Detection tool for detecting deep hole length of gear shaft

A gear shaft and deep hole technology is applied in the field of inspection tools for detecting the length of the deep hole of the gear shaft. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

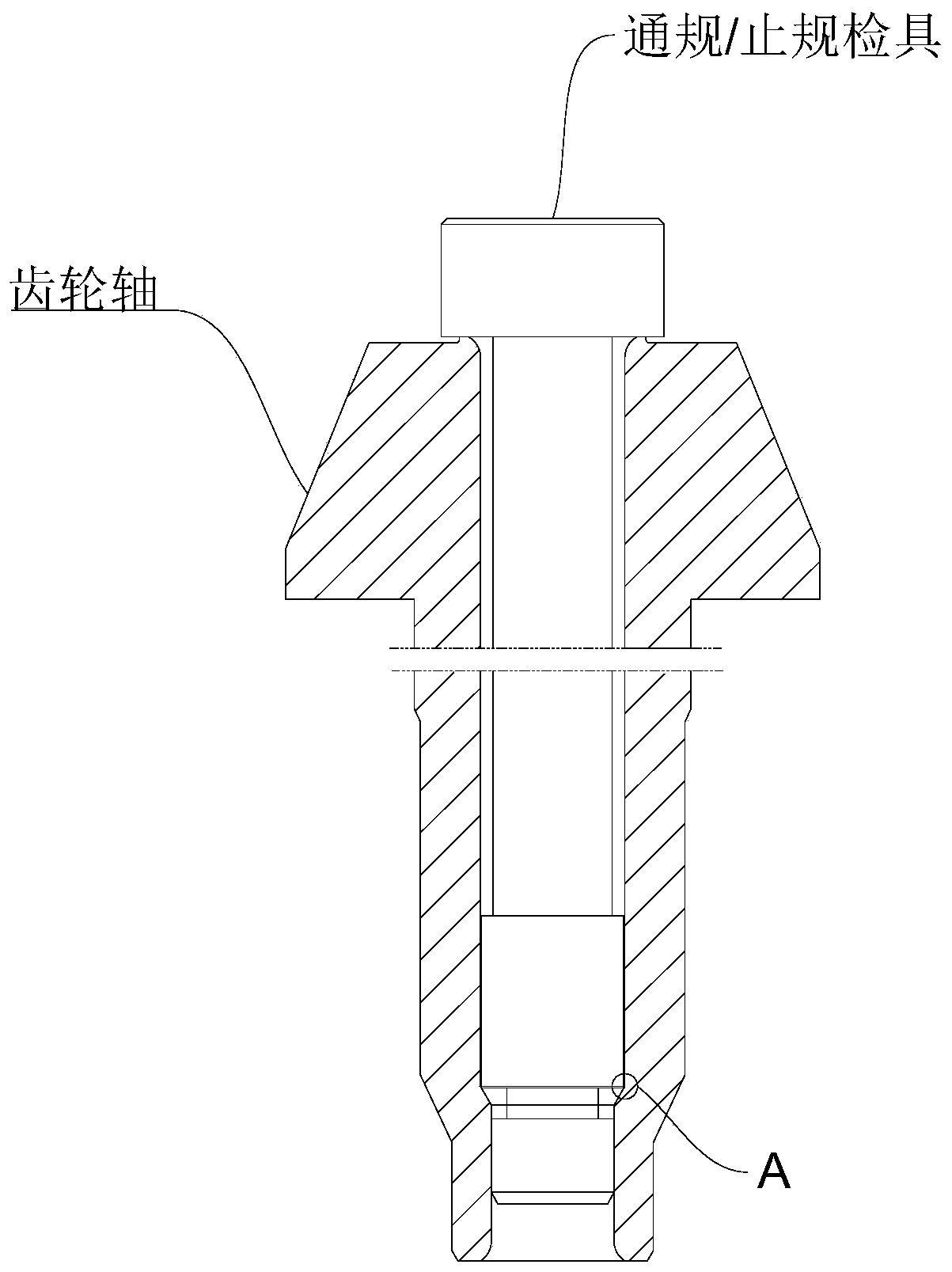

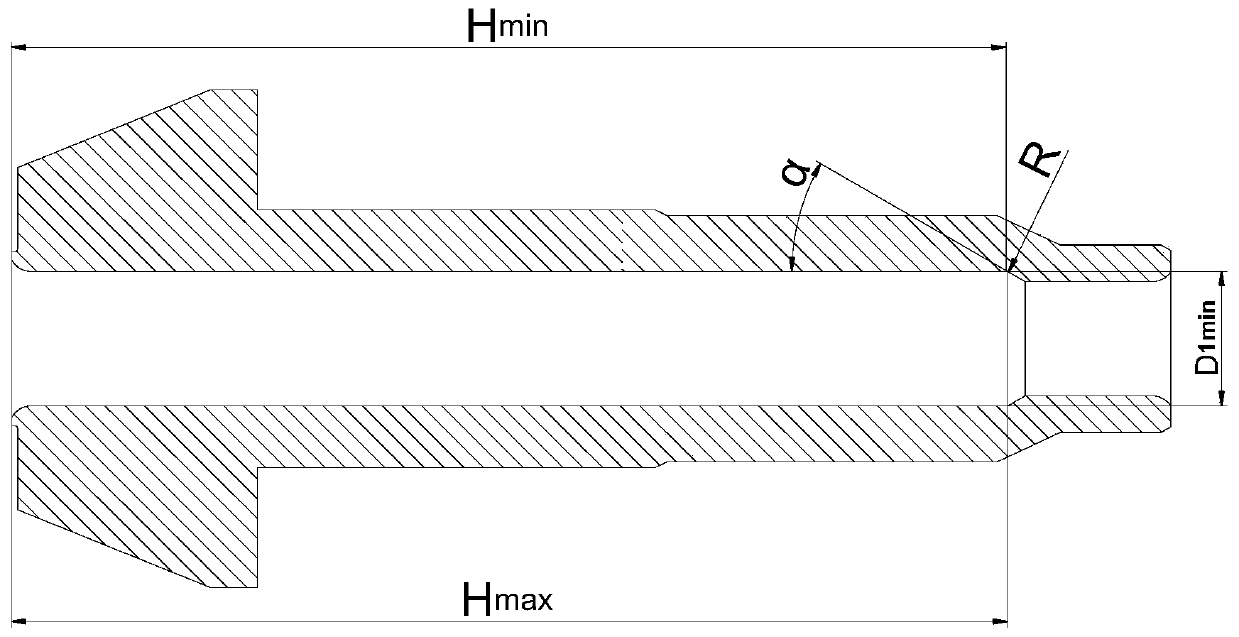

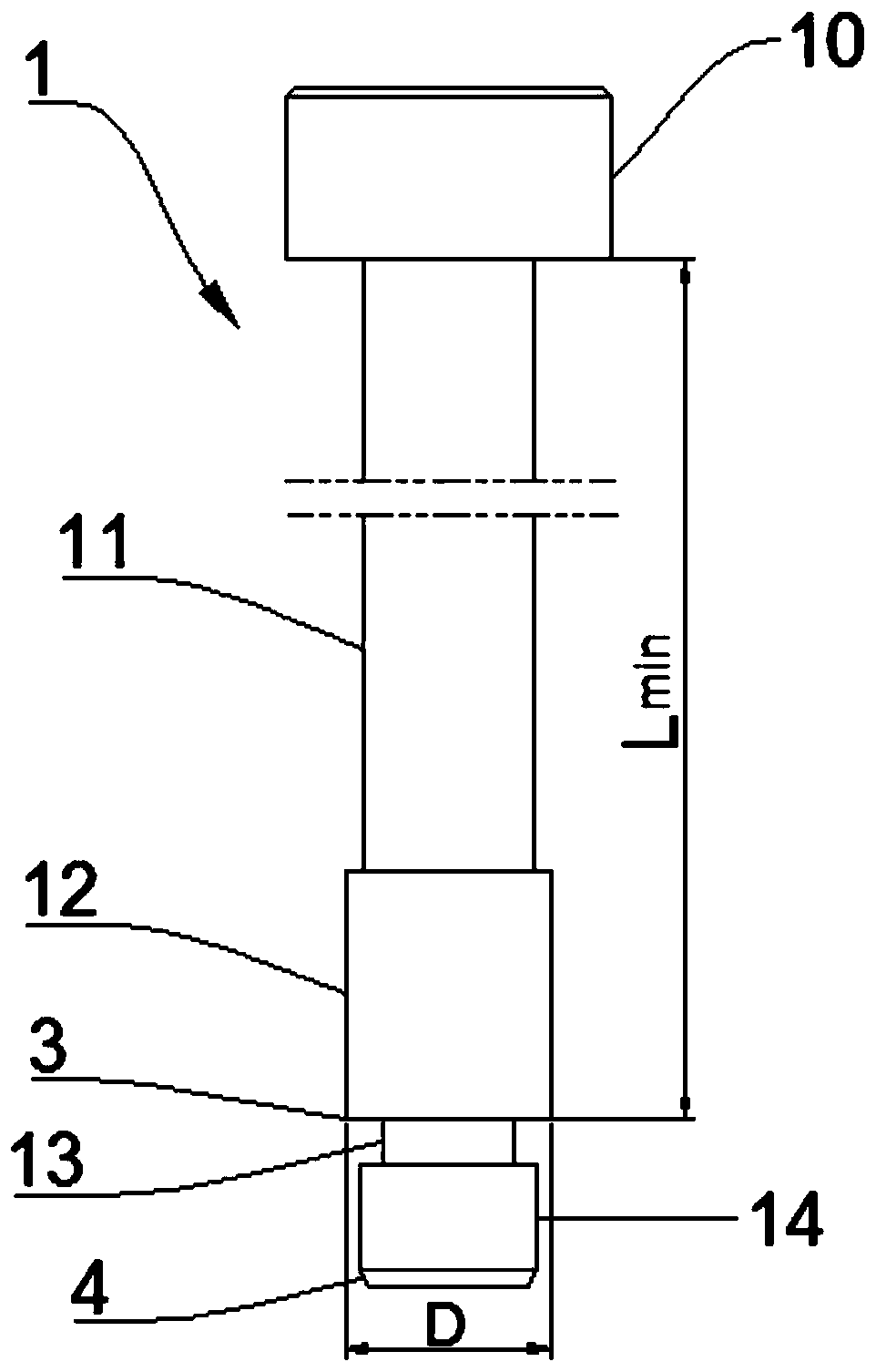

[0035] Such as figure 1 As shown, the present embodiment provides a checker 100 for detecting the length of a deep hole of a gear shaft, such as figure 2 As shown, it is used to detect whether the length of the deep hole in the gear shaft with adjacent holes is qualified. The checking tool 100 for detecting the length of the deep hole of the gear shaft includes a cylindrical through-gauge checking tool 1 and a cylindrical stop-gauge checking tool 2 . Such as image 3 As shown, the above-mentioned through-gauge inspection tool 1 is composed of an integrally formed through-end reference part 10 , a through-end first neck 11 , a through-end upper positioning part 12 , a through-end second neck 13 and a through-end lower positioning part 14 . Such as Figure 4 As shown, the above-mentioned stop gauge inspection tool 2 is composed of an integrally formed stop reference part 20 , a stop first neck 21 , a stop upper positioning part 22 , a stop second neck 23 and a stop lower pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com