An Embroidery Positioning Mechanism of a Computerized Embroidery Machine Using the Principle of Supercharging and Returning

A positioning mechanism and embroidery machine technology, applied in the field of embroidery machines, can solve the problems of inability, large amount of manual adjustment, unified arrangement, etc., and achieve the effect of convenient leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

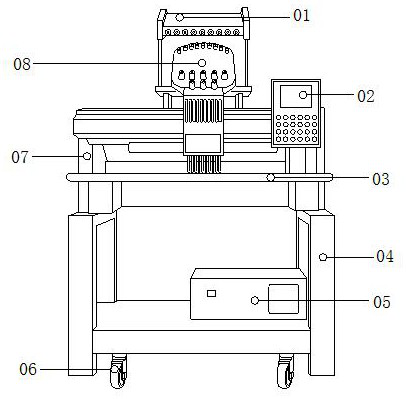

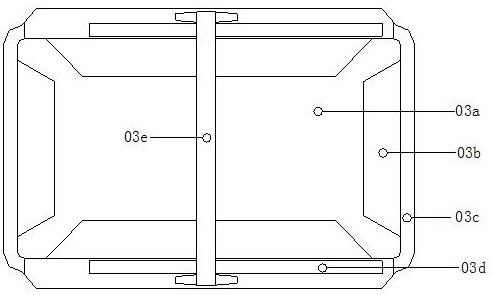

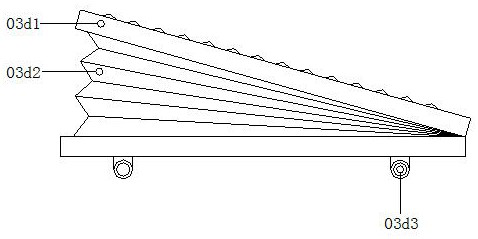

[0030] see Figure 1-Figure 7 , the present invention provides an embroidery positioning mechanism for a computer embroidery machine, the structure of which includes a thread frame 01, a controller 02, a processing platform 03, a fixed bracket 04, a servo host 05, a universal wheel 06, a vertical beam 07, and an embroidery base 08, The bottom of the vertical beam 07 is installed on the top of the processing platform 03 by buckling, and the two ends of the bottom of the processing platform 03 are connected to the top of the fixed bracket 04 by welding. The lower end of the fixed bracket 04 is provided with a servo host 05, The universal wheel 06 is provided with four, and the top is installed on the bottom of the fixed bracket 04 by buckling, the rear end of the controller 02 is installed on the right end of the vertical beam 07 by fitting, and the upper end of the vertical beam 07 is There is a thread stand 01 in the middle, the embroidery base 08 is movable and fastened with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com