Mold with movable mold cavities

A technology of movable cavity and mould, which is applied in the field of moulds, can solve the problems of uneven thickness, difficult molding, large internal stress, etc., and achieve the effects of not easy to separate from each other, easy to flow, and good internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The mold with movable cavity of the present invention is suitable for producing thin-walled products, battery back covers, mobile phone shells or optical products, and the materials used are high-viscosity materials or low-viscosity materials, composite materials that are not easy to separate from each other or easy to separate from each other composite material.

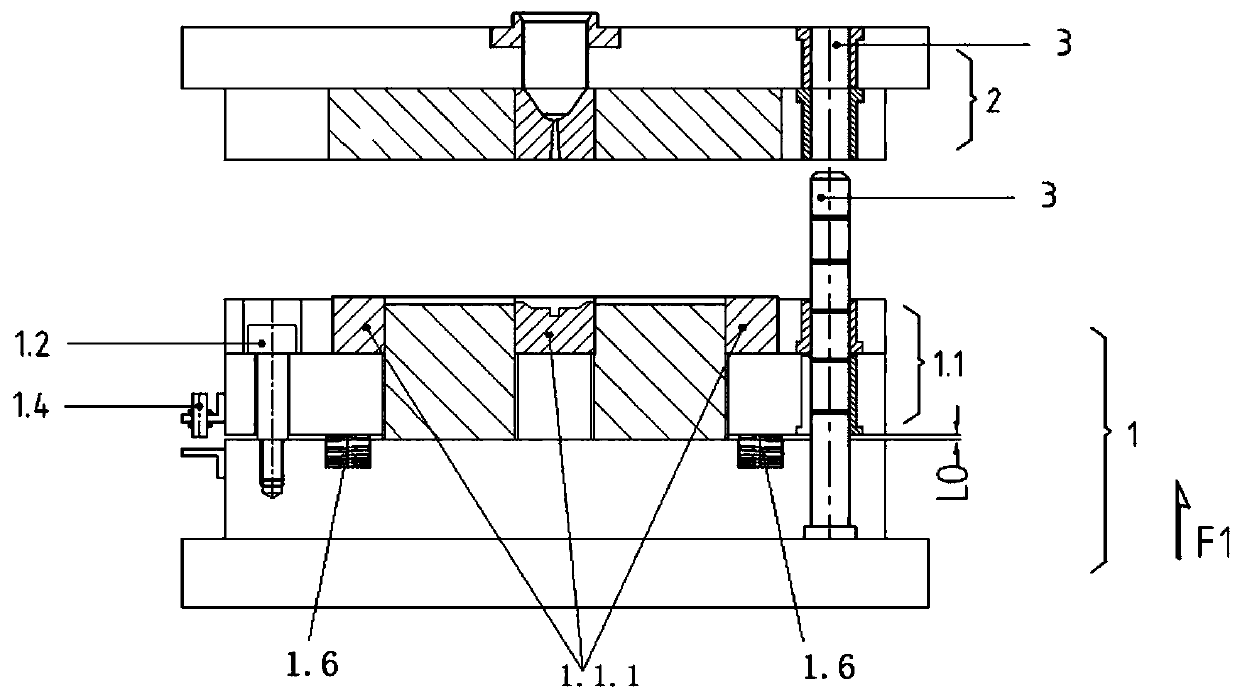

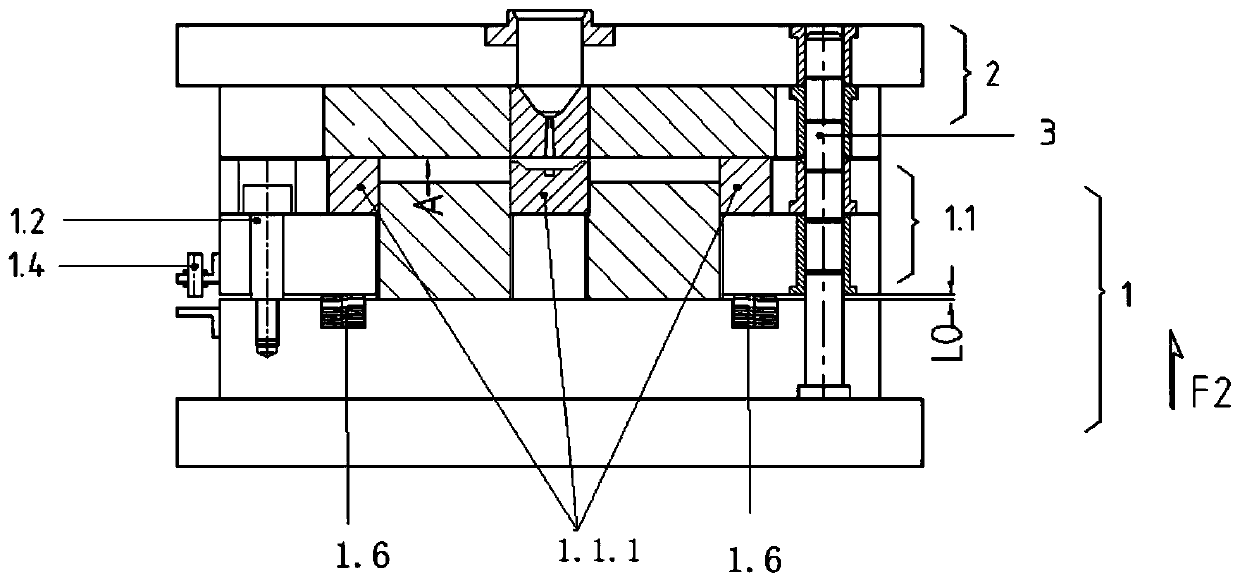

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 , the preferred embodiment and other embodiments of the mold with movable cavity of the present invention are described in detail.

[0033] The invention provides a mold with a movable cavity, which includes a movable mold 1 and a fixed mold 2, the movable mold 1 is provided with a movable mold support device 1.10, and the fixed mold 2 is provided with a fixed mold support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com