Polycrystalline diamond ball grinding machining method

A technology of polycrystalline diamond and diamond abrasive paste, which is applied in metal processing equipment, grinding devices, grinding machine tools, etc., and can solve the problems of polycrystalline diamond balls that cannot meet the standard of roundness and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

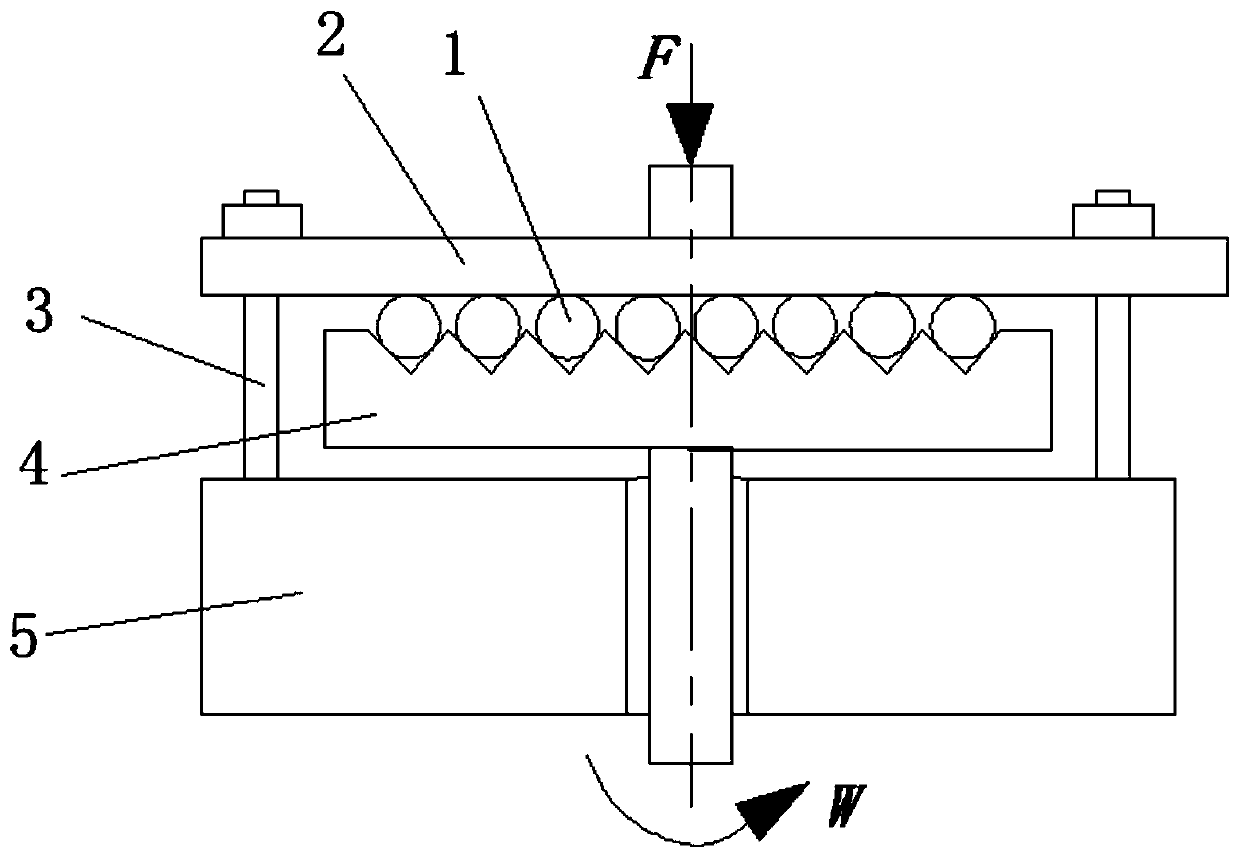

[0025] A kind of polycrystalline diamond ball grinding processing method, comprises the following steps:

[0026] Coarse grinding:

[0027] Step 1: Evenly apply a layer of diamond grinding paste with a thickness of 0.6mm on the V-shaped groove of the lower grinding disc 4 and the bottom surface of the upper grinding disc 2. The particle size of the grinding paste is W14, and the material of the upper and lower grinding discs is cemented carbide.

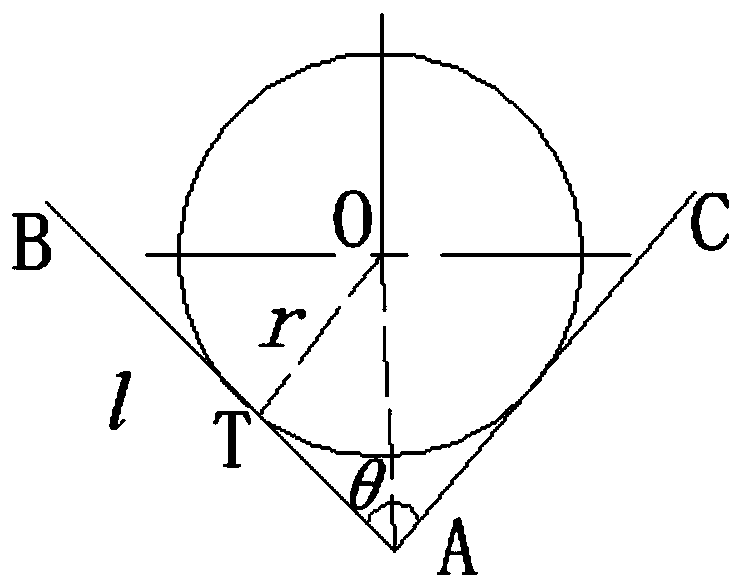

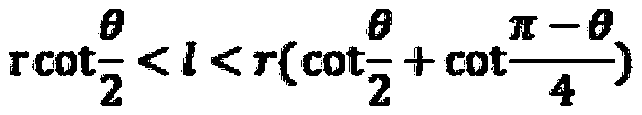

[0028] Step 2: Put the polycrystalline diamond ball 1 with a radius r of 0.5mm into the V-shaped groove of the lower grinding disc 4, wherein the included angle θ in the V-shaped groove is 90°, and the side length l is 0.7mm.

[0029] Step 3: The upper grinding disc 2 is connected to the equipment base 5 through the guide post 3, and a pressure is applied on its upper surface at the same time, so that the pressure on a single polycrystalline diamond ball is 28N.

[0030] Step 4: Keep the upper grinding disc 2 fixed, and the lower gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com