A spring energy storage jumping mechanism

An energy storage, spring shaft technology, applied in the field of robotics, can solve problems such as overall structure rotation, increasing overall structure and control program complexity, and non-uniform spring compression speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below with reference to the accompanying drawings.

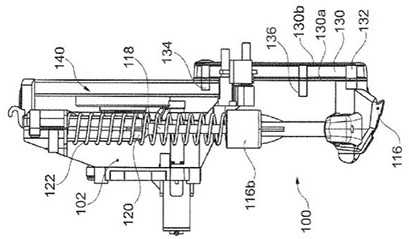

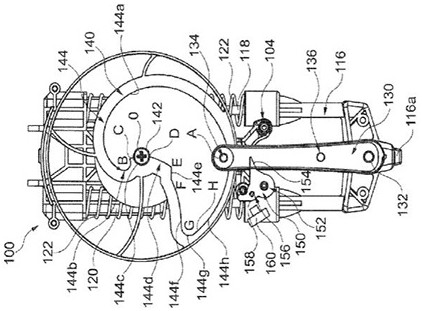

[0026] figure 1 and 2 Shows a jump mechanism described in US 20150352454 A1, the entire structure represented by reference numeral 100.

[0027] The structure 116 comprises a sliding portion, the sliding portion 116 is rigidly secured to the rods 118 and slidably received in the base 102 integrally with the two cylinders 120. For two energy storage spring 122 and 118 respectively around the two rods placed in their respective cylinders 120, one end 116b is supported on a shoulder formed at the sliding portion 116 coaxially with rod 118, the rod 118 of the root . Upper shoulder 104 formed on the cylinder 120, the opposite of the hole opposite thereto, an end portion 118 joined by respective rod.

[0028] When the sliding portion 116 moves closer to the base of the carriage 102 when the compression spring accumulator, when the sliding portion 116 slides backward, the spring pushing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com