Deformable large-size soil box structure of true triaxial experiment of soil engineering

A true three-axis, large-scale technology, applied in the field of soil mechanics laboratory testing, to achieve the effect of improving safety and reliability, significant economic and practical value, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

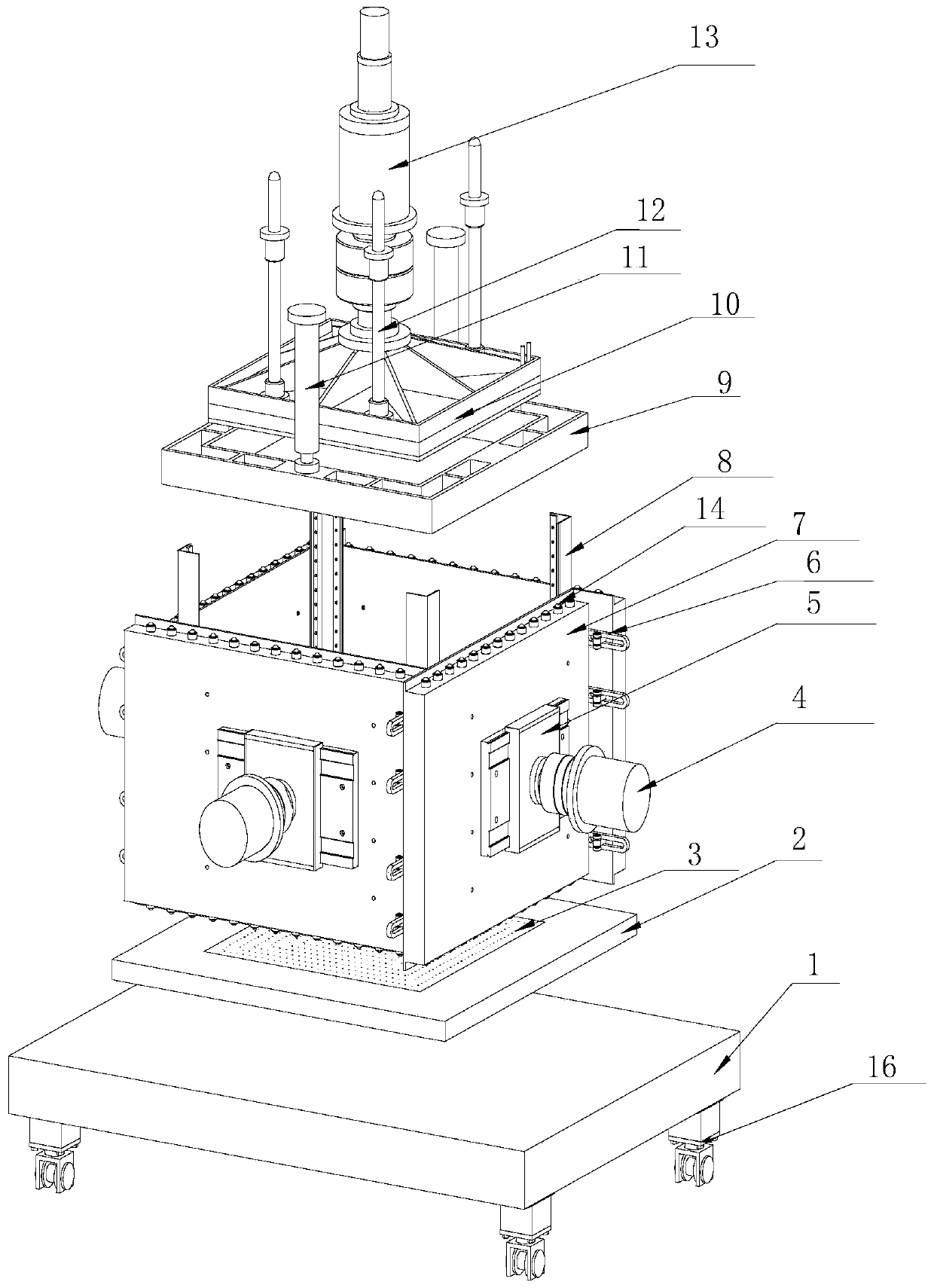

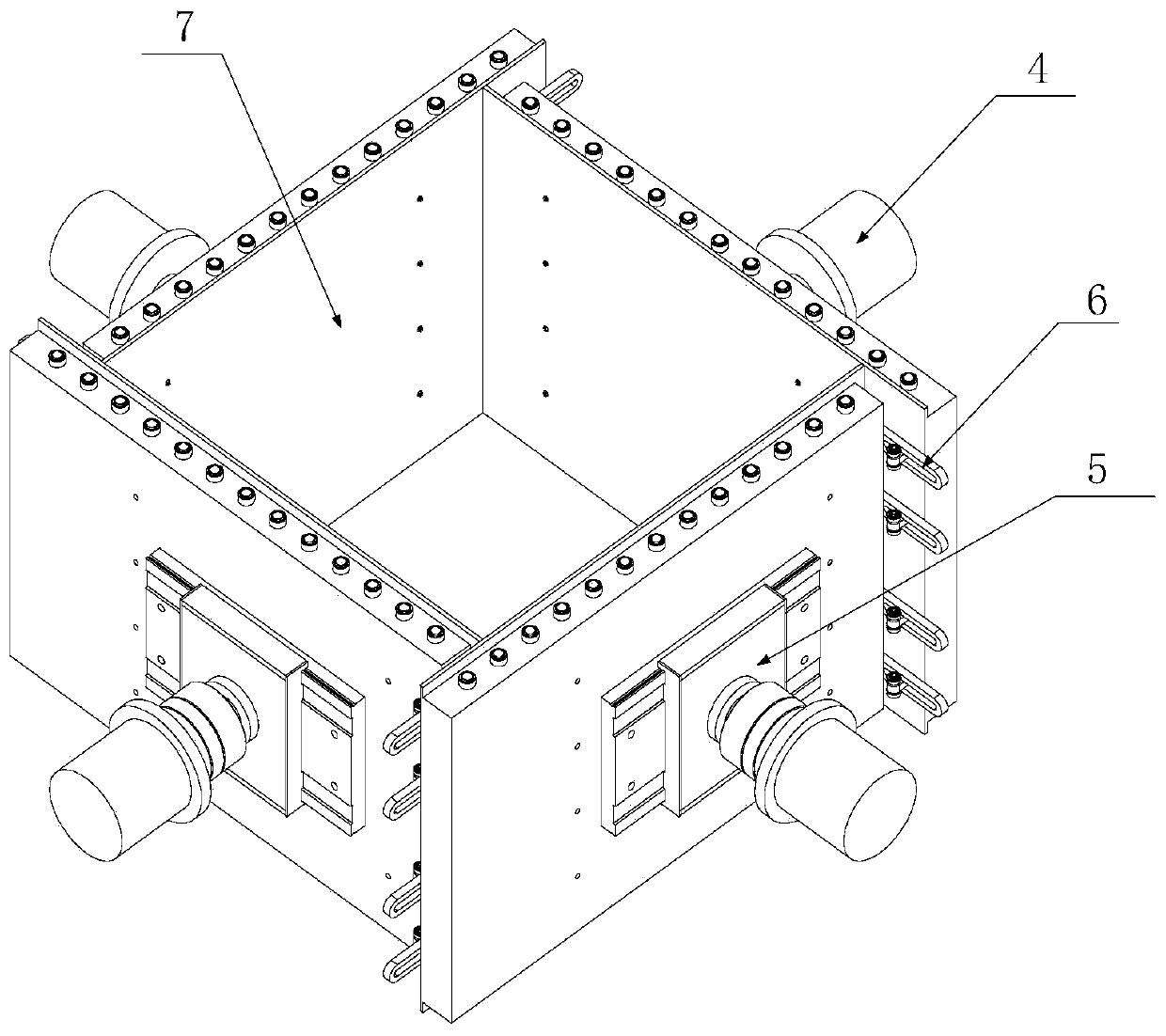

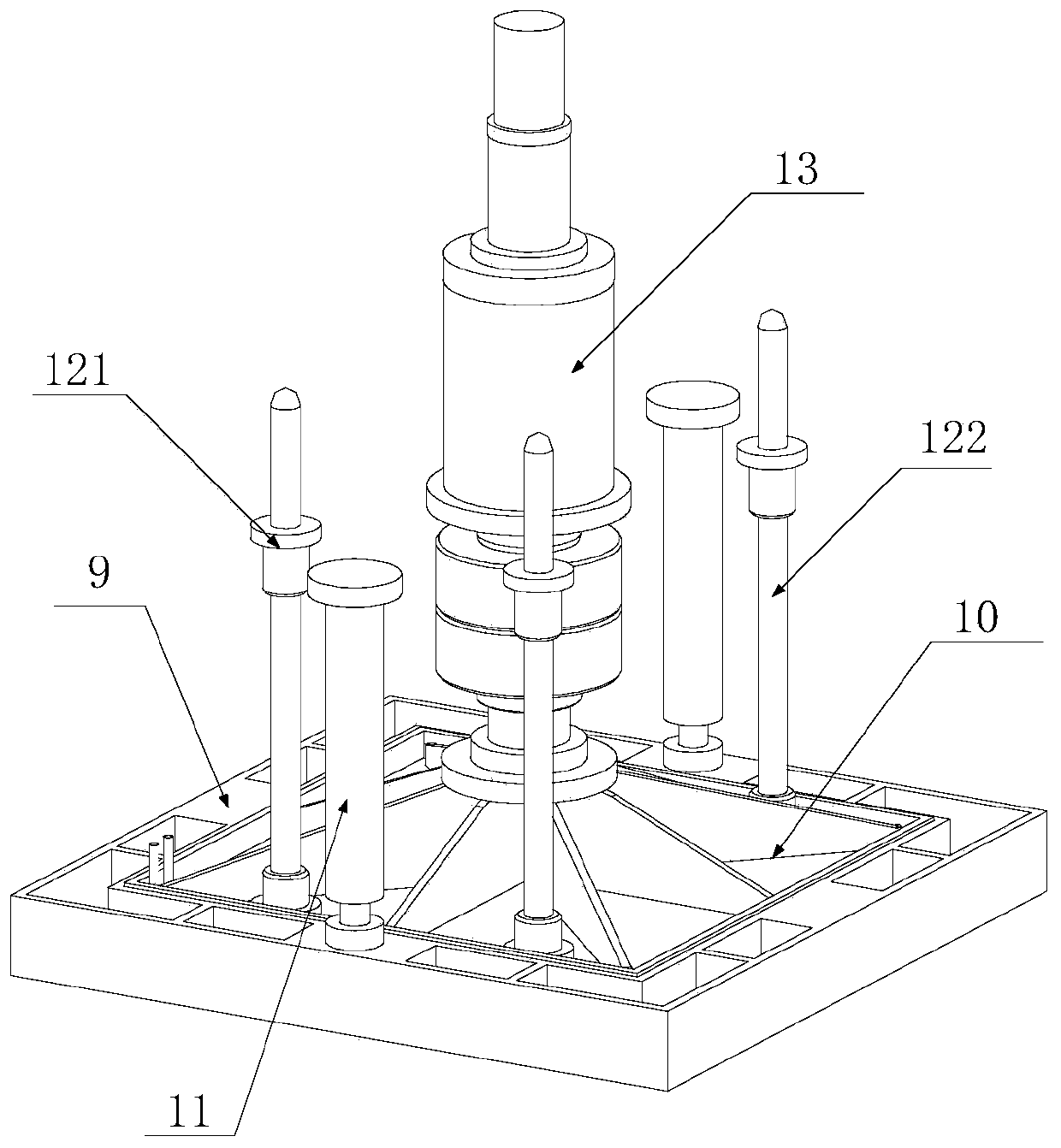

[0029] Embodiment 1, a deformable large-scale soil box structure for geotechnical true triaxial test, mainly used for geotechnical true triaxial test large-scale model test, in order to ensure that the core area of the model test is not affected by boundary conditions and sensor layout, such as figure 1 and 2 Shown is the overall schematic diagram of the soil box structure, the soil box structure includes a workbench 1, a lateral loading plate 7, a normal loading plate 10 and a bottom plate 2, and the vertical lateral loading of the four blocks bearing the horizontal load The board 7 forms the main body of the soil box. The bottom plate 2 is fixed on the workbench 1 and is located below the main body of the soil box. The bottom plate 2 is also provided with a bottom permeable plate 3. The size of the main body of the soil box is 1.2m long x 1.2m wide x high 1.0m, adjacent lateral loading plates 7 are connected by lateral guides 6 to ensure that the lateral loading plates 7 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com