Micro-nano injection molding mold cavity heating system and heating method thereof

An injection molding and heating system technology, applied in the field of polymer molding, can solve the problems of inaccurate cavity temperature control and large heat loss, and achieve the effects of improving friction heat generation efficiency, increasing shear friction, and avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

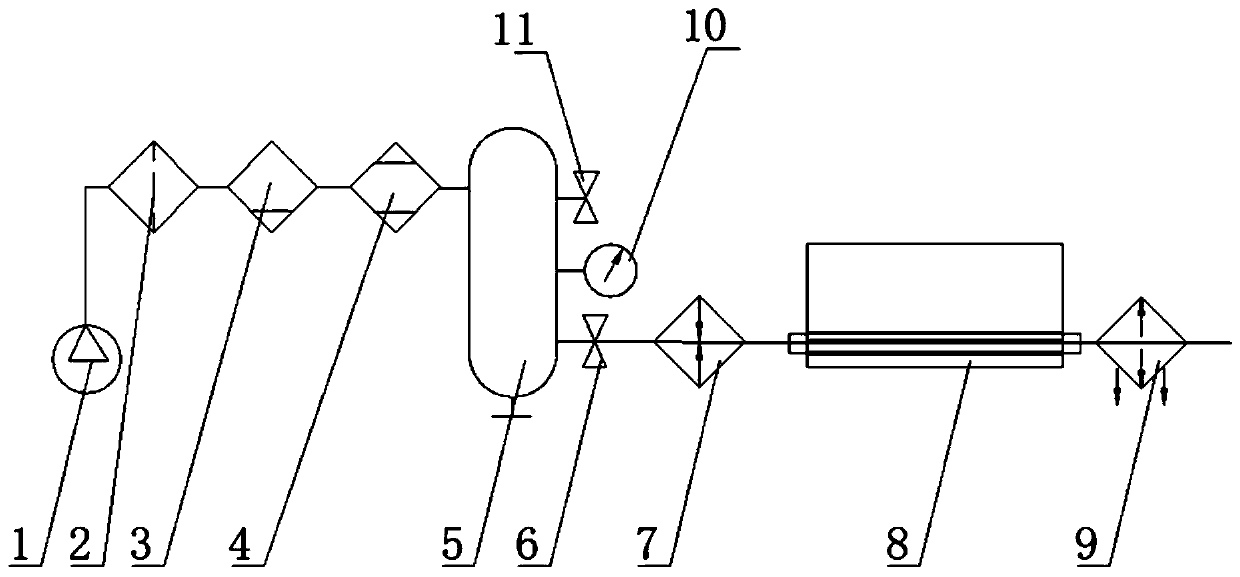

[0027] Specific Embodiment 1: In this embodiment, a micro-nano injection molding mold cavity heating system includes an air compressor 1, a filter 2, a water separator 3, an air dryer 4, an air storage tank 5, a ball valve 6, and a heater 7. Mold insert with holes 8, cooler 9; wherein, the air compressor 1 communicates with the air inlet of the filter 2, the air outlet of the filter 2 communicates with the air inlet of the water separator 3, and the air outlet of the water separator 3 It is connected with the air inlet of the air dryer 4, the air outlet of the air dryer 4 is connected with the air inlet of the air storage tank 5, the air outlet of the air storage tank 5 is connected with the air inlet of the heater 7, and the connection between the air storage tank 5 and the heater 7 A ball valve 6 is arranged between them, and the air outlet of the heater 7 communicates with the air inlet of the mold insert 8 with holes, and the air outlet of the mold insert 8 with holes commu...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: when the mold insert 8 with holes has multiple through holes, the multiple through holes are arranged in a single row, parallel to the bottom edge of the mold insert, and the hole spacing is 3~5mm. Others are the same as in the first embodiment.

[0030] In this embodiment, a plurality of through holes are provided to further realize uniform heating of the mold cavity and improve the heating effect.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the through hole is 6-10 mm away from the bottom of the mold cavity. Others are the same as in the first or second embodiment.

[0032] In this embodiment, the distance between the through hole and the bottom of the mold cavity is 6-10 mm, so as to ensure that the rigidity and strength of the mold insert meet the molding requirements when the melt is filling the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com