Magnetic pole surface loss measuring device of variable-speed power generation motor

A technology for generating motors and surface loss, applied in the direction of measuring devices, using electrical devices, measuring heat, etc., to achieve the effect of high measurement accuracy and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

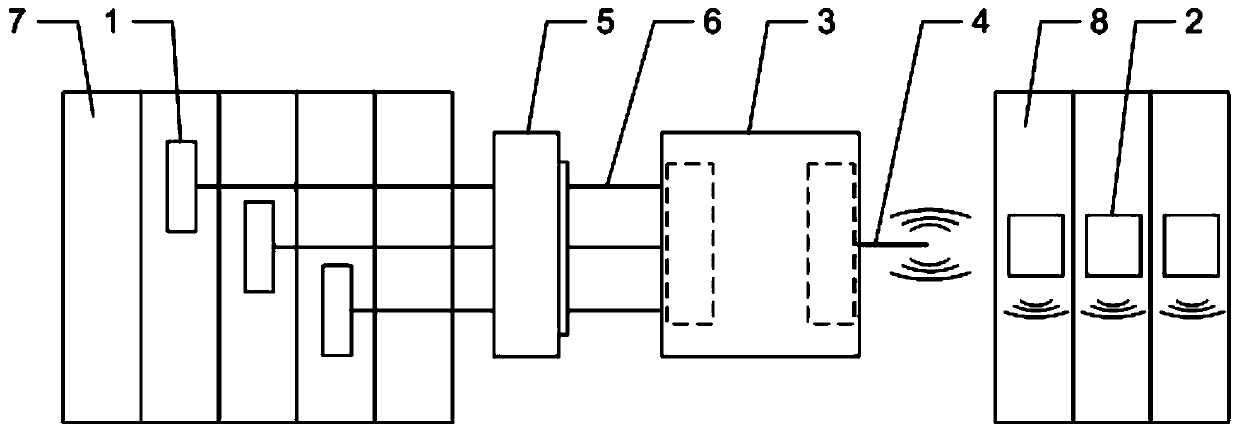

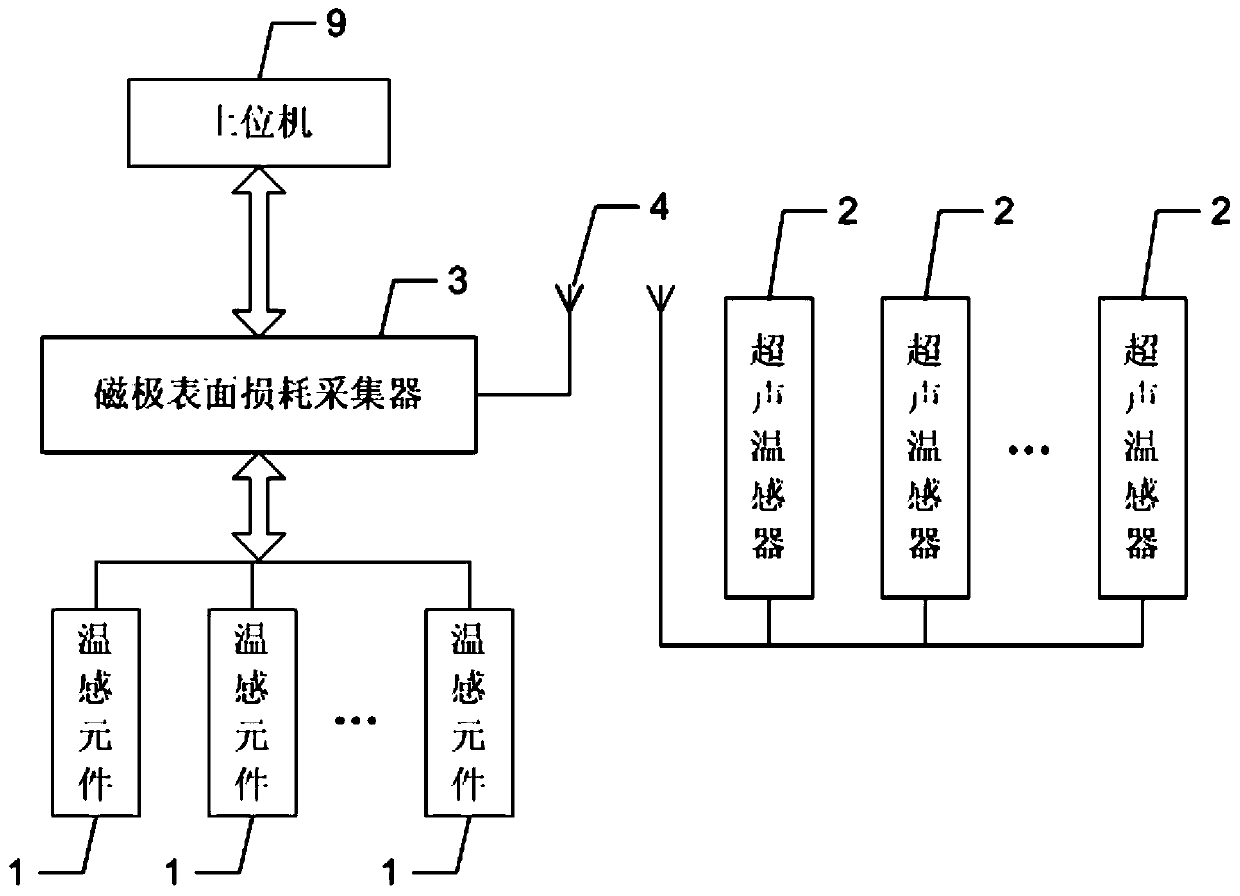

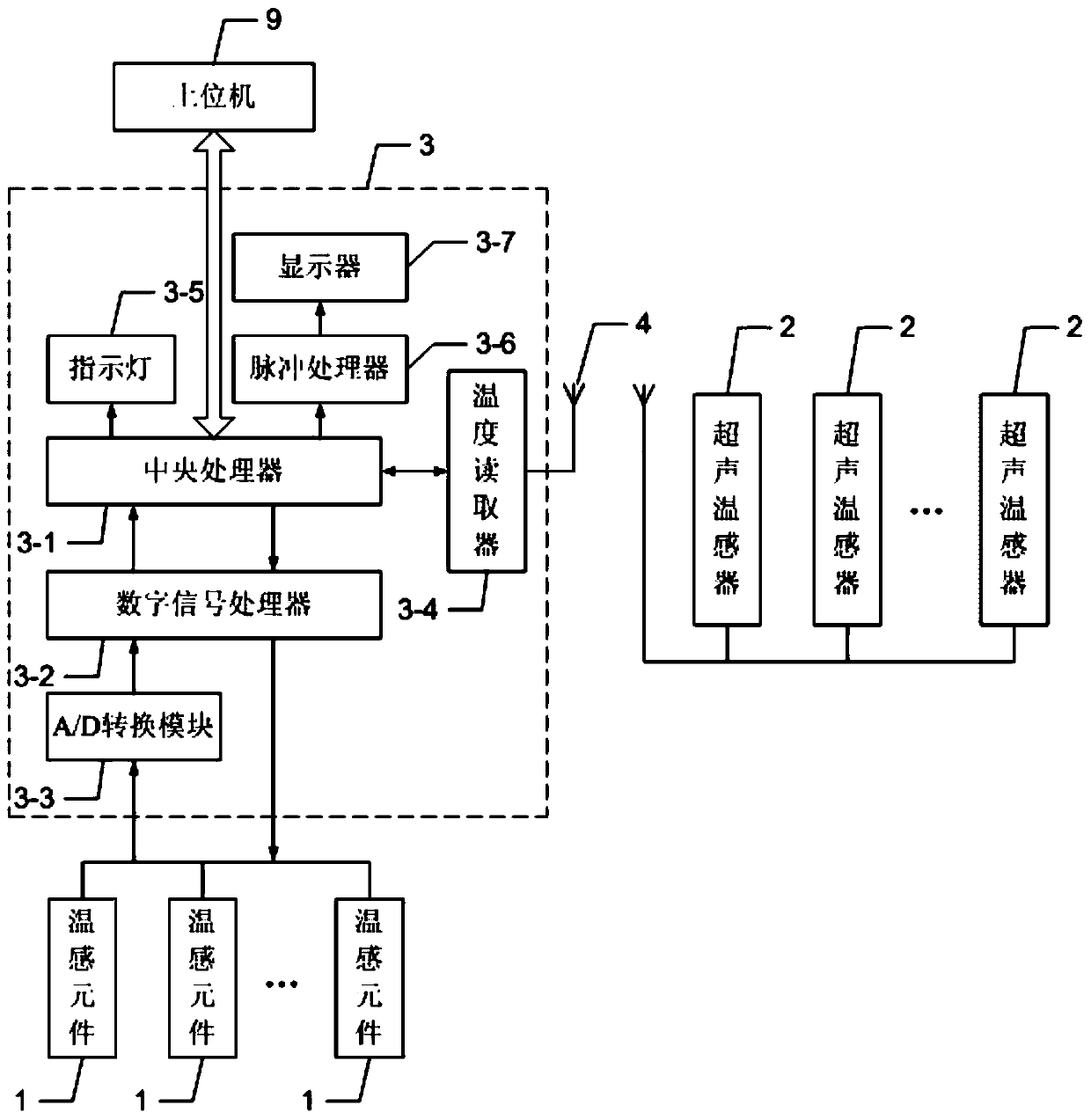

[0025] Embodiment: the rotor of the variable-speed generator motor measured by the present invention has 3 pairs of rotor poles. In the measuring device of the present invention, m=18 and n=6 are designed, that is, an ultrasonic temperature sensor 2 is surface-mounted on each rotor magnetic pole surface. Three temperature sensing elements 1 are embedded in different strands of the winding inside each rotor pole, the three temperature sensing elements 1 are used to measure the internal temperature of the rotor pole, and the one ultrasonic temperature sensor 2 is used to measure the surface of the rotor pole temperature.

[0026] The 18 temperature sensing elements 1 send the detected temperature signals to the magnetic pole surface loss collector 3 in a wired manner. In this embodiment, the temperature sensing elements 1 use platinum resistors, and the platinum resistors are designed according to the actual shape of the gap between the strands. In the structure of the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com