Aggregate and concrete integrated production system

A production system and concrete technology, applied in the field of concrete, to achieve the effect of improving effectiveness, saving manpower and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

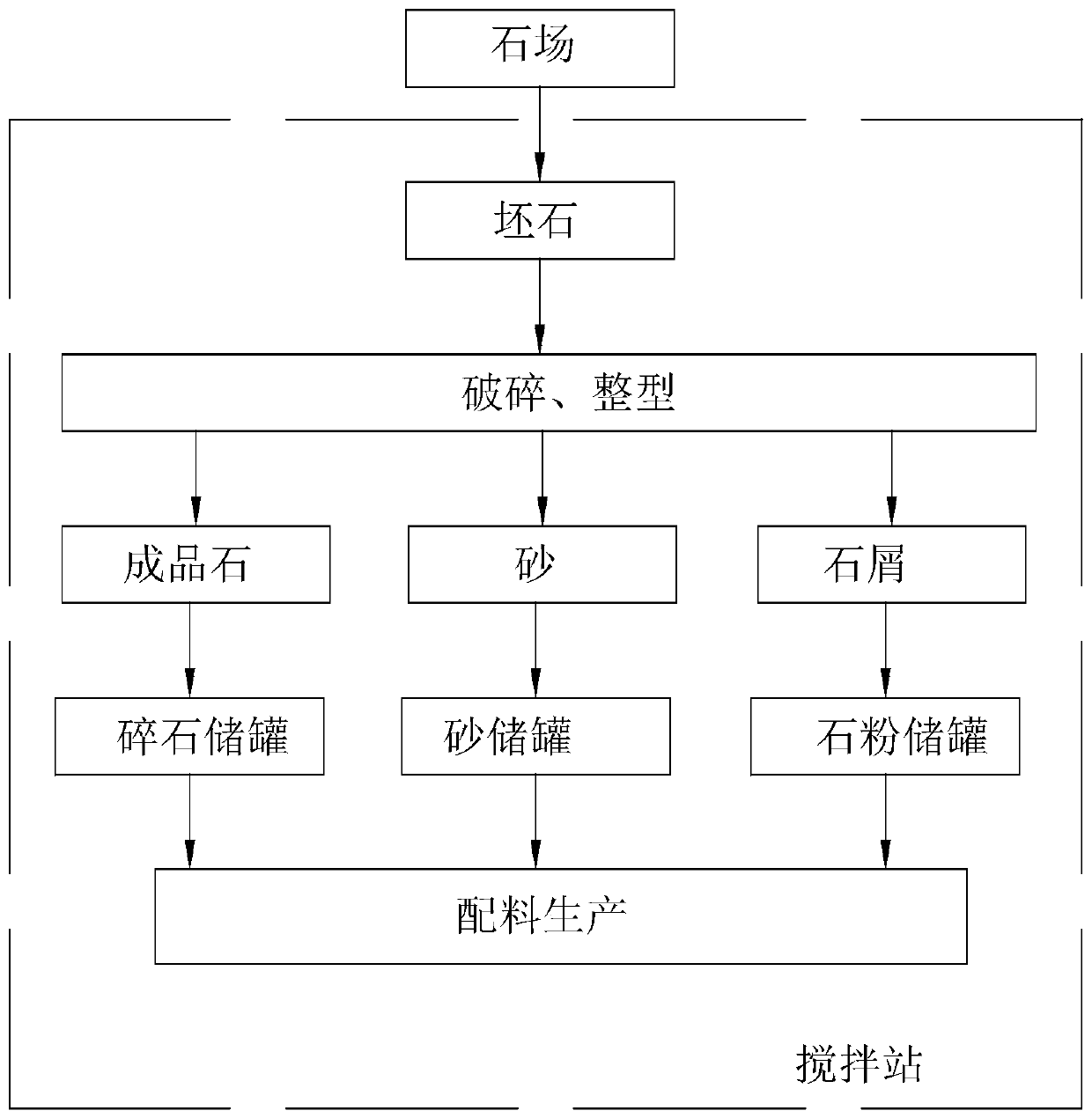

[0032] refer to figure 1 In the aggregate and concrete integrated production system shown, the method includes:

[0033] 1) Recover the rough stone from the quarry and crush the green stone;

[0034] 2) Shaping the broken rough stones to make finished stones, sand and stone chips;

[0035] 3) Store the finished stone, sand and stone chips separately;

[0036] 4) The crushing, shaping, and storage of the rocks are combined in the same mixing station for joint production.

[0037] In the embodiment, the steps of making finished stones, sand and stone chips are processed in a trinity in the same mixing station, and each processing procedure is seamlessly connected and intensively managed. The finished stones, sand and stone chips are respectively stored off the ground in storage tanks, that is, the storage tanks for storing finished stones, sand and stone ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com