Conductive cloth adhesive tape

A technology of conductive cloth and tape, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of weak bonding strength at high temperature, insufficient electrical conductivity, and poor anti-friction performance, and achieve enhanced electrical conductivity and improved The effect of anti-friction performance and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

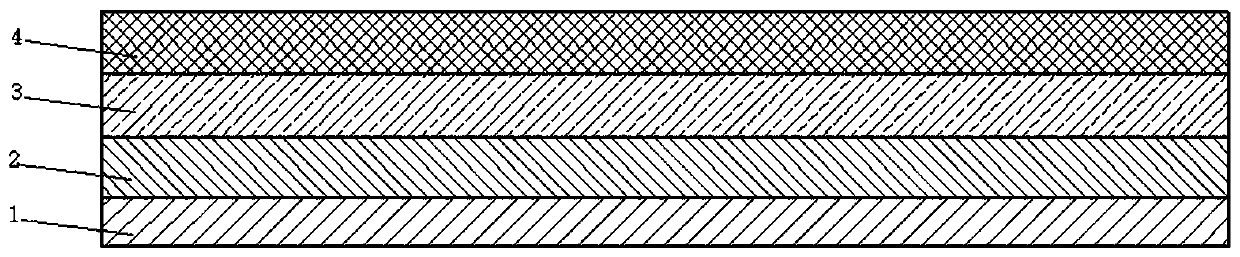

[0017] Such as figure 1 As shown, a conductive cloth tape includes a conductive cloth 3, which is one of nickel-plated conductive cloth, gold-plated conductive cloth, and aluminum foil fiber composite cloth. In this embodiment, the conductive cloth 3 is nickel-plated conductive cloth. A conductive strengthening layer 2 is bonded to the lower surface of the conductive cloth 3, and the conductive strengthening layer 2 is a conductive carbon fiber cloth with a thickness of 0.3 mm. An adhesive layer 1 is coated on the lower surface of the conductive strengthening layer 2, and the adhesive layer 1 is one of high temperature resistant polyurethane adhesive and epoxy resin AB glue. In this embodiment, the adhesive layer 1 is high temperature resistant polyurethane adhesive. A wear-resistant layer 4 is also bonded to the upper surface of the conductive cloth 3, and the wear-resistant layer 4 is nylon cloth with a thickness of 0.15 mm.

Embodiment 2

[0019] Such as figure 1 As shown, a conductive cloth tape includes a conductive cloth 3, which is one of nickel-plated conductive cloth, gold-plated conductive cloth, and aluminum foil fiber composite cloth. In this embodiment, the conductive cloth 3 is a gold-plated conductive cloth. A conductive strengthening layer 2 is bonded to the lower surface of the conductive cloth 3, and the conductive strengthening layer 2 is a conductive carbon fiber cloth with a thickness of 0.3 mm. An adhesive layer 1 is coated on the lower surface of the conductive strengthening layer 2, and the adhesive layer 1 is one of high temperature resistant polyurethane adhesive and epoxy resin AB glue. In this embodiment, the adhesive layer 1 is epoxy resin AB glue. A wear-resistant layer 4 is also bonded to the upper surface of the conductive cloth 3, and the wear-resistant layer 4 is nylon cloth with a thickness of 0.15 mm.

[0020] The present invention uses the conductive cloth 3 as the base materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com