PVA Put it into the gel-like mixture, stir for 3 hours and vibrate in an ultrasonic oscillator for 1h~2h to refine the solution and drive out the tiny bubbles in it, put the gel-like mixture into the extruder and pass through the mold at 180°C Extrusion molding, and then the film is sequentially entered into three temperature sections of 180-200°C, 100-140°C, and 60-80°C for cooling treatment. The treatment time of each temperature section is 0.5h. Extraction is carried out in a mixed extractant, the membrane is taken out and washed with deionized water, and the ion exchange membrane is dried at 70-90° C., and the dried membrane is hot-pressed and wound to obtain a porous ion-exchange composite membrane.

[0038] The relevant performance data of the present embodiment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com