A double-sided boring and milling machine based on the principle of fixed axis layering

A boring and milling machine and principle technology, applied in the field of milling machines, can solve the problems of the lifting shaft being prone to limit, the inability to process and adjust the end of the workpiece, and achieve the effect of increasing the processing range, reducing the volume difference and reducing the risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

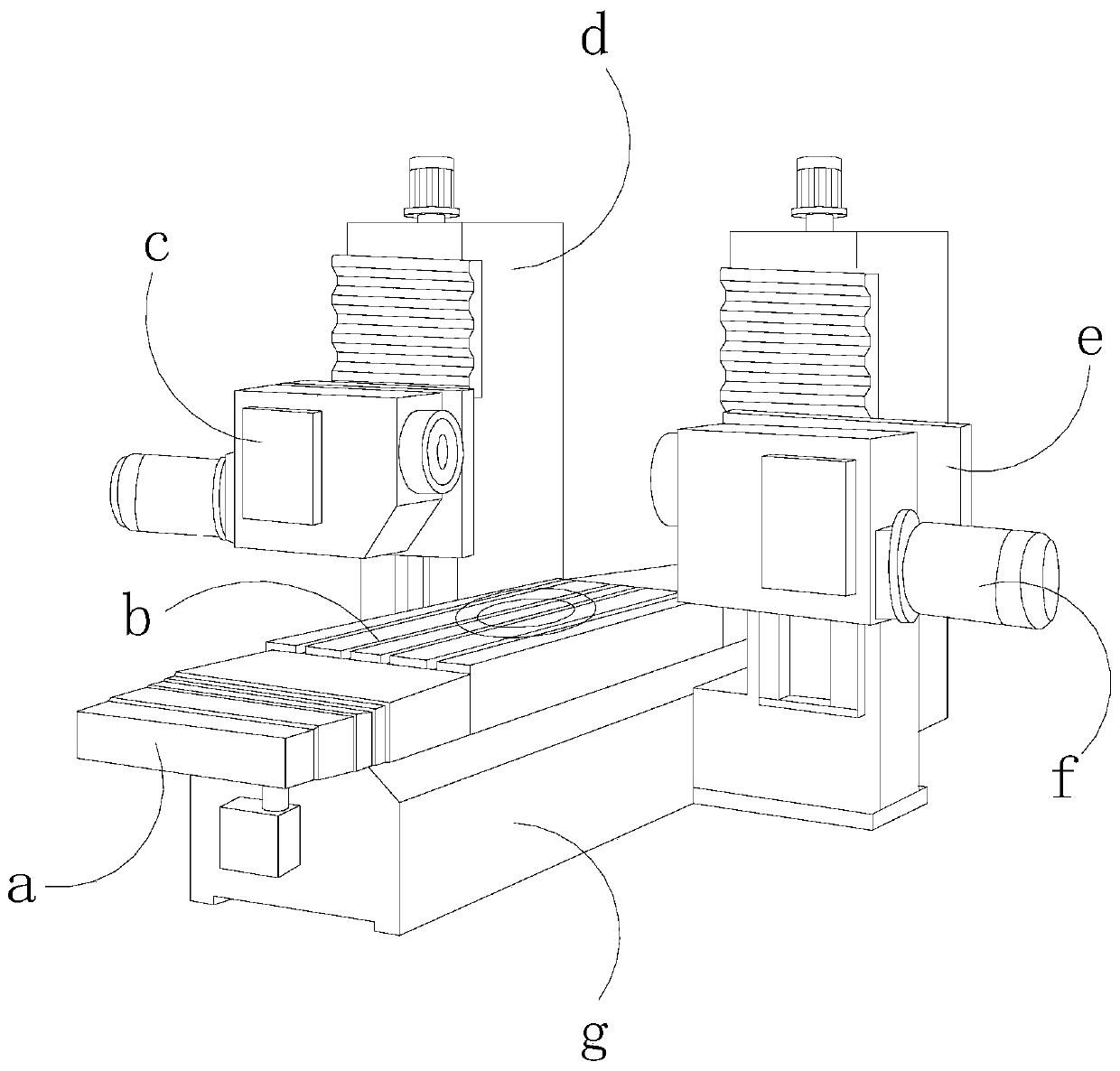

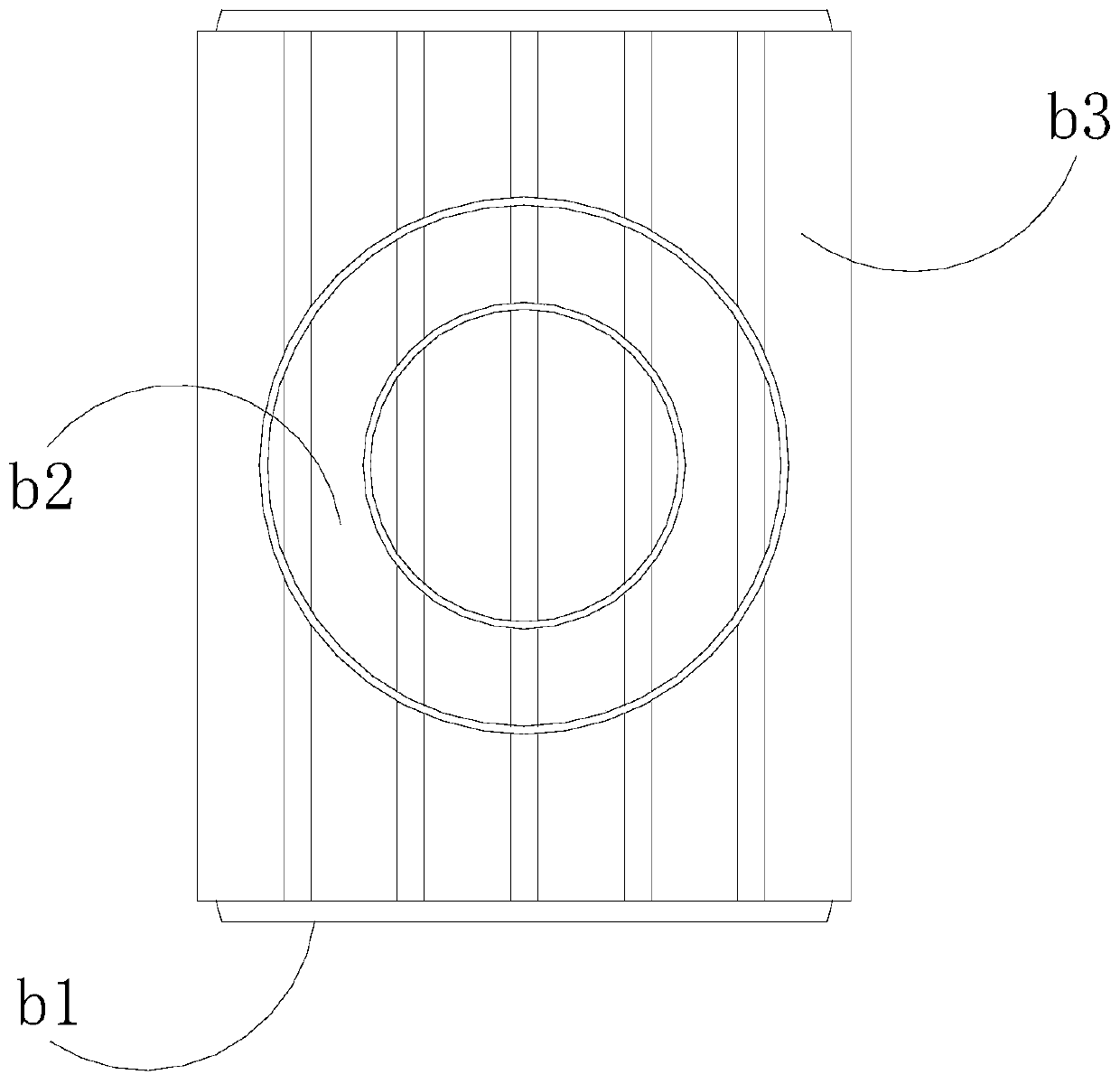

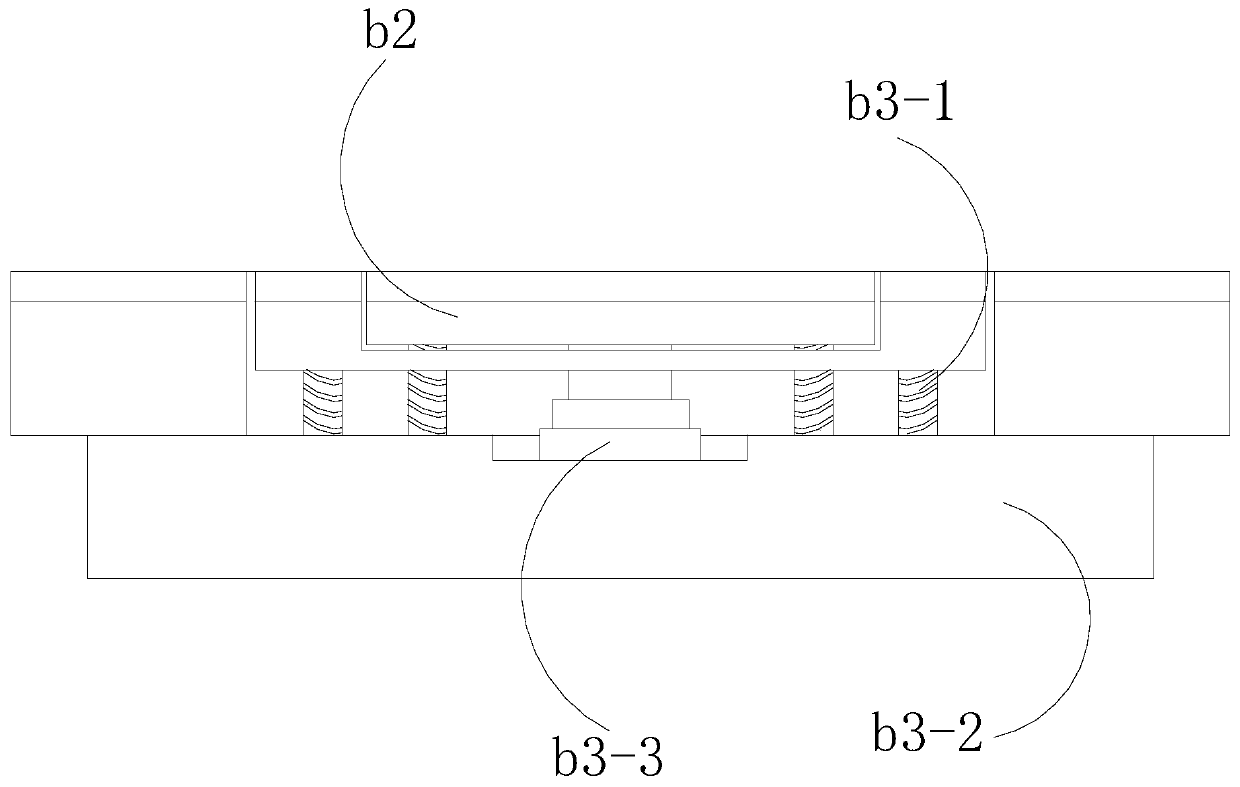

[0030] see Figure 1-Figure 7 , the present invention provides a double-sided boring and milling machine based on the principle of fixed axis layering, the structure of which includes a feed ram a, a processing platform b, a boring and milling spindle c, a column d, a lifting plate e, a spindle motor f, and a fixed base g , the bottom of the feed ram a is installed on the top of the fixed base g by buckling, the left and right sides of the fixed base g are respectively provided with columns d, and the front end of the column d is connected with the lifting plate e by buckling, There are two boring and milling spindles c, which are respectively fitted with the lifting plate e, the first and last ends of the processing platform b are set in the middle of the feed ram a by fastening, and the spindle motors f are respectively connected through On the outside of the boring and milling spindle c, the workpiece to be processed is positioned on the processing platform b, and then can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com